Thermal deformation resisting assistant for injection molding processing of laptop computer case

A notebook computer, injection molding technology, applied in the field of injection molding, can solve the problems of limited thermal deformation performance, that is, low thermal deformation temperature, difficult to achieve ultra-thin design, etc., to achieve the effect of improving powderability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

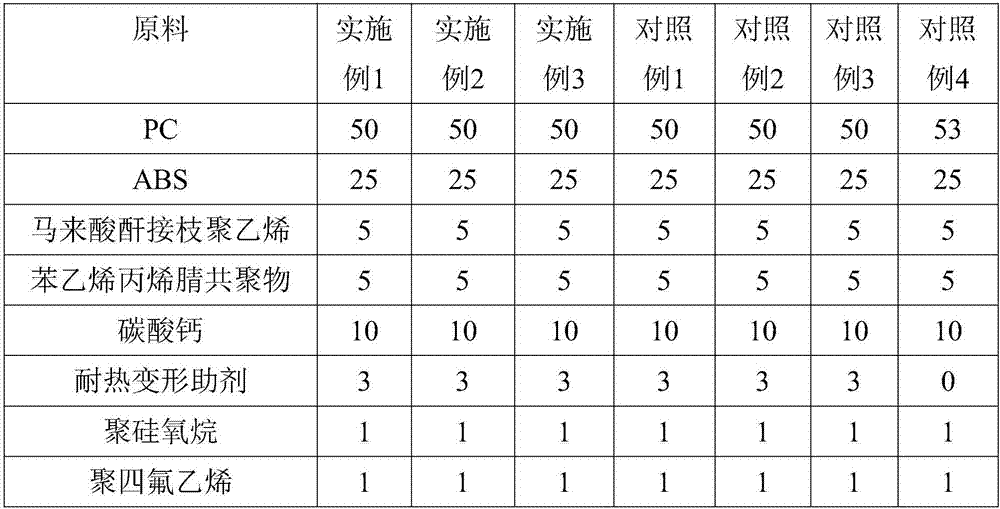

Examples

Embodiment 1

[0025] (1) Heat 100g of absolute ethanol to reflux and keep stirring, then add 10g triallyl cyanurate and 10g zinc dimethacrylate, continue to reflux and keep stirring for 3h, then add 25g fine silica aerogel , Reflux and keep stirring again for 2 hours, the resulting mixture is sent to a spray dryer after being concentrated under reduced pressure, and the dried particles are made into fine powder by a pulverizer to obtain a modified silica aerogel;

[0026] (2) Heat 10g ultrafine magnesium oxide, 3g molecular sieve micropowder and 2g asbestos wool to 115-125℃, keep and mix for 10min, then add 3g diphenylmethane bismaleimide and 0.5g titanate coupling agent, continue Incubate and mix at 115-125°C for 30 minutes, and cool to room temperature under grinding to obtain additives;

[0027] (3) Fully mix the modified silica aerogel and additives, and send the resulting mixture into a mixer, and mix at 130-140°C for 10 minutes, cool to room temperature naturally after discharge, and final...

Embodiment 2

[0030] (1) Heat 100g of absolute ethanol to reflux and keep stirring, then add 10g triallyl cyanurate and 10g zinc dimethacrylate, continue to reflux and keep stirring for 3h, then add 25g fine silica aerogel , Reflux and keep stirring again for 2 hours, the resulting mixture is sent to a spray dryer after being concentrated under reduced pressure, and the dried particles are made into fine powder by a pulverizer to obtain a modified silica aerogel;

[0031] (2) Heat 10g ultrafine magnesium oxide, 3g molecular sieve micropowder and 2g asbestos wool to 115-125℃, keep and mix for 10min, then add 3g diphenylmethane bismaleimide and 0.5g titanate coupling agent, continue Incubate and mix at 115-125°C for 30 minutes, and cool to room temperature under grinding to obtain additives;

[0032] (3) Fully mix the modified silica aerogel and additives, and send the resulting mixture into a mixer, and mix at 130-140°C for 10 minutes, cool to room temperature naturally after discharge, and final...

Embodiment 3

[0036] (1) Heat 80g of absolute ethanol to reflux and keep stirring, then add 5g triallyl cyanurate and 5g zinc dimethacrylate, continue to reflux and keep stirring for 2h, then add 20g fine silica aerogel , Reflux and keep stirring again for 2 hours, the resulting mixture is sent to a spray dryer after being concentrated under reduced pressure, and the dried particles are made into fine powder by a pulverizer to obtain a modified silica aerogel;

[0037] (2) Heat 5g ultrafine magnesia, 5g molecular sieve micropowder and 1g asbestos wool to 115-125°C and keep mixing for 10min, then add 2g diphenylmethane bismaleimide and 0.5g titanate coupling agent, continue Incubate and mix at 115-125°C for 15 minutes, and cool to room temperature under grinding to obtain additives;

[0038] (3) Fully mix the modified silica aerogel and the additives, and send the resulting mixture into a mixer, and mix at 130-140°C for 10 minutes, and cool to room temperature naturally after discharge, and final...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com