Flexible flat cable

A flat cable and flexible technology, applied in the field of flexible flat cables, can solve the problems of corrosive gas generation, plasticizer precipitation, etc., and achieve the effect of excellent electrical insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] Using a twin-shaft mixer (45 mm φ, L / D = 42), melt-mix the components with the mixing formula shown in Example 1 in Table 1, melt-extrude in the form of strands, and then cool and cut the melted strands to make small pellets . In the resin composition described in Table 1, in 100 parts by weight of the resin component, 0.5 part by weight of oleic acid amide is mixed as a lubricant, and 1 part by weight of tetrakis [3-(3,5-bis tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester.

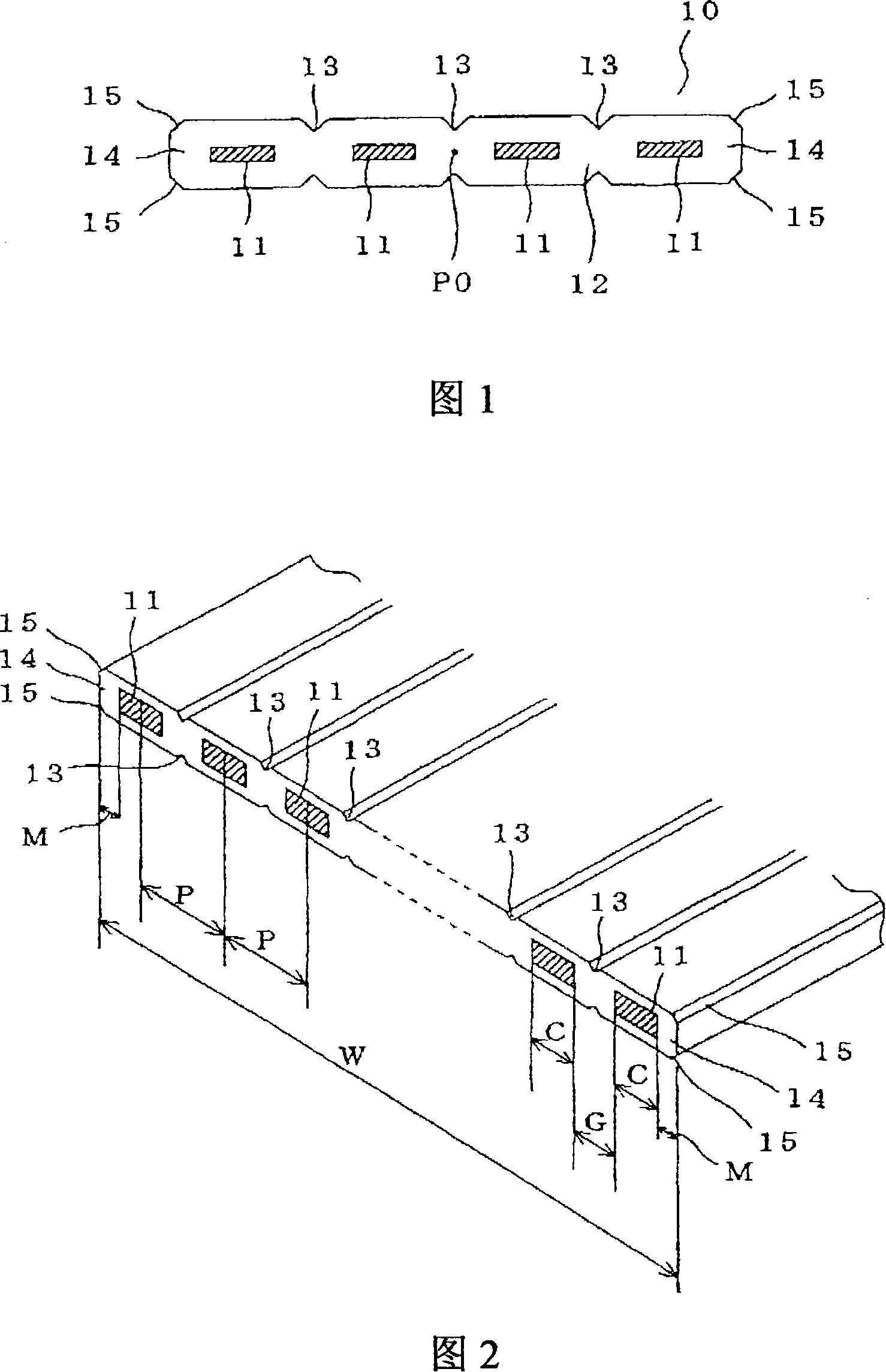

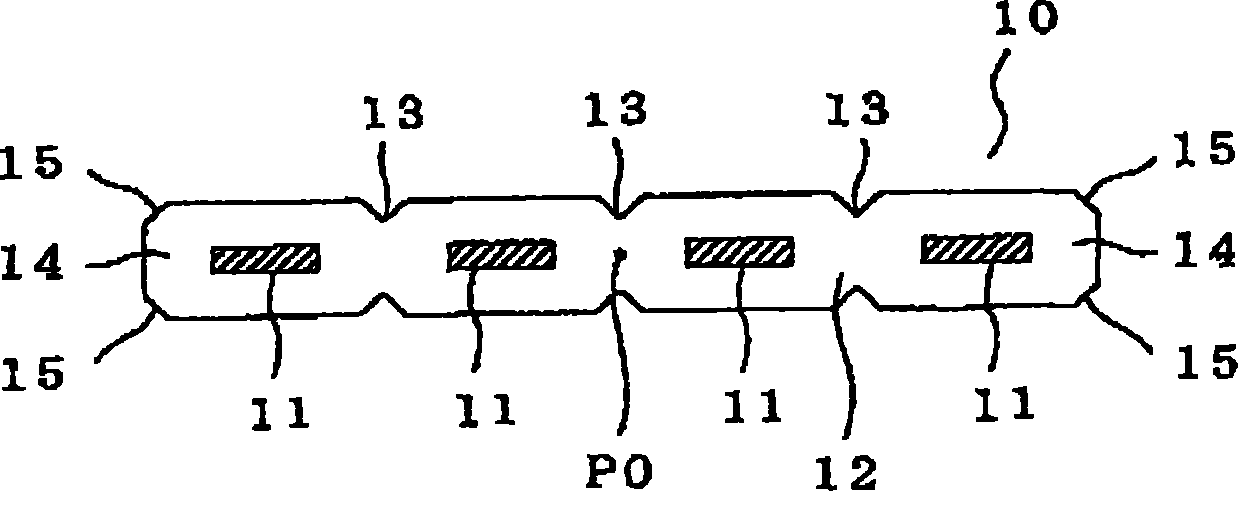

[0094] Eight flat conductors (flat tinned copper wires) with a width of 1.2 mm and a thickness of 0.15 mm are fed from the supply bobbin group to the concentrator, and arranged in parallel at a conductor pitch of 2.0 mm. Then, the eight flat conductors arranged in parallel were conveyed to a mold of a melt injection molding machine, and small pellets of the resin composition shown in Example 1 in Table 1 were supplied from the melt injection molding machine for insulating coating. T...

Embodiment 2~8

[0097] Each flexible flat cable was produced in the same manner as in Example 1, except that the mixing recipe of the flame-retardant resin composition in Example 1 was changed to that shown in Examples 2 to 8 in Table 1. The results are shown in Table 1.

[0098] Table 1

[0099] Example

1

2

3

4

5

6

7

8

TPU

(1) Adipate type TPU JIS hardness = A80

(2)PTMG type TPU JIS hardness=A80

(3) PC type TPU JIS hardness = A80

(4)PTMG type TPU JIS hardness=A85

(5) PC type TPU JIS hardness = A85

(6) Adipate type TPU JIS hardness = A85

(7) Adipate type TPU JIS hardness = A97

(8)PTMG type TPU JIS hardness=A98

EVA

(9) EVA-1 VA=90wt%

(10) EVA-2 VA=50wt%

(11) EVA-3 VA=41wt%

(12) Synthetic magnesium hydroxide

(13) Natural Magnesium Hydroxide

(14)Organic peroxide

(15) Cross-linking assistant

- ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com