Blend polymer containing ethylene/tetrafluoroethylene copolymer, molded body of said blend polymer, back sheet for solar cells, and method for producing said molded body

A technology of tetrafluoroethylene copolymer and mixed polymer, which is applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve problems such as deformation, and achieve the effects of high heat distortion temperature, excellent weather resistance, and excellent heat deformation resistance

Inactive Publication Date: 2015-09-02

AGC INC

View PDF8 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in recent years, in applications such as back sheets of solar cells and coating materials for heat-resistant electric wires, it is expected that there will be problems with deformation under high heat, and it is required to increase the heat distortion temperature.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

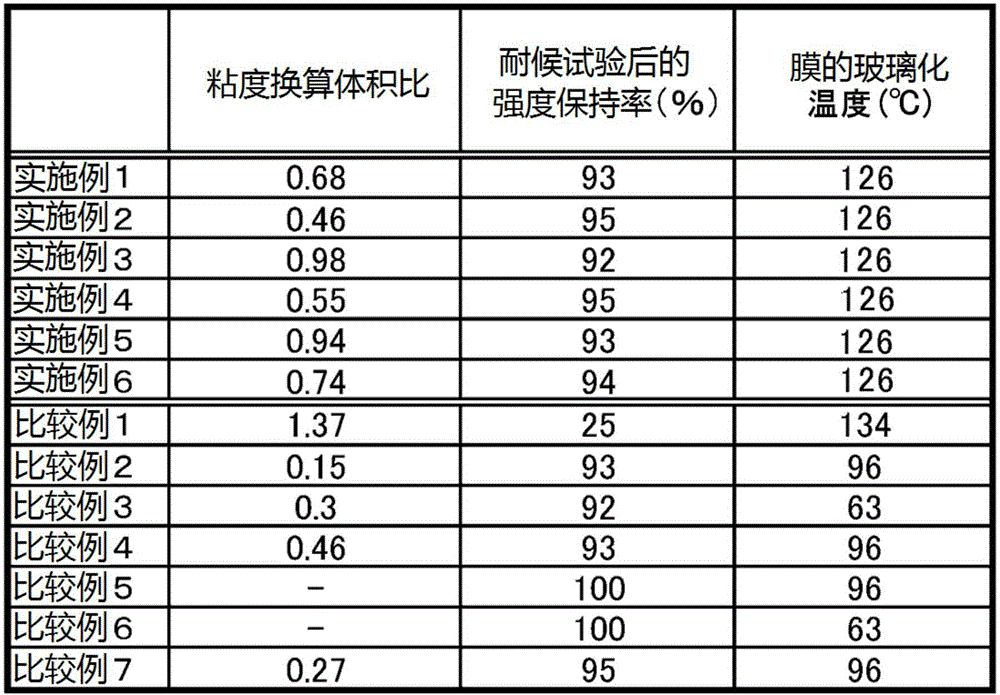

[0089] Hereinafter, although an Example is given and demonstrated to this invention, this invention is not limited to these Examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

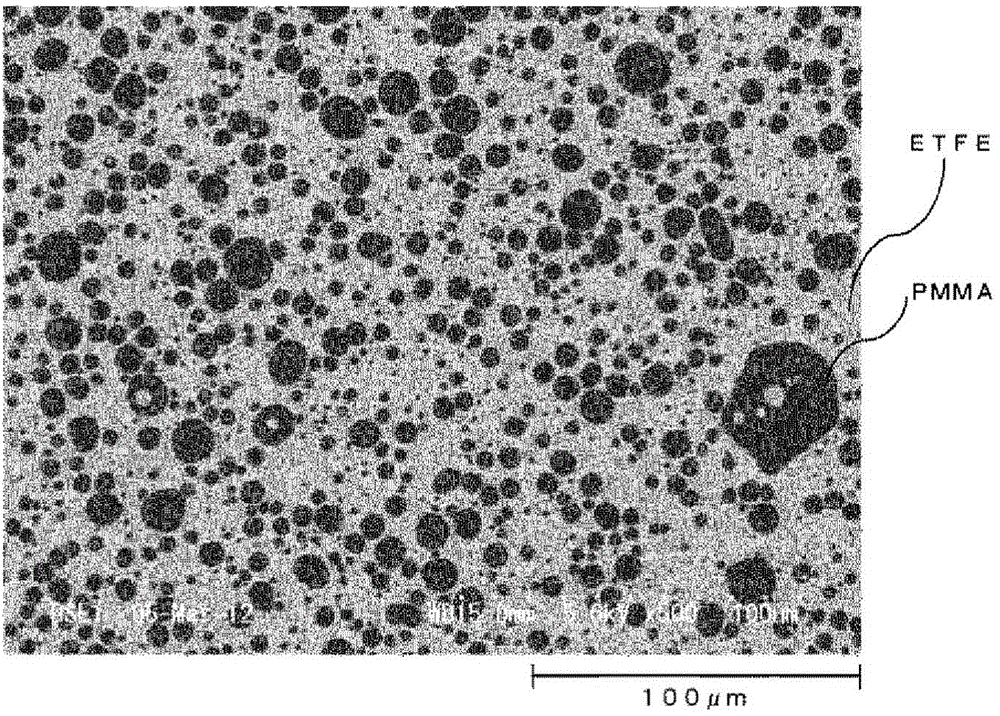

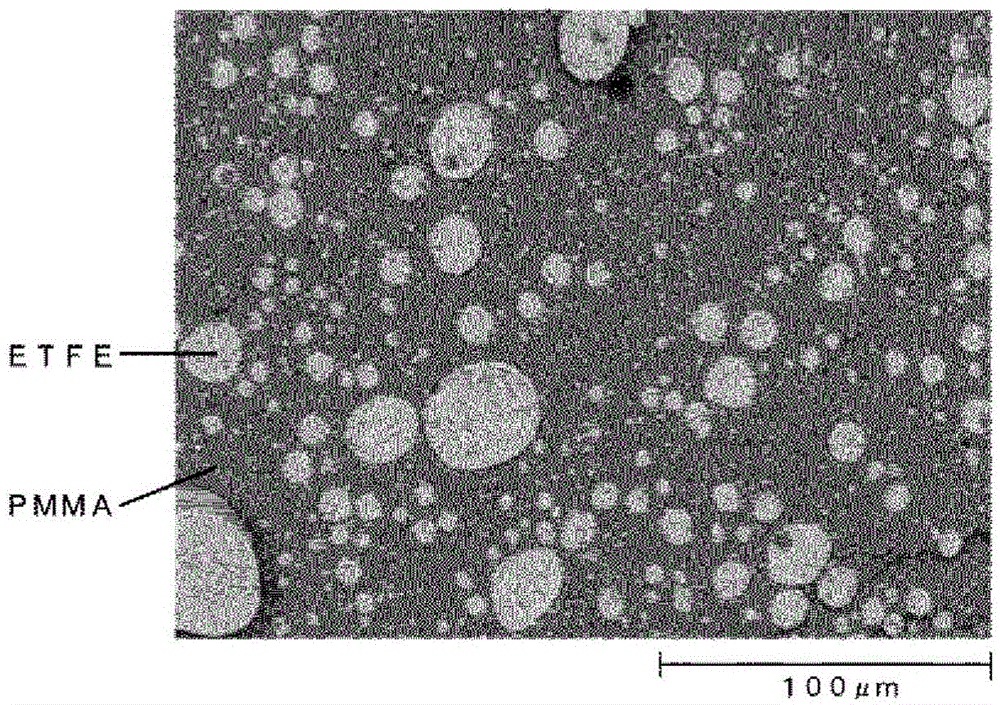

To provide a blended polymer containing an ethylene / tetrafluoroethylene copolymer, which is excellent in weather resistance and has a high thermal deformation temperature, a molded product such as a film thereof, a back sheet for a solar cell provided with such a film, etc., and a method for producing such a molded product. A blended polymer which comprises an ethylene / tetrafluoroethylene copolymer and a polymethyl methacrylate, wherein the mass ratio of the ethylene / tetrafluoroethylene copolymer to the total mass of the ethylene / tetrafluoroethylene copolymer and the polymethyl methacrylate, is from 50 to 75%, and which has a microphase-separated structure wherein the continuous phase is the ethylene / tetrafluoroethylene copolymer, and the dispersed phase is the polymethyl methacrylate.

Description

technical field [0001] The present invention relates to a mixed polymer containing ethylene / tetrafluoroethylene copolymer, a molded article of the mixed polymer, a back sheet for solar cells, and a method for producing the molded article. Background technique [0002] Fluoroplastics are used in various applications where general-purpose plastics cannot be used due to their excellent solvent resistance, low dielectric properties, low surface energy properties, non-adhesive properties, and weather resistance. Among them, ethylene / tetrafluoroethylene copolymer (hereinafter referred to as "ETFE") is a fluororesin excellent in heat resistance, flame retardancy, chemical resistance, weather resistance, low friction, low dielectric properties, etc., so It is used in a wide range of fields such as coating materials for heat-resistant electric wires, corrosion-resistant piping materials for chemical plants, materials for plastic greenhouses for agriculture, and release films for mold...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L27/18C08J5/18C08L23/08C08L33/12H01L31/049

CPCH01L31/0481C08J2327/18C08J2427/18C08J2333/12C08J2433/12H01L31/049C08J5/18C08L27/18C08L23/08C08L23/0892C08L33/12C08J2323/08C08J2423/08C08L2201/08Y02E10/50

Inventor 泽田敏亮小寺省吾中西智亮

Owner AGC INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com