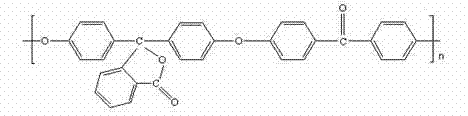

Hydrophilic polyaryletherketone blended hollow fiber ultrafilter membrane and preparation method thereof

A technology of polyaryletherketone and phenolphthalein-based polyaryletherketone is applied in the field of hydrophilic polyaryletherketone blended hollow fiber ultrafiltration membrane and its preparation, and achieves improved hydrophilicity and anti-pollution ability, good heat resistance performance, the effect of weakening the swelling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

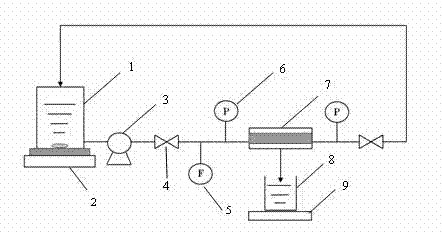

Method used

Image

Examples

Embodiment 1

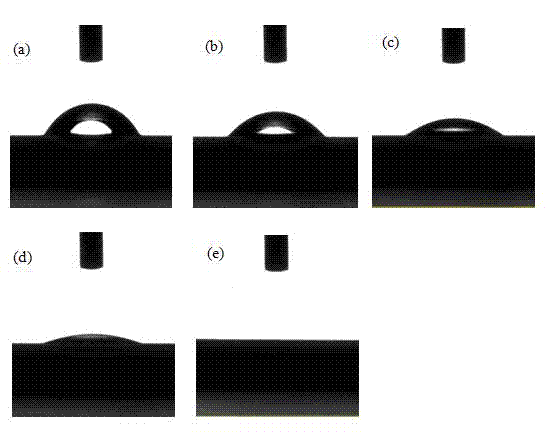

[0067] 100 grams of phenolphthalein-based polyaryl ether ketone (PEK-C), 22 grams of polyvinylpyrrolidone PVP (K85), add 420 grams of dimethyl sulfoxide and 12 grams of polyethylene glycol (600) to a mixed solvent of 80 Stir at ℃ for 24 hours to form a homogeneous blended polymer film casting solution. After that, the casting liquid was filtered through a stainless steel filter and placed in a material tank at a temperature of 50°C for vacuum degassing. After the bubbles are completely removed, the hollow fiber ultrafiltration membrane is prepared by the dry-wet phase conversion process. The casting liquid is extruded through the spinneret, after passing through a 2cm air gap, it is vertically immersed in a gel bath at 50℃ for phase separation and solidification, and then introduced into the winding tank through a winding wheel with a speed of 6m / min. The core liquid is composed of It is pure water, forming a nascent hollow fiber ultrafiltration membrane. The nascent hollow f...

Embodiment 2

[0071] 100g of phenolphthalein-based polyaryletherketone (PEK-C), 20g of polyvinylpyrrolidone PVP (K90), respectively add 392g of N-methylpyrrolidone and 15g of pure water into a mixed solvent, and stir at 80℃ for 36 hours , The formation of a homogeneous blended polymer film casting solution. After that, the casting liquid was filtered through a stainless steel filter and placed in a material tank at a temperature of 60°C for vacuum degassing. After the bubbles are completely removed, the hollow fiber ultrafiltration membrane is prepared by the dry-wet phase conversion process. The casting liquid is extruded through the spinneret, and after a 1cm air gap, it is vertically immersed in a 60℃ gel bath for phase separation and solidification, and then introduced into the winding tank through a winding wheel with a speed of 7m / min. The core liquid is composed of It is pure water, forming a nascent hollow fiber ultrafiltration membrane. The nascent hollow fiber membrane is immerse...

Embodiment 3

[0075] The hollow fiber ultrafiltration membrane was prepared according to the casting solution formula of Example 2. The spinning process conditions are: the air gap is 2cm, the spinning speed is 10m / min, the gel bath temperature is 60°C, and the core liquid composition is a mixed solution of N-methylpyrrolidone and water with a mass concentration of 80%. The nascent hollow fiber membrane is immersed in deionized water at 25°C for 48 hours for finalization, and washed with clean water. The cleaned membrane is immersed in a sodium persulfate solution with a concentration of 8%, and reacted at 85°C for 4 hours to carry out post-treatment for hydrophilicity retention to obtain a phenolphthalein-based polyaryletherketone blend hollow with stable hydrophilicity Fiber ultrafiltration membrane.

[0076] After measuring its separation performance, at a temperature of 25°C and a transmembrane pressure difference of 0.1 MPa, the membrane's pure water flux is 695L / m 2 .hr. The water cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com