High-strength and high-tenacity plastic building template

A construction template and tough plastic technology, which is applied in the direction of architecture, building structure, formwork/formwork components, etc., can solve the problem that the reinforcement effect of chopped glass fiber is not as good as that of fiber mesh, the interface peeling of fiber mesh and plastic board, and the construction template Insufficient improvement of strength and other problems, to overcome interfacial peeling, improve interfacial bond strength, and improve rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

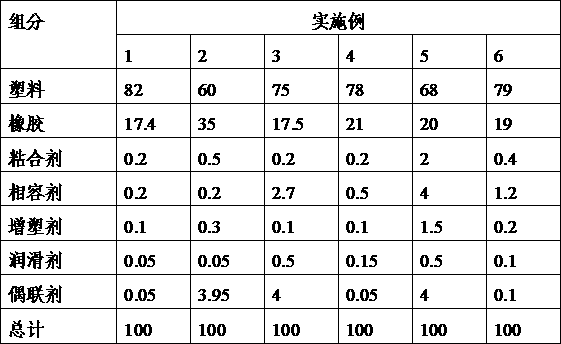

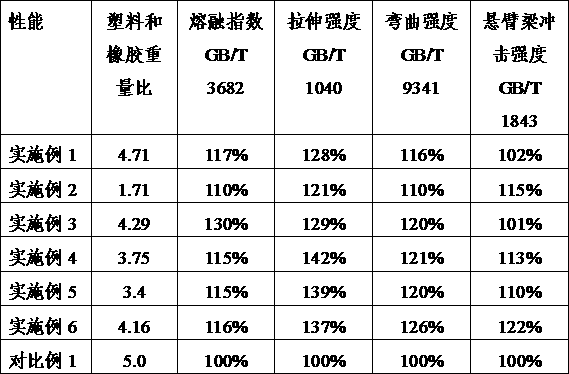

[0026] The invention is a high-strength and high-toughness plastic building template, which is composed of a plastic plate and at least one layer of glass fiber grid cloth embedded in the plastic plate. Among them, the composition of the plastic sheet includes plastic, rubber and additives, and the additives include adhesives, compatibilizers, plasticizers, lubricants and coupling agents. See Table 1 for the compositions and specific weight ratios of the plastic plates of Examples 1 to 6.

Embodiment 1

[0028] In Example 1, the number of layers of glass fiber grid cloth embedded in the plastic plate is one layer, and the glass fiber grid is parallel to the surface of the plastic plate. Each square meter of glass fiber mesh cloth contains 280g of glass fiber, and the glass fiber mesh cloth is located at a depth of 0.2~8mm from one side of the plastic building formwork.

Embodiment 2

[0029] In Example 2, the number of layers of glass fiber grid cloth embedded in the plastic plate is two, and the glass fiber grid is parallel to the surface of the plastic plate. And each square meter of upper and lower glass fiber mesh cloth contains 90g of glass fiber, the upper glass fiber mesh cloth is located at a depth of 0.2~8mm from the plastic building formwork, and the lower glass fiber mesh cloth is located at a distance of 0.2~8mm from the plastic building formwork. At the depth of 0.2~8mm on the lower surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com