Composite board produced from modified phosphorus slag and waste plastics and production method thereof

A technology of waste plastics and composite boards, which is applied in the field of building materials, can solve the problems of over-occupancy, etc., and achieve the effects of reducing pollution, good social benefits and market prospects, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

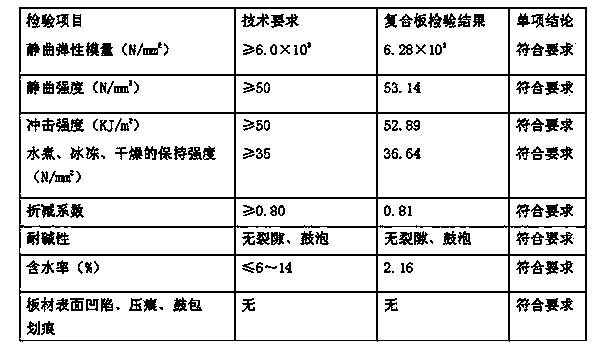

Image

Examples

Embodiment 1

[0030] Make modified phosphorus slag according to the following steps:

[0031] a. Phosphorus slag is obtained after crushing, grinding, and screening to obtain phosphorus slag fine powder; the particle size of the phosphorus slag fine powder is ≤200 μm;

[0032] b, get 0.5Kg isopropyl trioctyl pyrophosphate acyloxy titanate, 100Kg phosphorus slag fine powder and 0.5Kg liquid paraffin, mix, in 20 0 At the temperature of C, the modified phosphorus slag is obtained after stirring evenly with a high-speed mixer.

[0033] Composite boards are made in the following steps:

[0034] a. After sorting and cleaning 200Kg of waste polypropylene plastics and 200Kg of waste and old polyethylene plastics, they are crushed to less than 15mm, and mixed evenly with 300Kg of modified phosphorus slag to obtain product A.

[0035] b. Heat product A to 180 0 C~220 0 After C, the finished product can be obtained by injection molding or calendering; or put A product into the mold and heat it to ...

Embodiment 2

[0042] Make modified phosphorus slag according to the following steps:

[0043] a. Phosphorus slag is obtained after crushing, grinding, and screening to obtain phosphorus slag fine powder; the particle size of the phosphorus slag fine powder is ≤200 μm;

[0044] b, get 1.5Kg isopropyl trioleate acyloxy titanate, 100Kg phosphorus slag fine powder and 1.5Kg liquid paraffin, mix, in 20 0 At the temperature of C, the modified phosphorus slag is obtained after stirring evenly with a high-speed mixer.

[0045] Composite boards are made in the following steps:

[0046] a. After sorting and cleaning 300Kg of waste polypropylene plastics and 250Kg of waste and old polyethylene plastics, they were crushed to less than 15mm, and mixed evenly with 450Kg of modified phosphorus slag to obtain product A.

[0047] b. Heat product A to 180 0 C~220 0 After C, the finished product can be obtained by injection molding or calendering; or put A product into the mold and heat it to 180 0 C~220...

Embodiment 3

[0054] Make modified phosphorus slag according to the following steps:

[0055] a. Phosphorus slag is obtained after crushing, grinding, and screening to obtain phosphorus slag fine powder; the particle size of the phosphorus slag fine powder is ≤200 μm;

[0056] b, get 3Kg isopropyl trioleate acyloxy titanate, 100Kg phosphorous slag fine powder and 3Kg liquid paraffin, mix, in 20 0 At the temperature of C, the modified phosphorus slag is obtained after stirring evenly with a high-speed mixer.

[0057] Composite boards are made in the following steps:

[0058] a. After sorting and cleaning 500Kg of waste polypropylene plastics and 400Kg of waste and old polyethylene plastics, they were crushed to less than 15mm, and mixed evenly with 600Kg of modified phosphorus slag to obtain product A.

[0059] b. Heat product A to 180 0 C~220 0 After C, the finished product can be obtained by injection molding or calendering; or put A product into the mold and heat it to 180 0 C~220 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com