Process and equipment for preparing nanoparticle-reinforced metal matrix composite material

A technology of nano-particles and composite materials, applied in mechanical equipment, heat exchange equipment, rotors, etc., can solve the problems of three-dimensional size nano-materials that need to be further developed, pollution, and the inability to strictly control the reaction process and product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

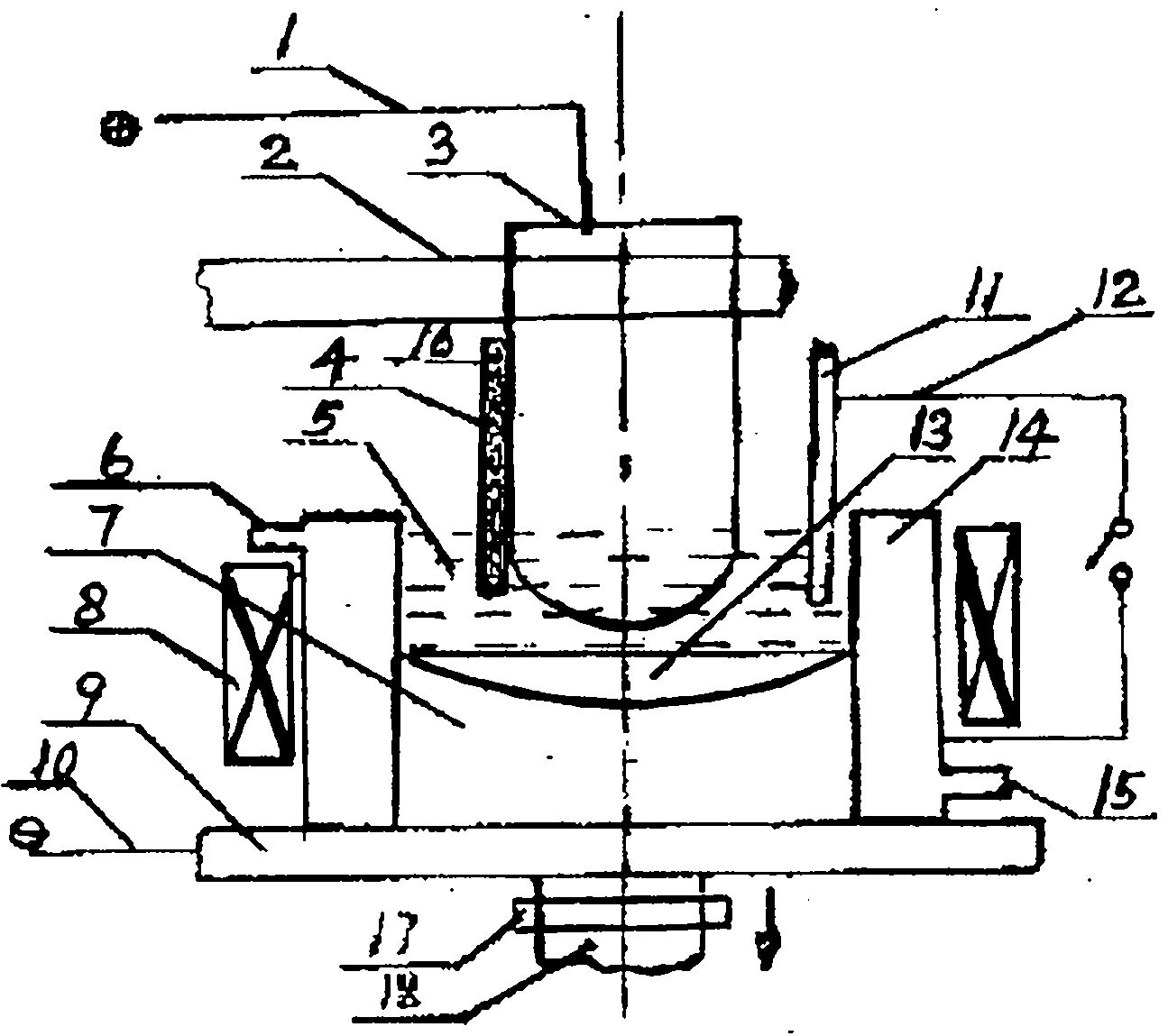

[0063] Example 1: In Fig. 1, the equipment consists of two systems of nanoparticle synthesis, diffusion, mixing equipment and casting molding equipment, wherein the nanoparticle synthesis, diffusion, and mixing equipment adopts high-energy stirring ball mill standard equipment, and the positive electrode power supply of casting molding equipment 1 , electrode holder 2, consumable electrode 3, low-carbon steel thin-wall sealed steel pipe 4 with pre-mixed nano-powder 16 or cored alloy wire with nano-particle pre-mixed powder 4, slag pool 5, outlet pipe 6. Nanoparticle-reinforced metal matrix composite material 7, electromagnetic stirrer 8, bottom water tank 9, negative power supply 10, high-energy pulse electrode 11, high-energy pulse power supply 12, metal molten pool 13, water-cooled crystallizer 14, water inlet pipe 15, Nanoparticle premixed powder 16, ultrasonic vibrator 17, ingot pumping device 18 are composed.

[0064] 1. Preparation of nanocrystalline particle liquid mixe...

Embodiment 2

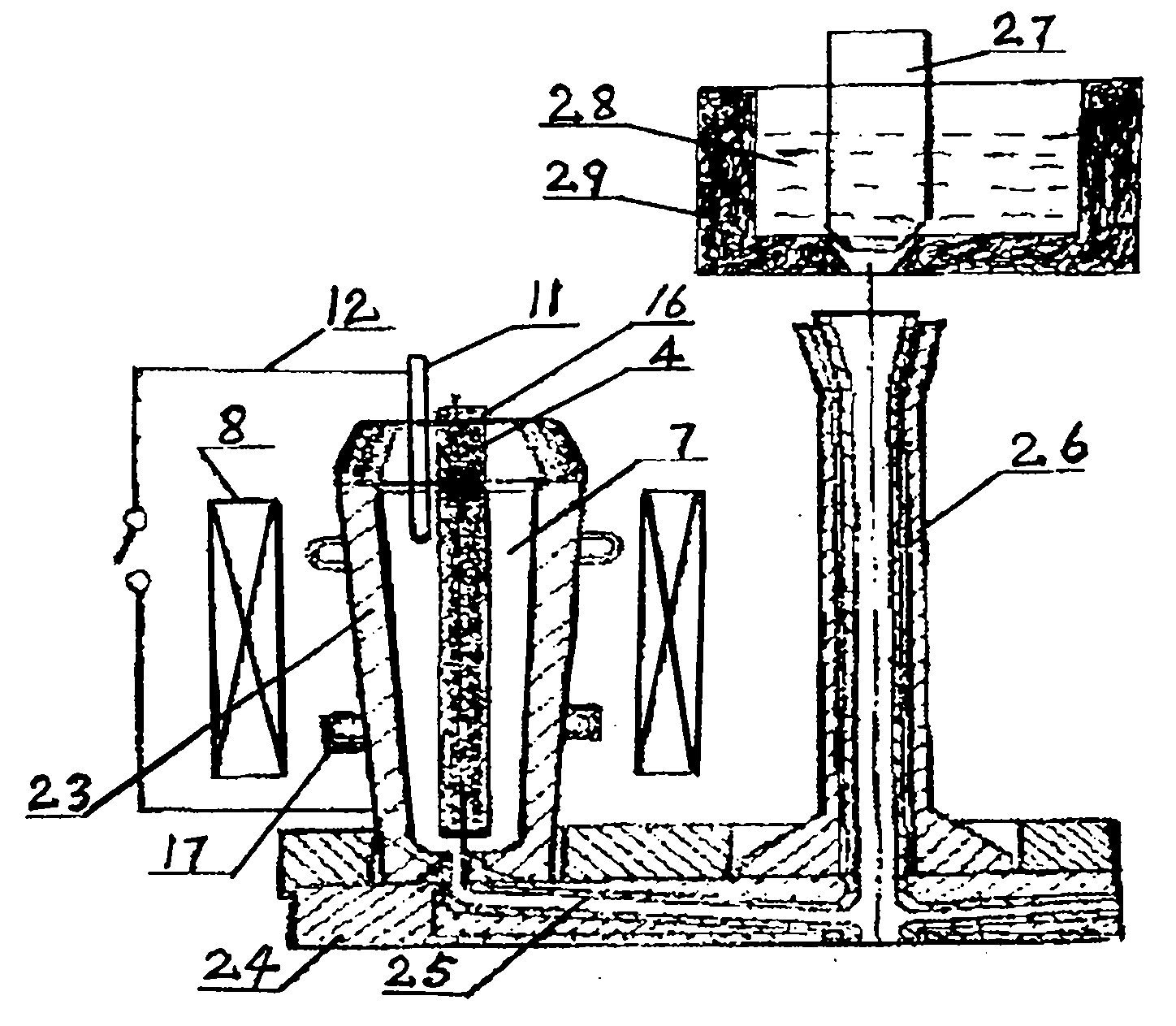

[0068] Embodiment 2: In Fig. 2, the casting molding equipment is pouring casting molding equipment system, and the casting molding equipment consists of a metal casting mold 23 installed on the pouring base plate 24, and an electromagnetic stirrer 8 is installed outside the casting mold 23. The upper or lower part of the type 23 is equipped with an ultrasonic vibrator 17, and high-energy pulse electrodes 11 and connection power sources 12 are respectively installed on both sides of the upper part in the mold 23, and an intermediate injection pipe 26 is installed next to the pouring bottom plate 24, and the intermediate injection pipe The center of 26 has pouring runner 25 and links to each other with the hole at the bottom of casting mold 23, is connected with pouring ladle 29 on the top of middle injection pipe 26, is filled with base metal liquid 28 in pouring ladle 29, is installed in pouring ladle 29 Stopper rod equipment 27 forms, and mold material is ferrous metal materia...

Embodiment 3

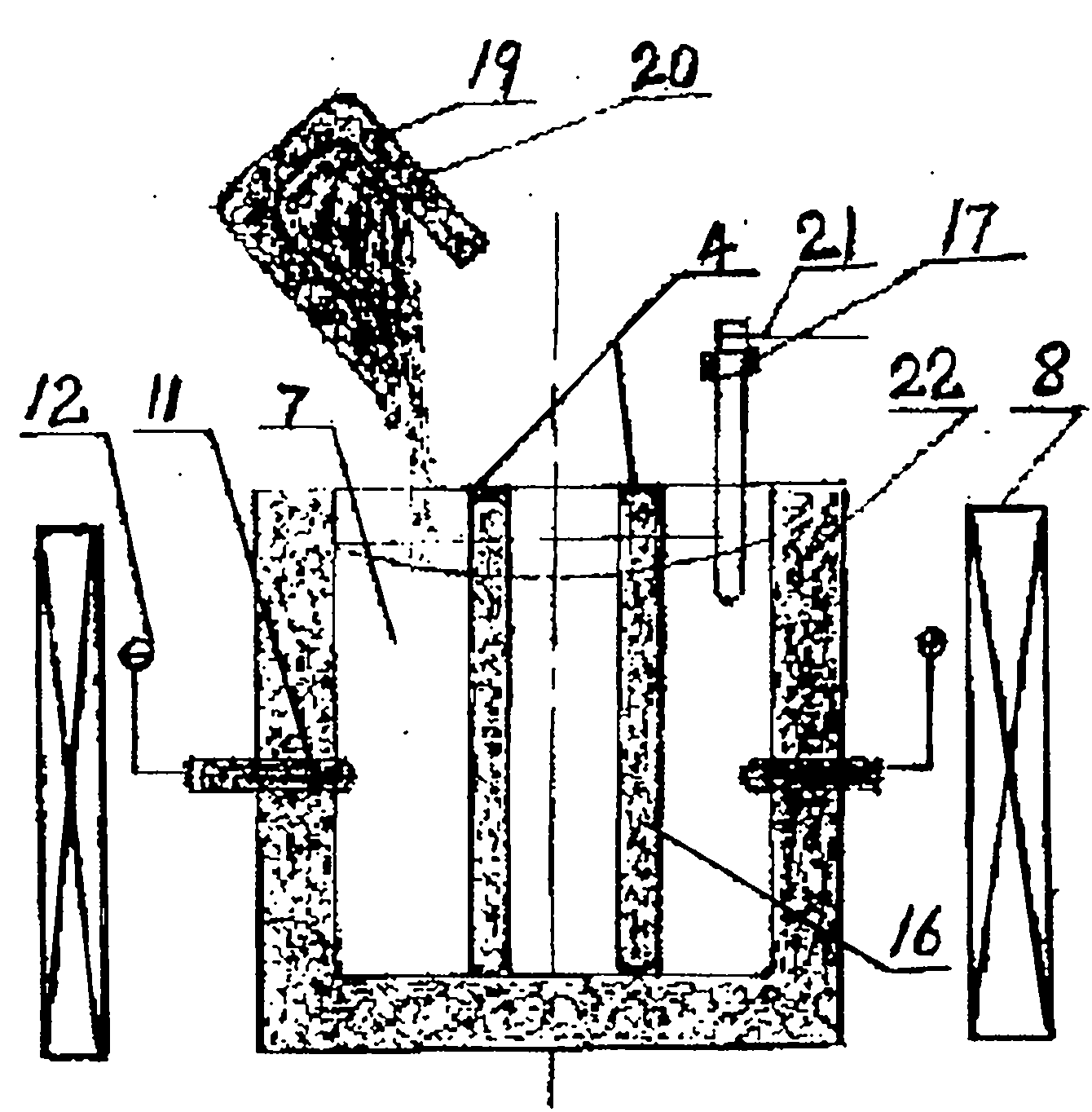

[0071] Embodiment 3: In Fig. 3, the difference from Embodiment 2 is that the pouring molding equipment is composed of a mold 22, an electromagnetic stirrer 8 is installed outside the mold 22, and an ultrasonic vibrator 17 is installed on the top of the mold 22 , ultrasonic vibrator power supply 21, high-energy pulse electrodes 11 and connection power supply 12 are respectively installed on both sides of the middle part in the mold 22, and a casting ladle 19 is arranged on the top of the casting mold 22, and the matrix molten metal is contained in the pouring ladle 19 20. The material of casting mold 22 is made of refractory material or ferrous metal material.

[0072] When the work starts, one or more low-carbon steel thin-walled sealed steel pipes 4 containing nanoparticle premixed powder 16 or the pressed block 4 of nanoparticle premixed powder 16 that have been prepared are fixed in the center of the mold 22, Or in the casting mold 22 according to a certain interval distan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com