Heat-resistant, high-strength, low-smoke, halogen-free and flame-retardant sheathing material for optical cables, and preparation method of sheathing material

A flame-retardant sheath and high-strength technology, which is applied in the field of sheath materials for optical cables and its preparation, can solve the problems of low strength and high change rate

Inactive Publication Date: 2019-03-29

上海至正新材料有限公司

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] At present, this type of sheathing material for optical cables has low strength and high change rate of h

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Login to View More

Abstract

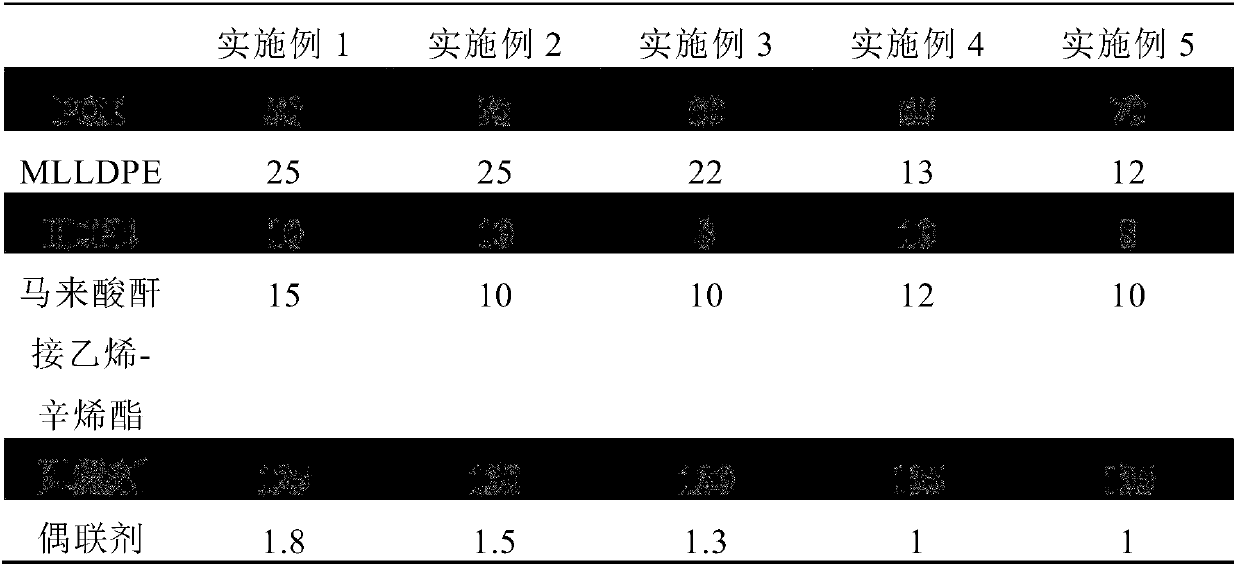

The invention discloses a heat-resistant, high-strength, low-smoke, halogen-free and flame-retardant sheathing material for optical cables, and a preparation method of the sheathing material. The sheathing material is prepared from the following components in parts by weight: 80-90 parts of polyolefin resin, 10-20 parts of a compatibilizer, 120-140 parts of a flame retardant, 1-2 parts of a coupling agent, 0.5-1 part of an antioxidant and 4-6 parts of a lubricant, wherein the polyolefin resin is prepared from the following components: a polyolefin elastomer (POE), metallocene modified linear low density polyethylene (MLLDPE) and high density polyethylene (HDPE), and the weight ratio of the polyolefin elastomer to the metallocene modified linear low density polyethylene to the high densitypolyethylene is equal to (50-70) to (12-25) to (8-10).

Description

technical field [0001] The invention relates to a sheathing material for an optical cable and a preparation method thereof, in particular to a heat-resistant, high-strength, low-smoke, halogen-free, flame-retardant sheathing material for an optical cable and a preparation method thereof. Background technique [0002] With the maturity of optical fiber transmission technology and the lower and lower price of optical fiber, the traditional coaxial cable transmission is becoming more and more unsuitable for the development of today's optoelectronic network. As the carrier of information, optical fiber has the advantages of small transmission loss and long transmission distance. , working frequency bandwidth, strong anti-interference ability and other advantages, making it the most ideal communication carrier for optoelectronic networks. Optical fibers are made of extremely pure quartz. Only single-mode optical fiber is used in optical fiber cable television, the cladding diame...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L23/08C08L23/06C08L51/06C08K3/22C08K3/26C08K5/134C08K5/526C08K13/02

CPCC08K2003/2224C08K2003/2227C08K2003/265C08L23/0815C08L2201/02C08L2201/08C08L2201/22C08L2203/20C08L2205/025C08L2205/035C08L2207/062C08L23/06C08L51/06C08K3/22C08K3/26C08K5/1345C08K5/526C08K13/02

Inventor 施祥宋刚翁文彪李现春

Owner 上海至正新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com