High/low temperature-resistant nylon composite material and preparation method thereof

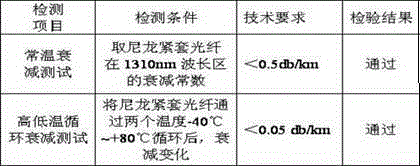

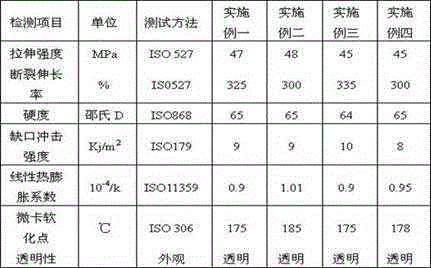

A nylon composite material with high and low temperature resistance technology, applied in the field of optical fiber tight sleeve material, can solve the problems of no patent report, single product model, high thermal expansion coefficient, etc., and achieve the effect of improving transparency, high modulus, and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

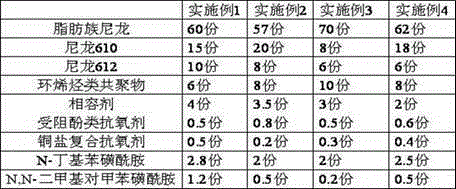

[0025] Embodiments 1 to 4: A high and low temperature resistant nylon composite material, the low and high temperature resistant nylon composite material is composed of the following components, as shown in Table 1:

[0026] Table 1

[0027]

[0028] The above-mentioned cyclic olefin copolymers are selected from 3 ethylene and norbornene copolymer TOPAS resin;

[0029] The above-mentioned compatibilizer is selected from maleic anhydride grafted amorphous polyolefin, the grafting rate is 0.8%-1.5%, and its melt index is 1-10g / 10min;

[0030] The above-mentioned plasticizer is selected from N-butylbenzenesulfonamide and N,N-dimethyl-p-toluenesulfonamide.

Embodiment 1

[0031] The cyclic olefin copolymer of embodiment 1 is selected from 6013F produced by German TAP company, the cyclic olefin copolymer of embodiment 2 is selected from Japan Polyplastics 6013, and the cycloolefin copolymer of embodiment 3 is selected from Japan Polyplastics The company's 5013, the cyclic olefin copolymer of embodiment 4 is selected from the 6017 of Polyplastics Corporation of Japan.

[0032] A preparation method for the above-mentioned high and low temperature resistant nylon composite material, comprising the following steps: 55-85 parts of the aliphatic nylon 12, 10-25 parts of nylon 610, 5-10 parts of nylon 612, cycloolefin 1-15 parts of copolymer, 0.5-5 parts of compatibilizer, 0.1-1 part of hindered phenol antioxidant, 0.1-0.5 part of copper salt composite antioxidant, 2-5 parts of N-butylbenzenesulfonamide and Mix 0.2-5 parts of N,N-dimethyl-p-toluenesulfonamide evenly in a closed mixer, release it after 3-10 minutes, granulate it through a twin-screw ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com