Grafted copolymer of polyisobutene and polyisoprene and preparation method thereof

A technology of polyisoprene and graft copolymer, applied in the field of graft copolymer, which can solve the problems of difficult post-processing separation, low molecular weight, slow polymerization reaction rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

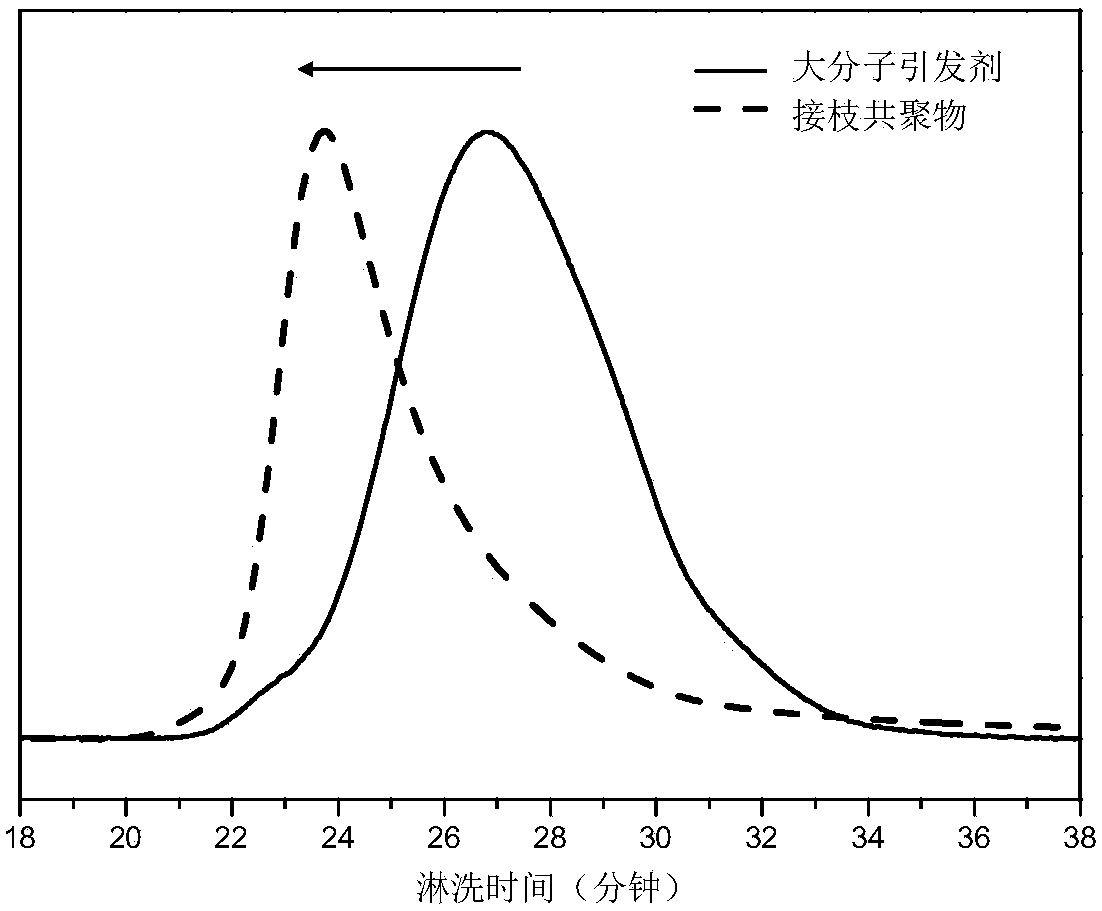

[0061] At -90°C under nitrogen protection, add 10 mL of brominated isobutylene and p-methylstyrene random copolymer (BIMS) / hexane solution (concentration: 0.1 g / mL, bromine content is 0.9 wt%) to the polymerization reactor ) and 10 mL of isoprene (IP), mix well. Under stirring, add anisole and ethyl aluminum dichloride solution to initiate IP polymerization. Among them, the molar ratio of BIMS to IP is 1.2×10 -4 , the molar ratio of anisole to IP is 3×10 -4 , the molar ratio of dichloroethylaluminum to IP is 3×10 -3 . After 30 minutes of polymerization reaction, 2 mL of NaOH / ethanol solution with a mass fraction of 2% NaOH was added to terminate the reaction; after termination, the reaction system was washed with lye and water in sequence, and repeated three times. After purification, the polymer was obtained and dried in vacuum at 40°C. Obtain PIB-g-PIP graft copolymer 0.5g, its absolute weight-average molecular weight is 1920kg / mol, molecular weight distribution index (M...

Embodiment 2

[0063] The experimental method and reaction conditions are the same as in Implementation 1, except that the amount of ethylaluminum dichloride is reduced so that the molar ratio of it to IP is 2×10 -3 . Obtain PIB-g-PIP graft copolymer 0.45g, its absolute weight-average molecular weight is 1991kg / mol, M w / M n is 2.5, and the PIP mass content is 15%; the absolute weight-average molecular weight of the main chain isobutylene-based polymer segment is 1470kg / mol; the M of the branched polyisoprene segment n It is 89kg / mol, the 1,4-structure content accounts for 93%, and there is no cyclic structure.

Embodiment 3

[0065] Under the protection of nitrogen at 0°C, add 1 mL of brominated isobutylene and p-methylstyrene random copolymer (BIMS) / hexane solution (concentration: 0.1 g / mL, bromine content: 1.6 wt%) to the polymerization reactor ), 3,5-di-tert-butyl-4-hydroxybenzoic acid n-hexadecyl and ethylaluminum dichloride solution, mixed for 1 min. Under stirring, 19 mL of isoprene (IP) / hexane solution was added to start the polymerization. Among them, the molar ratio of BIMS to IP is 2.0×10 -4 , the molar ratio of 3,5-di-tert-butyl-4-hydroxybenzoic acid n-hexadecyl to IP is 1.6×10 -3 , the molar ratio of dichloroethylaluminum to IP is 8.0×10 -3 . Polymerization was terminated after 120min, and the aftertreatment process was the same as in Example 1. Obtain PIB-g-PIP graft copolymer 0.8g, its absolute weight-average molecular weight is 1340kg / mol, M w / M n is 1.6, and the PIP mass content is 13%; the absolute weight-average molecular weight of the main chain isobutylene-based polymer s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com