Heat-resisting thermoplastic halogen-free low-smoke flame retardant polyolefin plastic for wire and cable

A wire and cable, low-smoke flame-retardant technology, applied in the direction of insulated cables, plastic/resin/wax insulators, cables, etc., can solve problems such as cracking, unavoidable thermal stress cracking, and biased performance, and achieve reasonable selection. Effects of avoiding thermal stress cracking, improving flame retardancy and oxygen index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

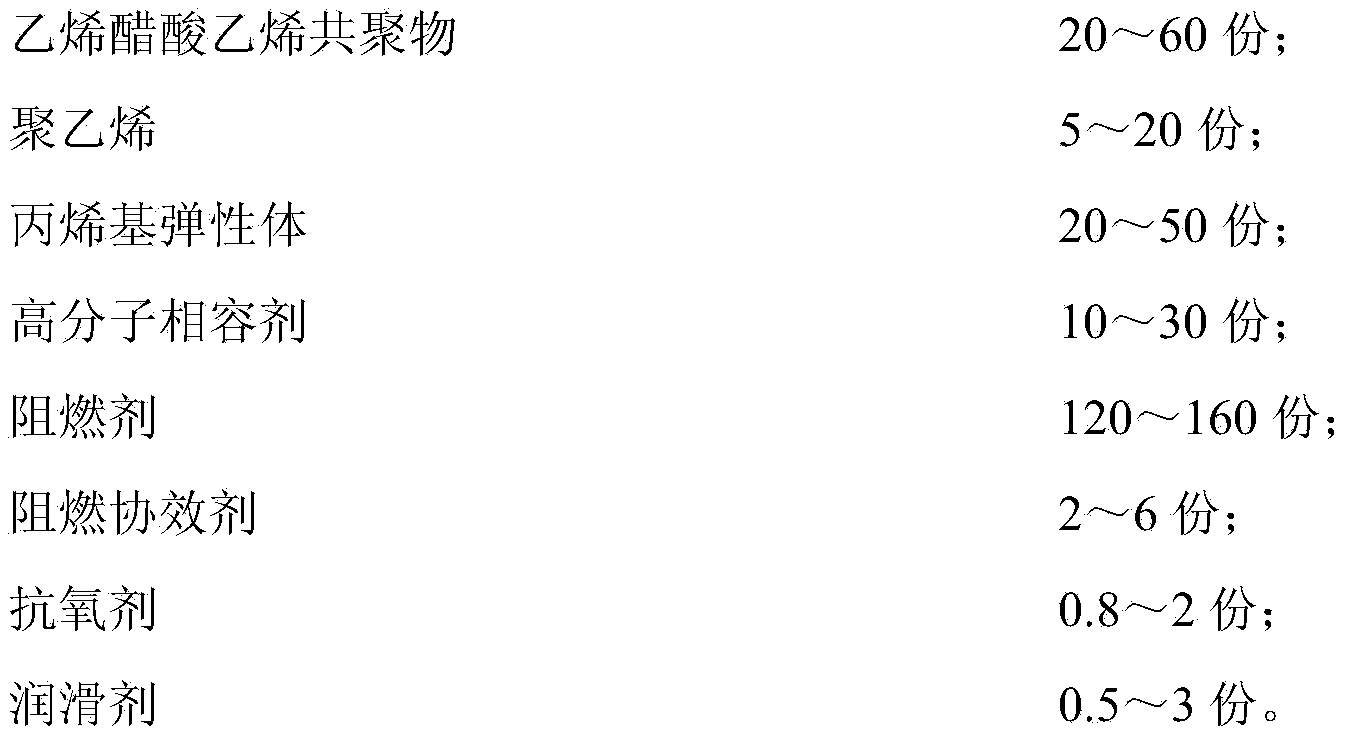

Method used

Image

Examples

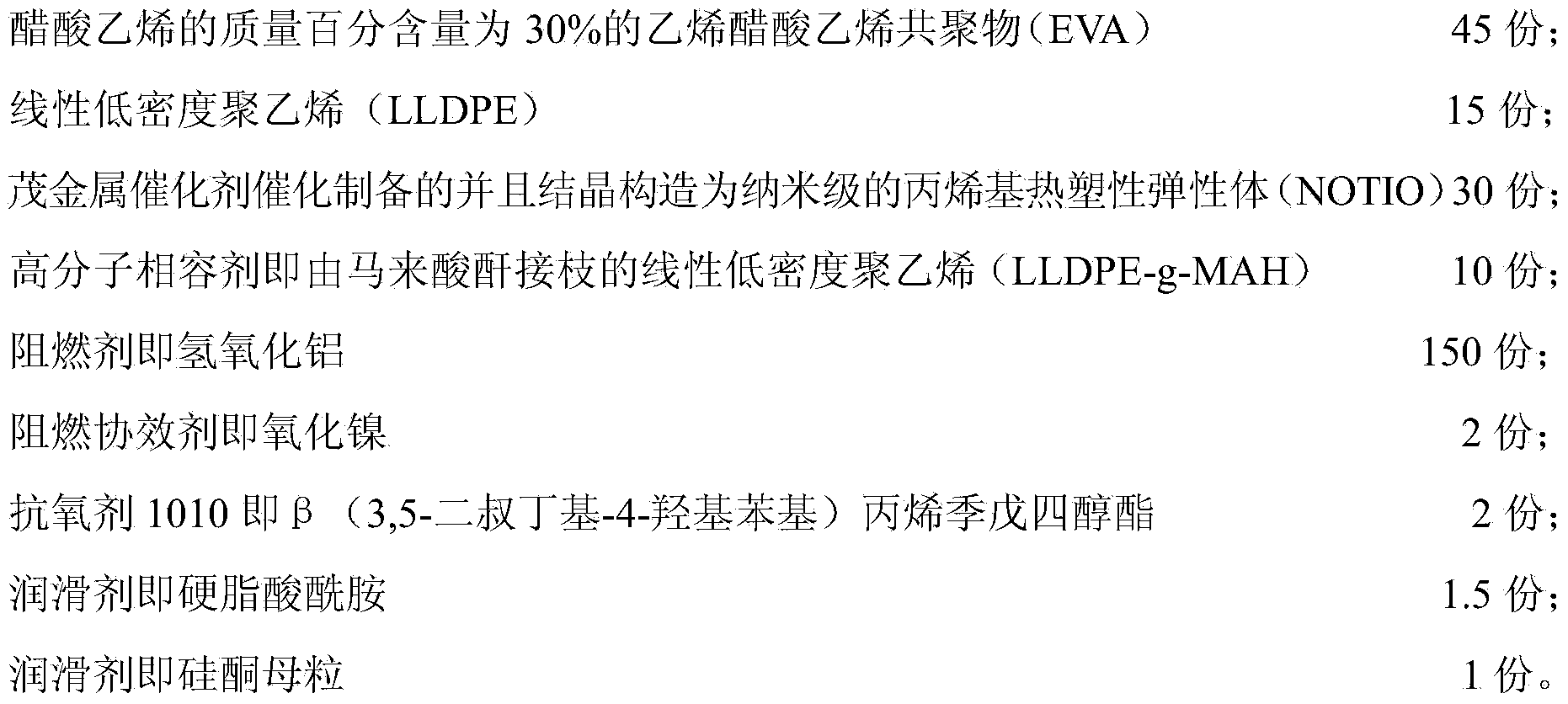

Embodiment 1

[0024]

[0025] The NOTIO described in this example is produced by Mitsui Chemicals, Japan, and the crystalline part of the elastomer is dispersed at the nanometer level to control the structure of the non-crystalline part.

[0026] When preparing, first add the above-mentioned components into a high-speed kneader and mix them evenly, then transfer them to a twin-screw extruder for melt extrusion, cool and pelletize, and obtain heat-resistant thermoplastic halogen-free low-smoke flame-retardant polyolefin plastics for wire and cable . Or put it into the internal mixer for internal mixing, and then transfer to the twin-screw extruder for melt extrusion. The plastic components are mixed, plasticized and granulated to make heat-resistant thermoplastic halogen-free flame-retardant polyolefin plastic particles.

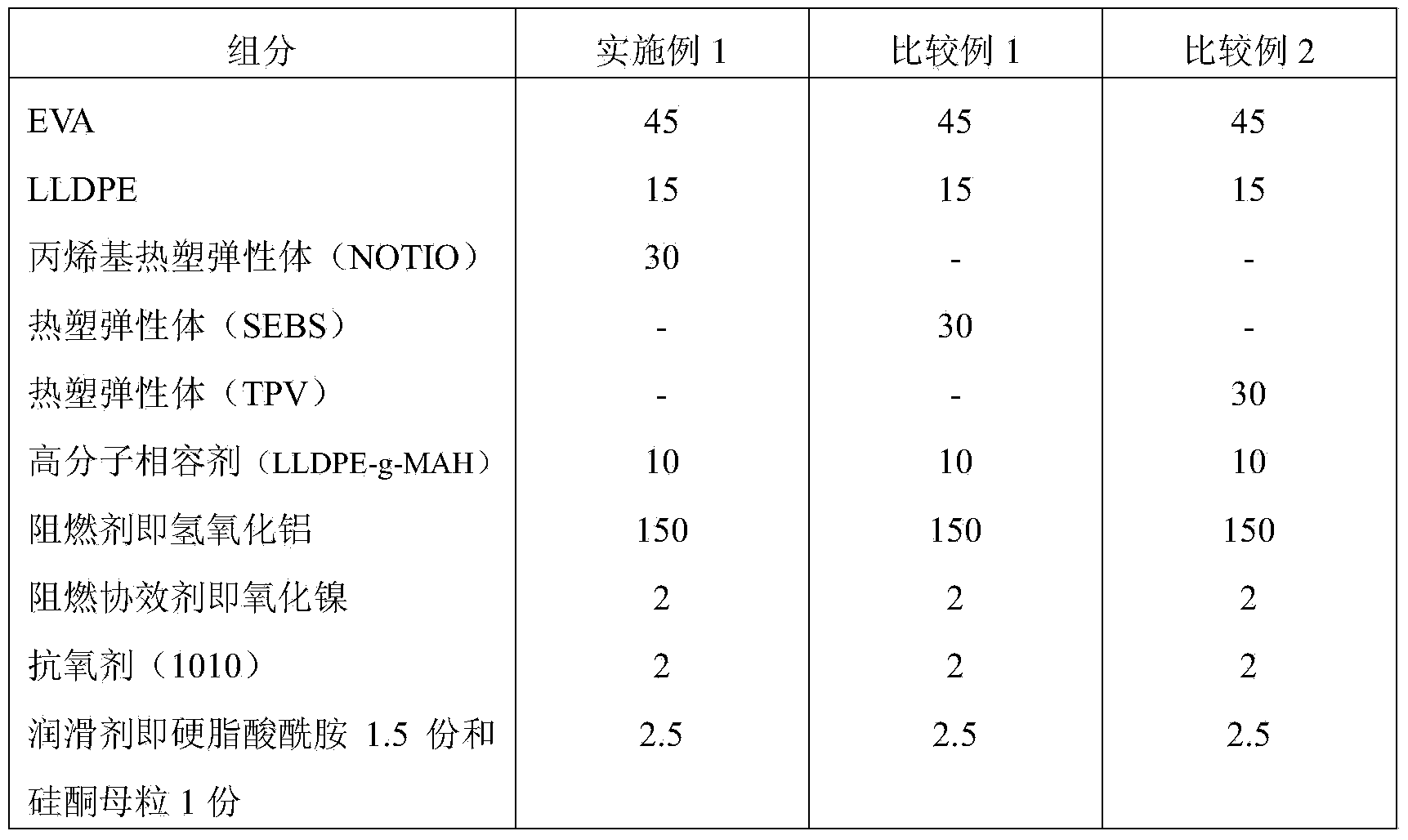

[0027] The example that present embodiment 1 compares with comparative example 1 and comparative example 2 is shown in table 1:

Embodiment 2

[0038]Embodiment 2,3,4 are shown in Table 3:

[0039] table 3

[0040]

[0041]

[0042] The EVA described in embodiment 2 in above-mentioned table 3 is ethylene vinyl acetate copolymer (EVA) that the mass percent composition of vinyl acetate is 16% for VA; 20 parts of linear low density polyethylene (LLDPE) grafted with acid anhydride and 5 parts of ethylene vinyl acetate copolymer grafted with maleic anhydride; the flame retardant is aluminum hydroxide; the flame retardant synergist is molybdenum oxide; antioxidant It is a combination of 10760.6 parts of antioxidant and 0.6 part of antioxidant DLTP; the lubricant is a combination of 1 part of polyethylene wax and 1 part of silicone masterbatch.

[0043] The EVA described in embodiment 3 in above-mentioned table 3 is ethylene vinyl acetate copolymer (EVA) that the mass percentage composition of vinyl acetate is 40% for VA; Anhydride-grafted linear low-density polyethylene; the flame retardant is a combination of 100 p...

Embodiment 5

[0049] Only change the ethylene-vinyl acetate copolymer to VA, that is, the mass percentage of vinyl acetate is 25% ethylene-vinyl acetate copolymer and change the parts by weight to 35 parts; The parts by weight are changed to 18 parts; the parts by weight of the propylene-based elastomer is catalyzed by a metallocene catalyst and the crystalline and non-crystalline structures are nanoscale propylene-based thermoplastic elastomers (NOTTO) are changed to 40 parts by weight; the polymer The compatibilizer is changed to polyolefin elastomer and the parts by weight are changed to 20 parts; the flame retardant is changed to 130 parts of magnesium-aluminum composite flame retardant, and the magnesium-aluminum composite flame retardant is magnesium hydroxide and aluminum hydroxide according to A mixture mixed in any proportion; change the flame retardant synergist to 1 part of zinc phosphate, 1 part of zinc borate, and 0.5 part of boron phosphate; change the antioxidant to 10760.3 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com