Preparation method of industrial alkali lignin/polyvinyl alcohol cross-linked thin film

A technology of industrial alkali lignin and polyvinyl alcohol, applied in the field of polymer film materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

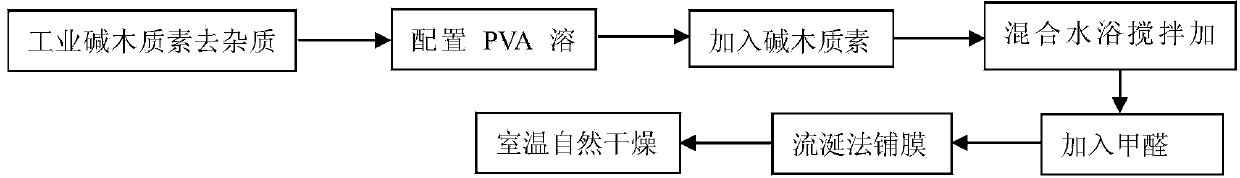

Method used

Image

Examples

Embodiment 1

[0018] Industrial alkali lignin dissolves a certain amount of crude lignin with 0.1moL / L NaOH solution, stirs it under the mixer for 2 hours, and then centrifuges it with a centrifuge. After filtering the obtained liquid through a layer of filter cloth, it is directly spray dried with a spray dryer , the resulting solid powder is the alkali lignin required for the experiment.

[0019] Weigh 8g of PVA and 2g of alkali lignin into a three-necked flask, add 195g of water, heat and stir in a water bath at 90°C for 50min. Then add 2 mL of formaldehyde with a mass fraction of 37% to 40%, and carry out the crosslinking reaction for 30 minutes. After the stirring was completed, vacuum defoaming was performed at room temperature, and a film was cast on a glass plate. Dry naturally at room temperature to obtain the desired film. After cooling for a while, vacuum defoaming, pour it on a glass plate, then scrape it with a scraper to form a film, and after natural drying, peel off the fi...

Embodiment 2

[0022] Weigh 7g of PVA and 3g of alkali lignin into a three-necked flask, add 195g of water, heat and stir in a water bath at 90°C for 50min. Then add 2 mL of formaldehyde with a mass fraction of 37% to 40%, and carry out the crosslinking reaction for 30 minutes. After the stirring was completed, vacuum defoaming was performed at room temperature, and a film was cast on a glass plate. Dry naturally at room temperature to obtain the desired film. After cooling for a while, vacuum defoaming, pour it on a glass plate, then use a scraper to scrape it into a film, and after natural drying, peel off the film to obtain an alkali lignin / PVA co-film.

[0023] Tensile properties of the film The elongation at break is 182.26%, the tensile strength is 32.62MPa, and the oxygen permeability is 15.80×10 -5 cm 3 / m 2 ·d·Pa, carbon dioxide air permeability 11.40×10 -5 cm 3 / m 2 · d · Pa.

Embodiment 3

[0025] Weigh 6g of PVA and 4g of alkali lignin into a three-necked flask, add 195g of water, heat and stir in a water bath at 90°C for 50min. Then add 2 mL of formaldehyde with a mass fraction of 37% to 40%, and carry out the crosslinking reaction for 30 minutes. After the stirring was completed, vacuum defoaming was performed at room temperature, and a film was cast on a glass plate. Dry naturally at room temperature to obtain the desired film. After cooling for a while, vacuum defoaming, pour it on a glass plate, then scrape it with a scraper to form a film, and after natural drying, peel off the film to obtain an alkali lignin / PVA film.

[0026] Tensile properties of the film The elongation at break is 158.38%, the tensile strength is 25.93MPa, and the oxygen permeability is 13.1×10 -5 cm 3 / m 2 ·d·Pa, carbon dioxide gas permeability 9.35×10 -5 cm 3 / m 2 · d · Pa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com