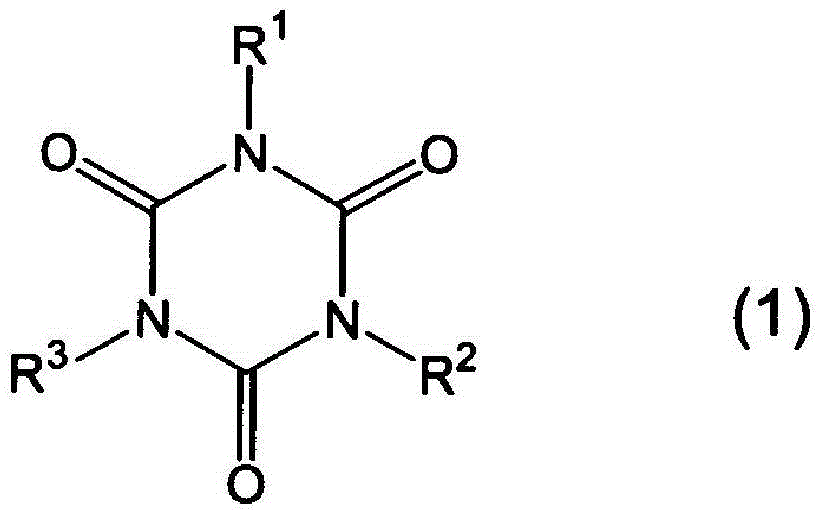

Electron beam curable resin composition, reflector resin frame, reflector, semiconductor light-emitting device, and molded article production method

A resin composition, electron beam curing technology, applied in the direction of electric solid devices, semiconductor devices, circuits, etc., can solve the problems of lower reflectivity, shorter life of LED components, lower brightness, etc., and achieve the effect of excellent thermal deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~16、 comparative example 1~3

[0149] As shown in the following Tables 2-1 to 2-4, various materials were blended and kneaded to obtain a resin composition.

[0150]It should be noted that, regarding the resin composition, various materials were blended using an extruder (Nippon Placon Co., Ltd. MAX30: die diameter 3.0 mm) and a granulator (Tongyo Seiki Manufacturing Co., Ltd. MPETC1). carried out to obtain a resin composition.

[0151] These compositions were press-molded under the conditions of 250° C., 30 seconds, and 20 MPa to a size of 750 mm×750 mm×thickness 0.2 mm to produce a molded article (1).

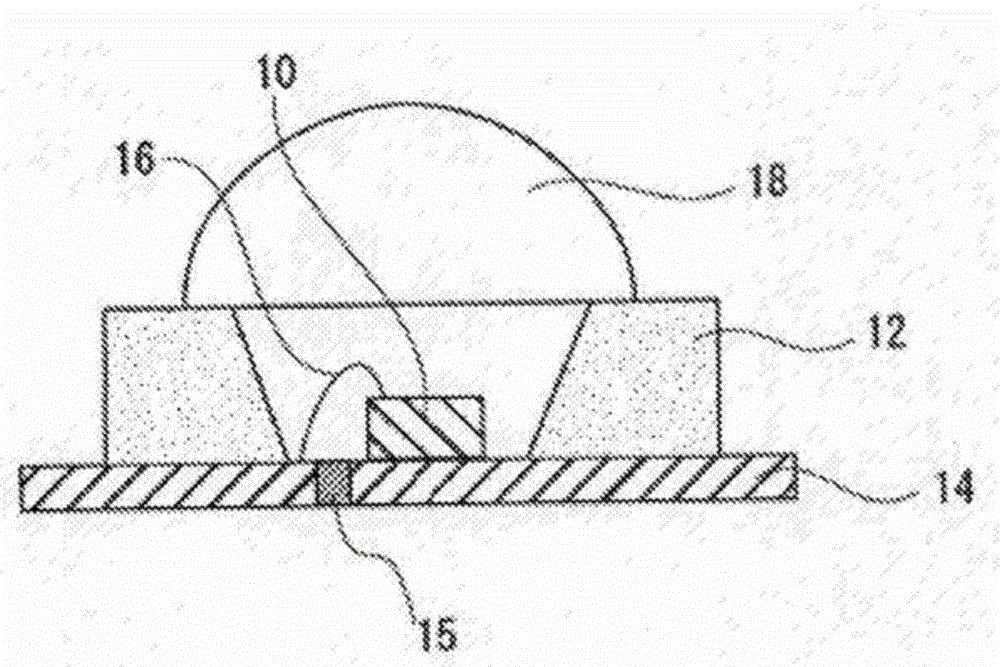

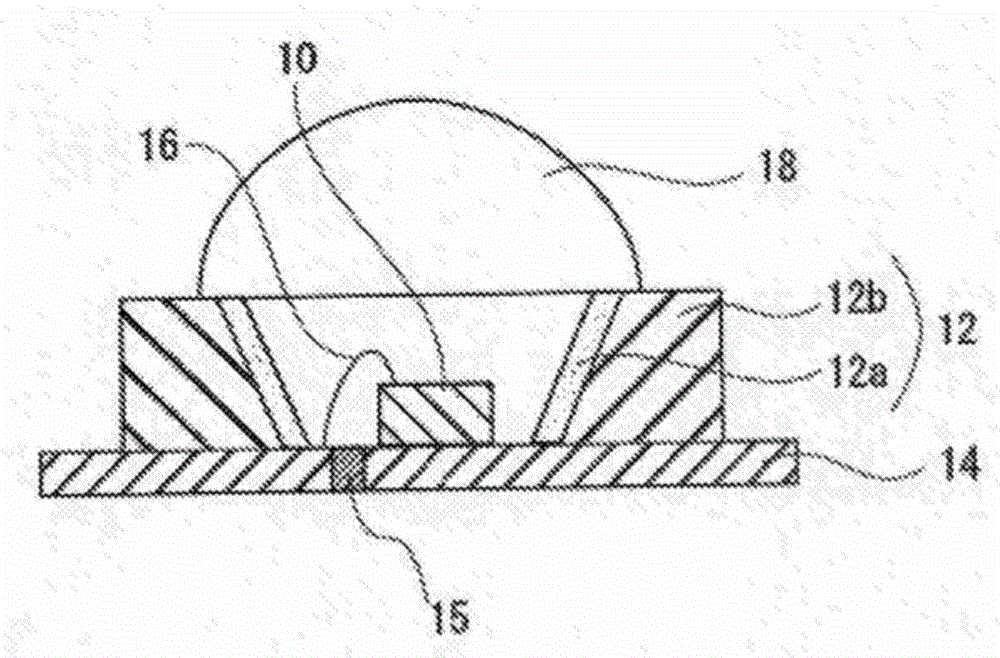

[0152] In addition, the above-obtained resin composition was placed on a silver-plated frame (thickness: 250 μm) using an injection molding machine Sodick TR40ERSodick (pre-molding type) so that thickness: 700 μm, external dimensions: 35mm×35mm, opening: 2.9mm×2.9 The molding was carried out in mm to obtain a resin frame molding (2) for reflectors. The conditions of the injection molding machine are as f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com