Preparation method of silanization-modified molecular sieve

A molecular sieve and silanization technology, which is applied in chemical instruments and methods, molecular sieves and alkali exchange compounds, inorganic chemistry, etc., can solve the problems of difficult internal modification of molecular sieves, low silanization degree, and low silanization efficiency. Effects of reduced static and dynamic water adsorption, high degree of silanization, and improved hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

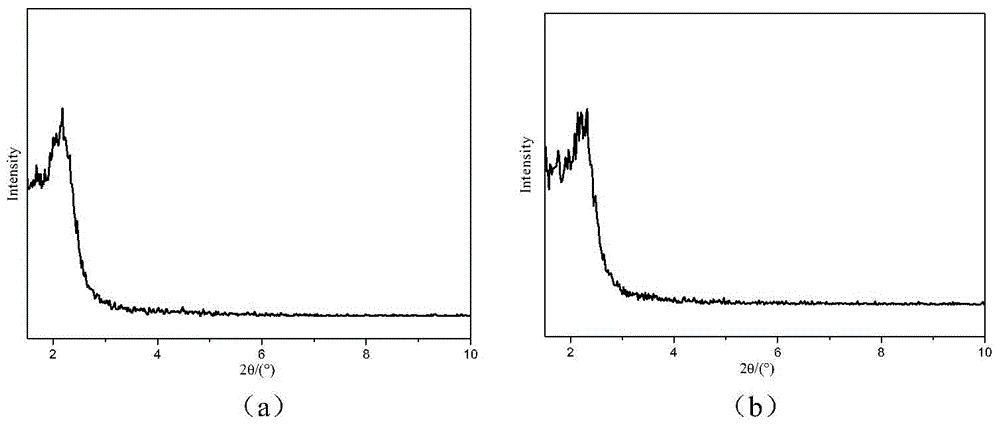

[0022] A method for preparing silanized modified molecular sieves. The molecular sieves are placed in an aqueous solution and organic acids and organic bases are alternately added for pretreatment, and the pretreated molecular sieves, accelerators and silylating agents dissolved in organic solvents are silanized Reaction, makes the molecular sieve of silanization modification, specifically comprises the following steps:

[0023] Molecular sieve pretreatment: put the molecular sieve in the aqueous solution, add organic acid and organic base alternately, adjust the pH value between 4-10 and change 2-12 times, and treat both the acidic side and the alkaline side at room temperature at 10-120 Minutes; wash the molecular sieve after acid-base treatment, and dry it at 40-120°C for 1-10 hours, then quickly transfer it to the drying equipment for use after cooling.

[0024] Molecular sieve silanization: Dissolve the silylating agent in an organic solvent, transfer it to the reactor, a...

Embodiment 1

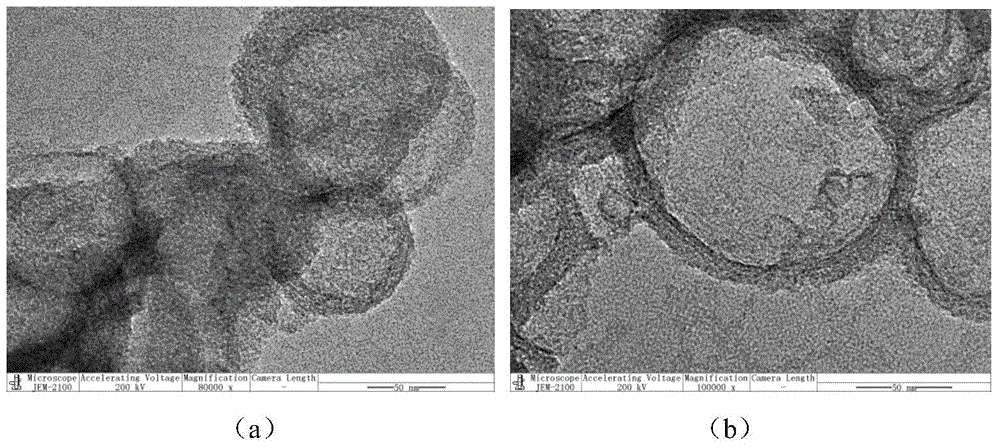

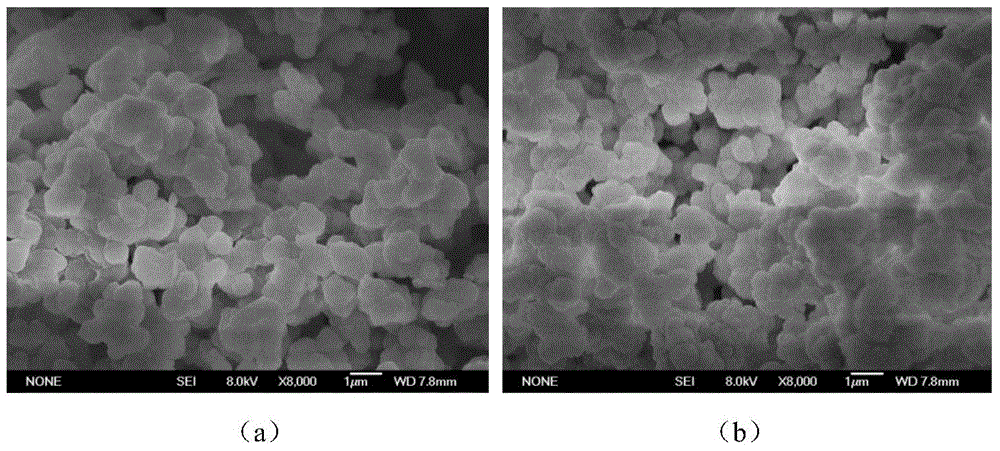

[0046] Molecular sieve pretreatment: put the synthesized HMS molecular sieve in aqueous solution, add acetic acid and carbonamide alternately, adjust the pH value to swing between 4-10 and change 5 times, and treat both the acid side and the alkaline side at room temperature for 60 minutes Then wash and transfer to a vacuum drying oven, dry at 90°C for 6 hours, and quickly transfer to a drying oven for use after cooling.

[0047] Silanization of molecular sieves: Dissolve 26.3mL of trimethylchlorosilane in 606mL of ether to prepare a solution with a mass fraction of 5%, and transfer it to a tank reactor; 5.8mL, the molar ratio of trimethylchlorosilane to molecular sieve and accelerator is 1:1.2:0.2, stir evenly; pass nitrogen gas to ensure that the air is exhausted and seal it quickly, and then at a temperature of 90°C, a pressure of 1.5MPa, and a stirring speed Under the condition of 200r / min, the constant temperature reaction was carried out for 5 hours. Cool to room temper...

Embodiment 2

[0049] Molecular sieve pretreatment: put the synthesized HMS molecular sieve in aqueous solution, add acetic acid and carbonamide alternately, adjust the pH value between 4-10 and swing twice, and treat both the acidic side and the alkaline side at room temperature for 10 minutes ; Then wash and transfer to a vacuum drying oven, dry at 40°C for 1 hour, and quickly transfer to a drying oven for use after cooling.

[0050] Silanization of molecular sieves: Dissolve 26.3mL of trimethylchlorosilane in 765mL of ether to prepare a solution with a mass fraction of 4%, and transfer it to a tank reactor; pretreated HMS molecular sieves 12.6g and triethylamine 2.9mL, the molar ratio of trimethylchlorosilane to molecular sieve and accelerator is 1:1:0.1, stir evenly; pass in nitrogen gas to ensure that the air is exhausted and seal it quickly, and then at a temperature of 30°C, a pressure of 0.5MPa, and a stirring speed Under the condition of 100r / min, constant temperature reaction for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com