Polycarbonate-based composite material and preparation method and application thereof

A polycarbonate and composite material technology, applied in the field of material modification, can solve the problems of plastic parts such as poor light yellowing resistance, decreased toughness, and poor heat deformation resistance, so as to avoid obvious light yellowing resistance Deterioration, reduction of usage, and improvement of low temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

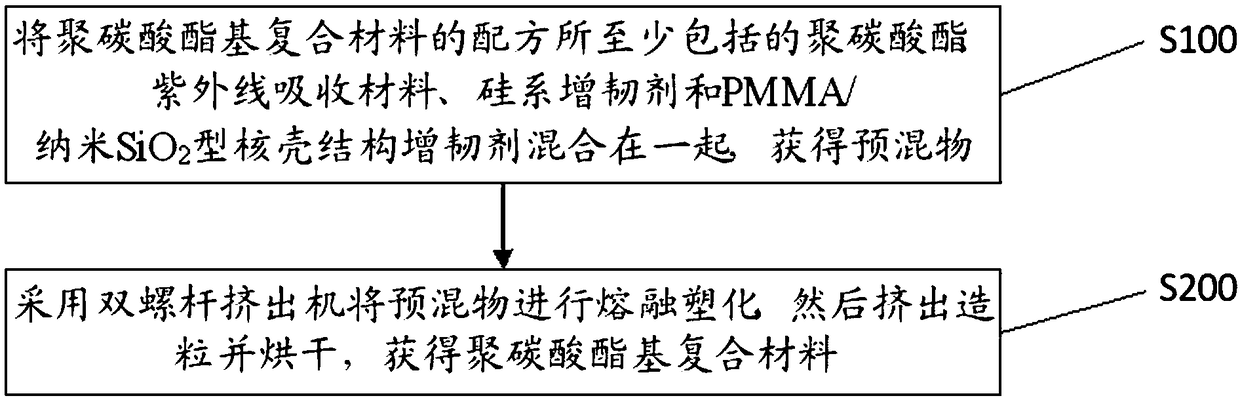

[0050] Such as figure 1 As shown, the embodiment of the present invention also provides a preparation method of a polycarbonate-based composite material, the preparation method of the polycarbonate-based composite material comprises:

[0051] The polycarbonate that the prescription of above-mentioned polycarbonate-based composite material at least includes, ultraviolet absorbing material, silicon series toughening agent and PMMA / nanometer SiO 2 The core-shell structure toughening agent is melted and plasticized to obtain polycarbonate-based composite materials.

[0052] Compared with the prior art, the beneficial effect of the preparation method of the polycarbonate-based composite material provided by the embodiment of the present invention is the same as that of the polycarbonate-based composite material provided by the above-mentioned embodiment, and will not be repeated here.

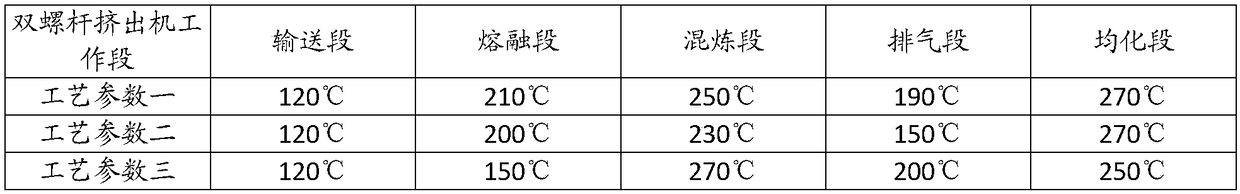

[0053] Specifically, such as figure 1 As shown, the formula of the polycarbonate-based composi...

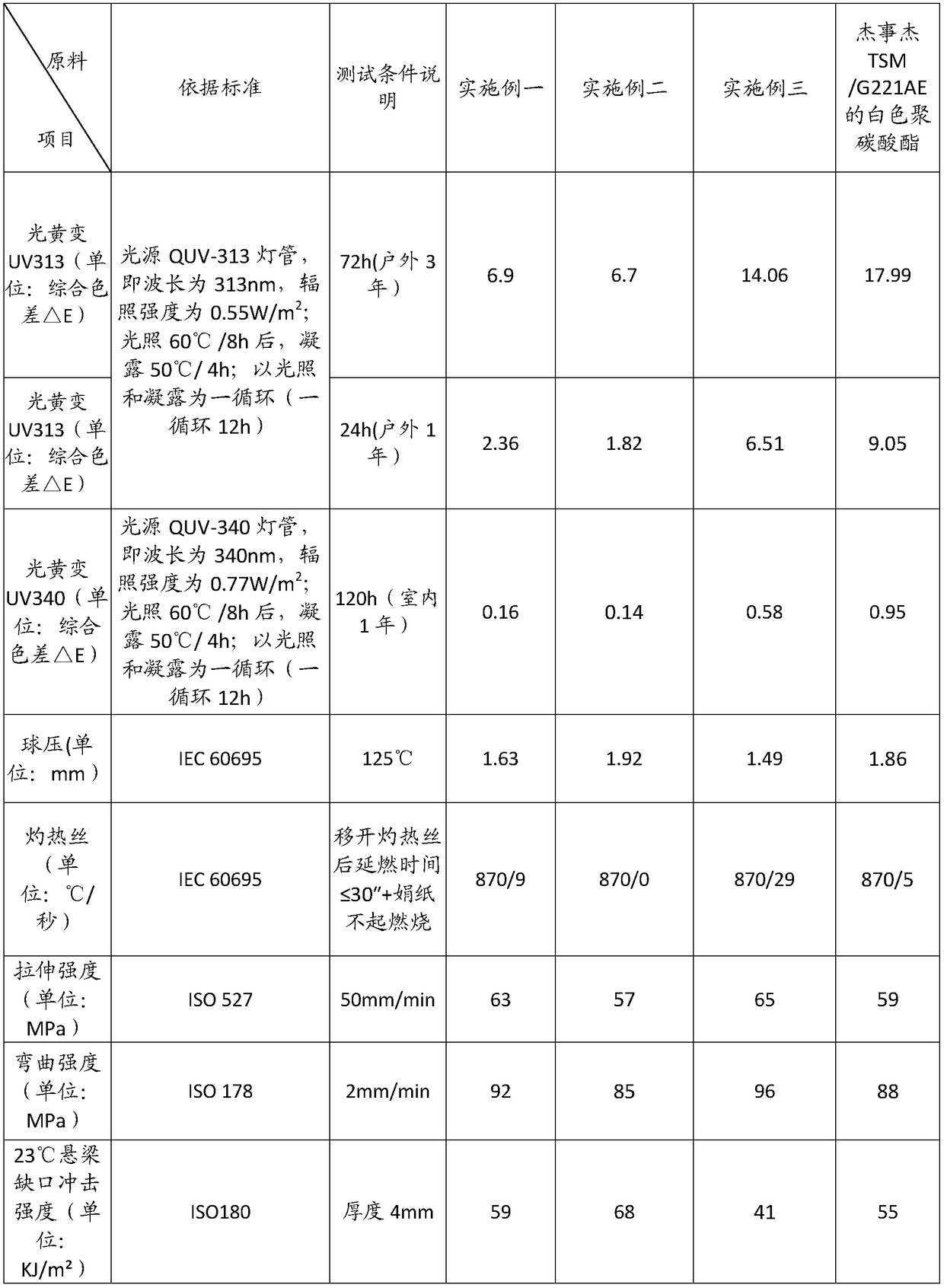

Embodiment 1

[0071] The formula used in the polycarbonate-based composite material provided in this embodiment includes polycarbonate (Covestro PC2800), silicon-propylene rubber toughening agent, PMMA / nanometer SiO 2 Type core-shell structure toughening agent, UV absorber TINUVIN 360, light stabilizer Uvinul 4050H, UV absorber TINUVIN 1600, FR-Si9805 organic silsesquioxane flame retardant, antioxidant 1010, antioxidant IRGANOX PS 802 The mass ratio of FD, titanium dioxide, EBS micronized wax lubricant P-400 and toner is 89.6:2:1.5:1:1.2:0.5:0.2:0.3:0.3:2:0.4:1. The PMMA / nano-SiO 2 The type core-shell structure toughening agent is obtained in the following way: 100g of alkylated nano-silica is added to 3000mL of 95% ethanol aqueous solution, and then 45g of polyvinylpyrrolidone is added thereto, and dispersed uniformly by ultrasonic, Get the premix. Put the premix into a sealed reaction kettle, and feed nitrogen into the reaction kettle. The reactor was heated with an oil bath and the pr...

Embodiment 2

[0074] The formula used in the polycarbonate-based composite material provided in this embodiment includes polycarbonate (Covestro PC2800), silicon-propylene rubber toughening agent, PMMA / nanometer SiO 2 Type core-shell structure toughening agent, UV absorber TINUVIN 360, light stabilizer Uvinul 4050H, UV absorber TINUVIN 1600, FR-Si9805 organic silsesquioxane flame retardant, antioxidant 1010, antioxidant IRGANOX PS 802 The mass ratio of FD, titanium dioxide, EBS micronized wax lubricant P-400 and toner is 80.5:4:2.5:2:2:1:2:0.8:0.8:2:0.4:1. The PMMA / nano-SiO 2 The type core-shell structure toughening agent is obtained in the following way: 100g of alkylated nano-silica is added to 3000mL of 95% ethanol aqueous solution, and then 45g of polyvinylpyrrolidone is added thereto, and dispersed uniformly by ultrasonic, Get the premix. Put the premix into a sealed reaction kettle, and feed nitrogen into the reaction kettle. The reactor was heated with an oil bath and the premix w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com