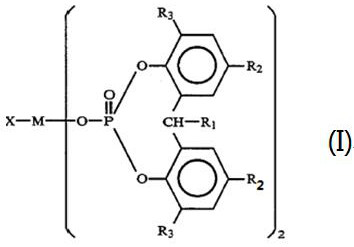

A kind of toughened polypropylene material and preparation method thereof

A polypropylene material and homopolypropylene technology are applied in the field of toughened polypropylene materials and their preparation, which can solve the problem of high equipment investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

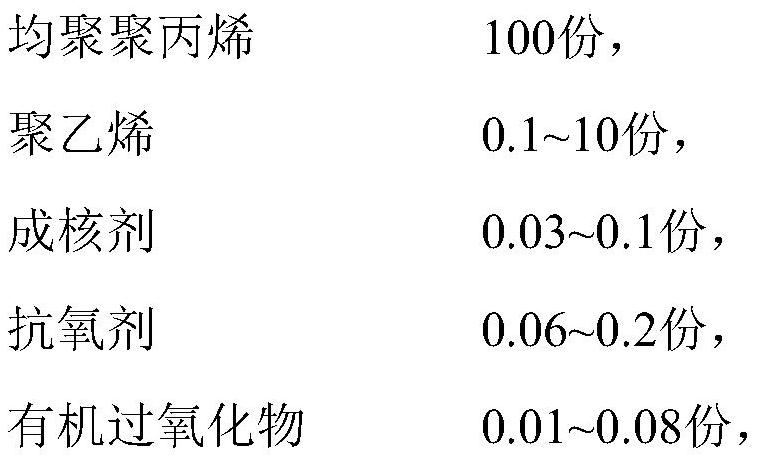

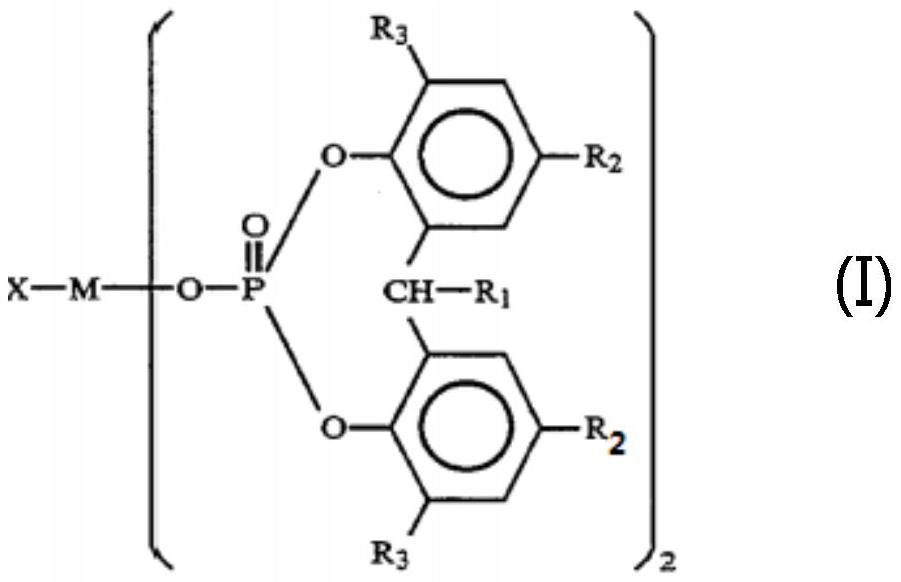

[0026] The polypropylene material is prepared according to the following components by weight: 100 parts of homopolypropylene (prepared by hydrogen adjustment method, MFR is 15g / 10min), 1 part of polyethylene (LLDPE, commercially available grade is 7042), nucleating agent NA -21 0.04 part, main antioxidant 1010 (chemical name tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester) 0.06 part, auxiliary antioxidant 168 (chemical Named as tris[2.4-di-tert-butylphenyl]phosphite 168) 0.12 parts, organic peroxide 101 (chemical name is 2,5-dimethyl-2,5-bis(tert-butyl peroxy ) hexane) 0.04 parts.

Embodiment 2

[0028]The polypropylene material is prepared according to the following components by weight: 100 parts of homopolypropylene (prepared by hydrogen adjustment method, MFR is 15g / 10min), 1 part of polyethylene (LLDPE, commercially available grade is 7042), nucleating agent NA -21 0.08 part, 0.06 part of primary antioxidant 1010 (chemical name tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester), secondary antioxidant 168 (chemical Named as tris[2.4-di-tert-butylphenyl]phosphite 168) 0.12 parts, organic peroxide 101 (chemical name is 2,5-dimethyl-2,5-bis(tert-butyl peroxy ) hexane) 0.04 parts.

Embodiment 3

[0030] The polypropylene material is prepared according to the following components by weight: 100 parts of homopolypropylene (prepared by hydrogen adjustment method, MFR is 15g / 10min), 1 part of polyethylene (LLDPE, commercially available grade is 7042), nucleating agent NA -21 0.11 part, main antioxidant 1010 (chemical name tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester) 0.06 part, secondary antioxidant 168 (chemical Named as tris[2.4-di-tert-butylphenyl]phosphite 168) 0.12 parts, organic peroxide 101 (chemical name is 2,5-dimethyl-2,5-bis(tert-butyl peroxy ) hexane) 0.04 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com