Polypropylene composite material with characteristics of low odor, scratch resistance and low gloss, and preparation method thereof

A composite material and scratch-resistant technology, applied in the field of polypropylene composite material and its preparation, can solve the problems of complicated process, influence on the mechanical properties of materials, low odor, etc., achieve simple and easy control of the preparation process, and increase the blending compatibility. , the effect of improving scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-11 and comparative example 1-7

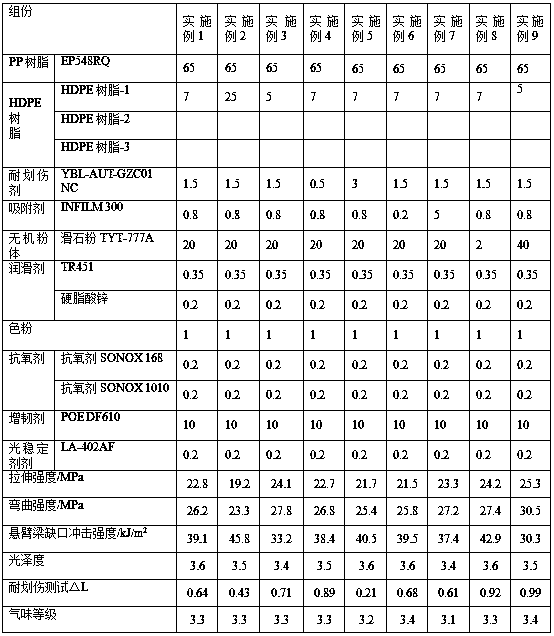

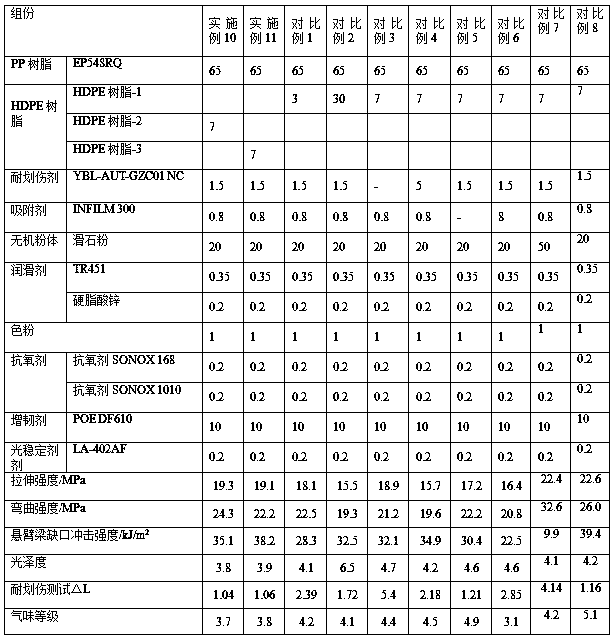

[0056] Examples 1-11 and Comparative Examples 1-7: Preparation of Polypropylene Composite Materials with Low Odor, Scratch Resistance and Low Gloss Properties

[0057] Put PP resin, HDPE resin, anti-scratch agent, adsorbent, inorganic powder, antioxidant, lubricant, toughening agent, and other processing aids into the mixer in sequence according to the ratio in Table 2, and mix for 3min-5min. Obtain the premixed material; pour the obtained premixed material into the hopper of the extruder, enter the screw barrel of the extruder through the feeding port, and extrude and granulate after kneading, plasticizing and melting in the extruder, extruding The structural feature of the machine is that the water injection port is opened in the 2-5 zone to inject pure water, and the double vacuum system in the 5-8 zone and the 8-11 zone is vacuumed; the vacuum degree of the double vacuum system is ≥0.08MPa, and the water injection ratio is resin 1%-10% of the total weight of the granulated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com