Flexing-resistant multi-core control cable

A technology of control cable and flex resistance, which is applied in the fields of flex-resistant multi-core control cables, electric welding machine cables, and multi-core control cables, and can solve the problems of weather resistance, oil resistance or solvent resistance, heat deformation resistance, and use environment Problems such as complex conditions, wear resistance, and small adhesion can be solved to achieve the effect of poor softness, simple structure, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

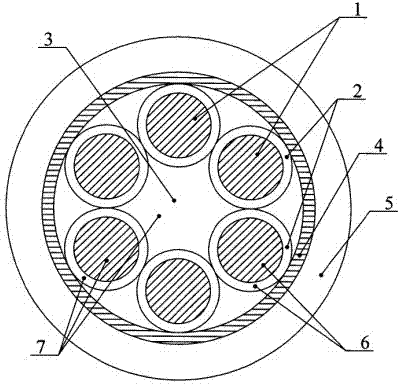

[0030] Such as figure 1 As shown, a flex-resistant multi-core control cable includes a copper conductor 1 and an insulating layer 2 , and also includes a core wire 6 composed of the copper conductor 1 and the insulating layer 2 . A filler 3 is arranged in the middle of a plurality of core wires arranged in a single layer, and the plurality of core wires and the filler 3 are stranded to form a cable core 7, and a wrapping layer 4 is arranged on the outside of the cable core 7, and an outer sheath 5 is extruded around the wrapping layer 4.

[0031] Among them: the insulating layer 2 is a low shrinkage polyvinyl chloride insulating layer; the filling 3 is a soft filling material, preferably hemp rope; the wrapping layer 4 is a non-woven wrapping layer; the outer sheath 5 is based on ethylene-propylene Oil resistant radiation crosslinked sheath.

[0032] The original single core is improved to a multi-core structure arranged in a single layer. Under the condition of ensuring the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com