Flame-retardant tube and heat-shrinkable tube made by using the same

A flame-retardant, tubular technology, applied in the field of tubes and heat-shrinkable tubes, can solve problems such as insufficient heat resistance, melting, and inability to maintain shape, and achieve the effect of excellent tensile properties and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

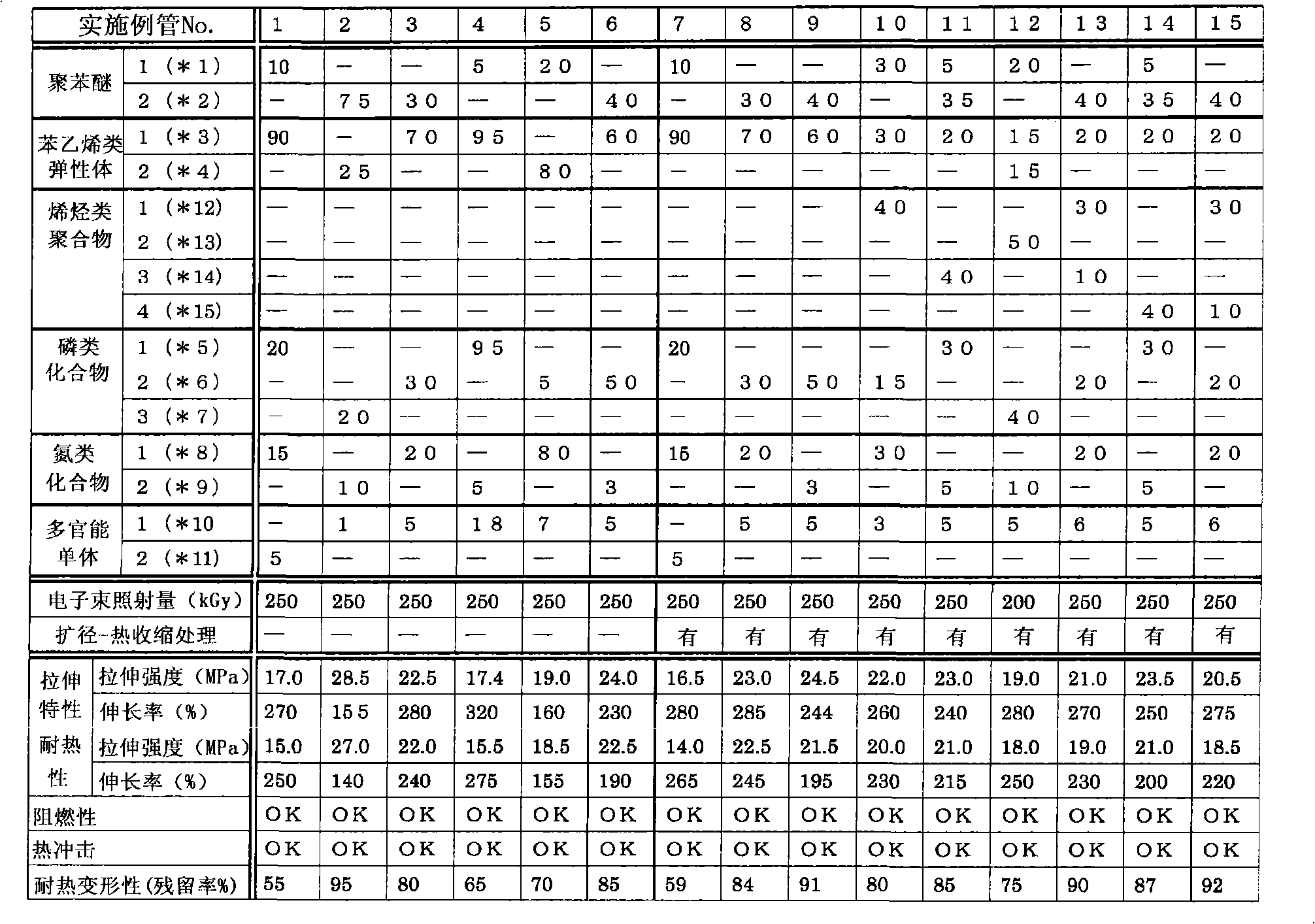

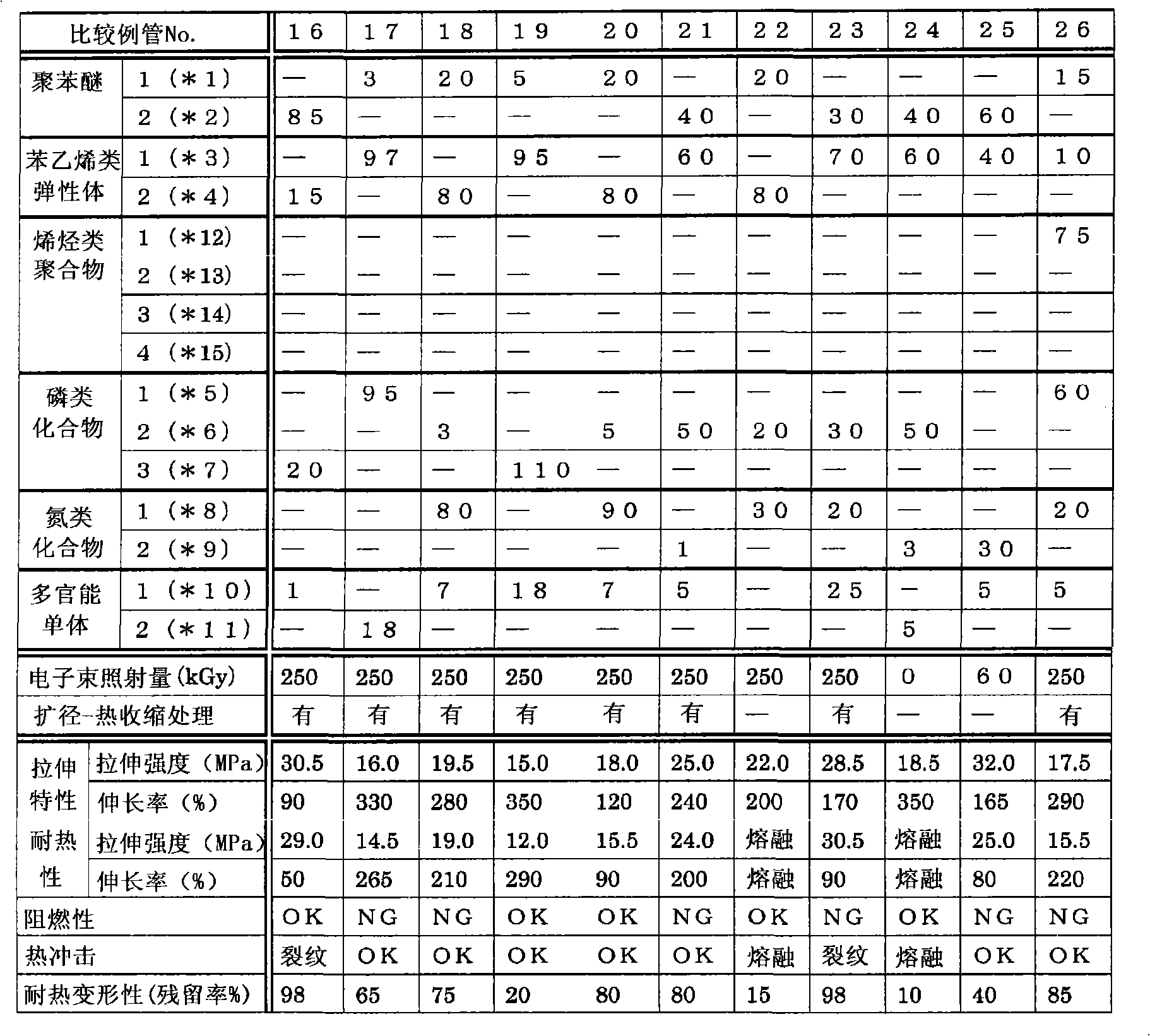

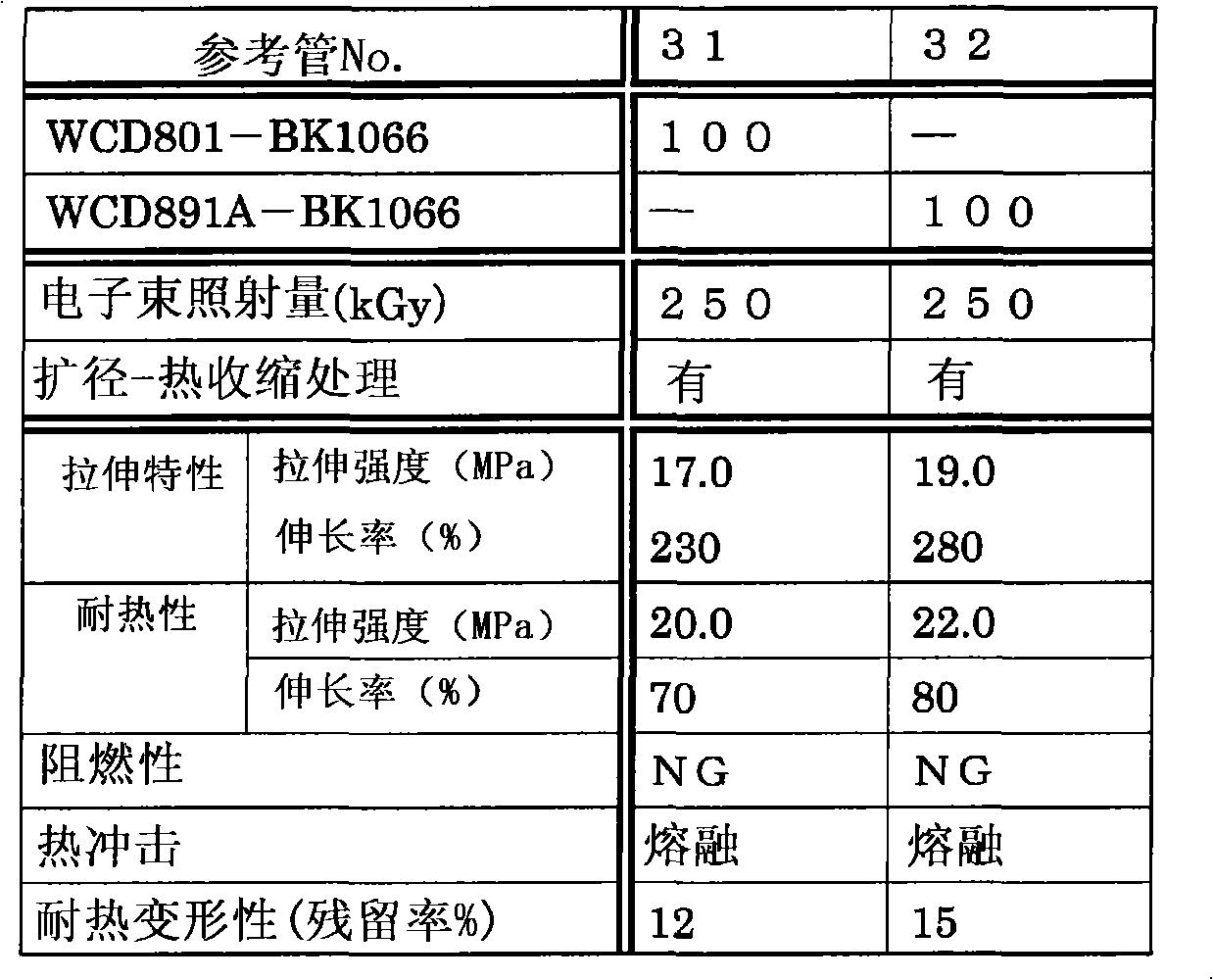

[0074] The best mode for carrying out the present invention will be described by way of examples. The examples do not limit the scope of the invention.

[0075] In addition, in the following examples, "parts" means "parts by mass" unless otherwise specified.

[0076] [measurement evaluation method]

[0077] First, the measurement and evaluation methods performed in the following examples will be described.

[0078] (1) Tensile properties

[0079] For the tube, perform a tensile test (tensile speed = 500 mm / min, distance between the marking lines = 20 mm), measure the tensile strength (MPa) and tensile elongation at break (%) for each 3 points of the sample, and obtain take their average. A tensile strength of 10.4 MPa or more and a tensile elongation at break of 150% or more are acceptable levels.

[0080] (2) Heat resistance

[0081] After the tube was left to stand for 168 hours (7 days) in a Jill aging incubator set at 158°C, the tensile test of (1) was performed. Wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com