High-strength stainless steel wire excellent in thermal deformation resistance, high-strength spring, and manufacturing method thereof

A technology of heat deformation resistance and manufacturing method, which is applied in the direction of manufacturing tools, low internal friction springs, springs/shock absorbers, etc., to promote the formation of fine compounds, high strength heat deformation resistance, and excellent heat deformation resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0126] "Manufacturing of Stainless Steel Wire"

[0127] Table 1 and Table 2 show the chemical components of the stainless steels used in the examples, and also describe the comparative steels. In both Tables 1 and 2, numerical values outside the range specified in this embodiment are underlined.

[0128]

[0129]

[0130] The steels with these chemical compositions are melted in a vacuum melting furnace, cast into a billet of φ178mm, and the billet is made into a bar steel of φ62mm by hot forging. Next, it was heated to 1250° C. and extruded using a hot extrusion simulator to produce a wire rod with a diameter of 10.7 mm. After that, solution treatment and pickling are performed, and the wire is drawn to φ5.5mm to make a wire rod.

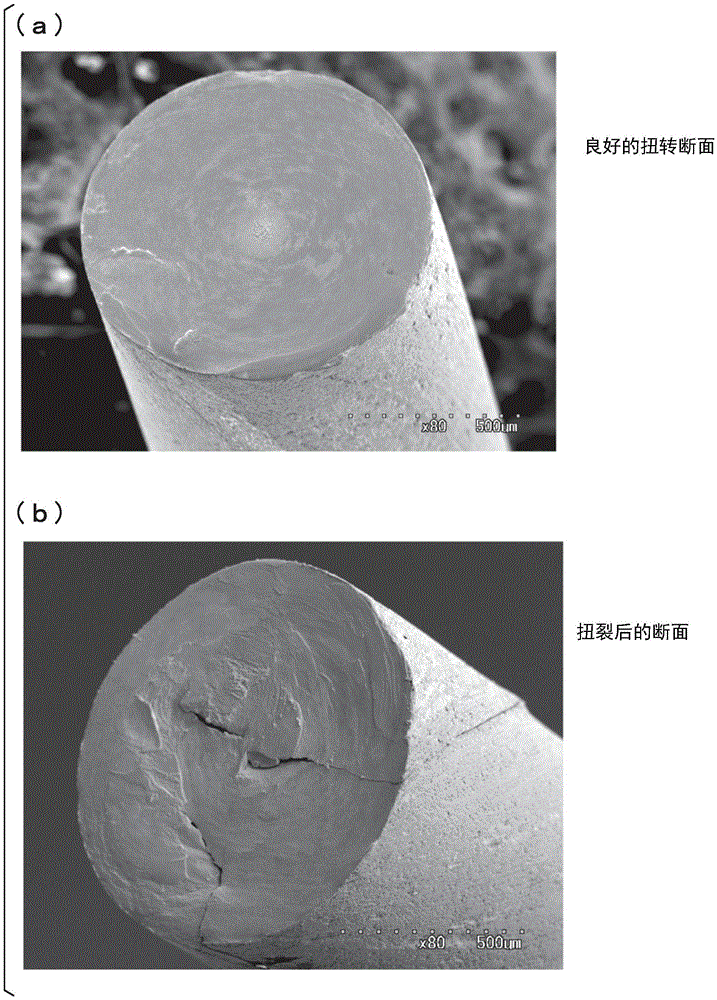

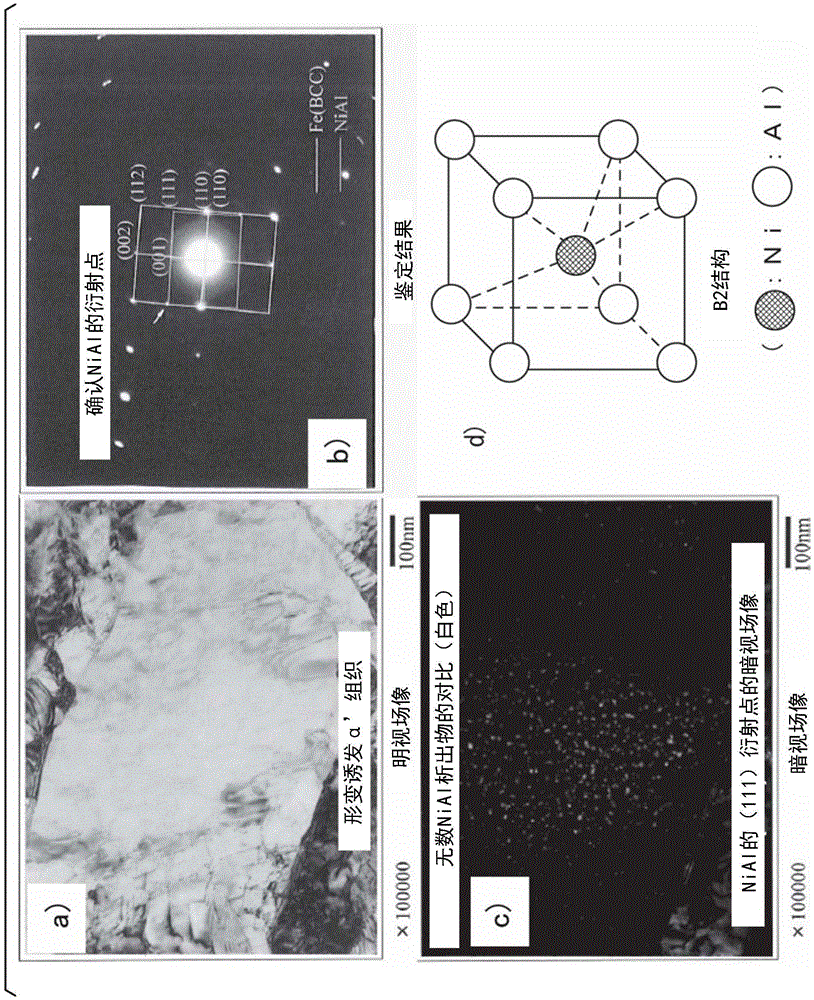

[0131]Then, this was processed into a soft wire having a wire diameter of 2.2 mm while repeatedly performing cold drawing processing and solution heat treatment as a raw material. Next, a hard thin wire (drawn wire rod) having a wire dia...

Embodiment 2

[0140] "Verification of aging characteristics"

[0141] Next, in order to evaluate the change in properties caused by the aging heat treatment of the stainless steel wires (drawn wire rods) of Example 1, each stainless steel wire (drawn wire rod) in Example 1 after the final wire drawing process was cut into A sample was obtained with a length of 150 mm. Then, aging heat treatment was performed on the sample at 500° C. for 30 minutes. The aging heat treatment factor represented by the formula (3) is 612.

[0142] Then, the tensile strength, yield strength, yield ratio, number of torsion values, and rigid modulus of the stainless steel wire (drawn wire, aging heat-treated material) after the aging heat treatment were evaluated. The results are shown in Table 5 and Table 6. In addition, the rigidity modulus was evaluated using the torsion pendulum method.

[0143] table 5

[0144]

[0145] Table 6

[0146]

[0147] Underline: outside the scope of this embodiment

[...

Embodiment 3

[0151] "Verification of Spring Products"

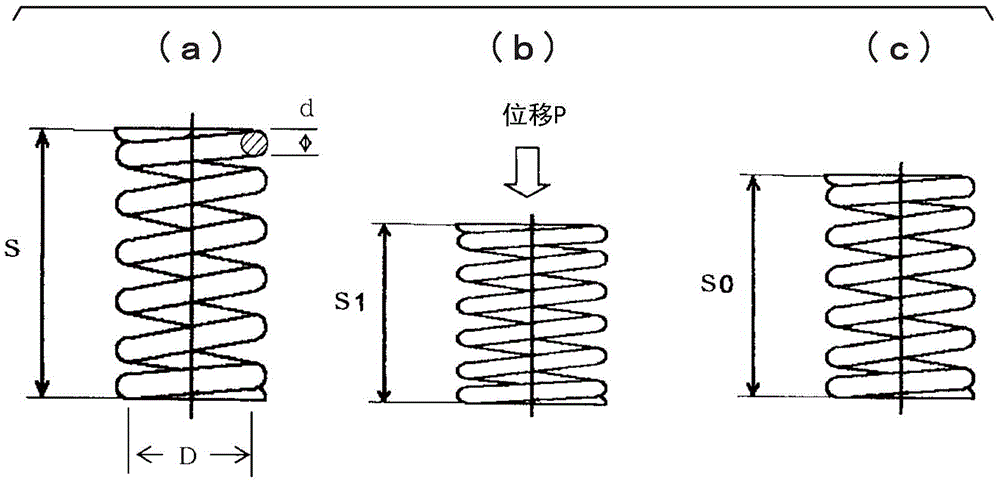

[0152] Then, in order to further verify the effect of Example 2, each stainless steel wire (drawing wire) before the aging heat treatment is implemented to be coiled, forming a coil with an average diameter of 7mm, an effective number of coils of 4.5 turns, and a spring free length of 25mm, compressed coil spring with an expanded length of 100mm. Next, aging heat treatment was performed at 500° C. for 30 minutes. Then, the heat deformation resistance of the actual spring product was evaluated. The heat deformation resistance (residual shear strain ε) was measured by the method described in the above-mentioned "Manufacturing method of a spring product". Specifically, it was held at 200° C. for 96 hours while maintaining a state where a compressive stress of 600 MPa was applied. Then, the residual shear strain ε was calculated using formula (7).

[0153] The obtained results are shown in Table 5 and Table 6. It was confirmed that t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com