A kind of polycarbonate base composite material and its preparation method and application

A polycarbonate and composite material technology, applied in the field of material modification, can solve the problems of decreased toughness, poor light-yellowing resistance of plastic parts, and poor thermal deformation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

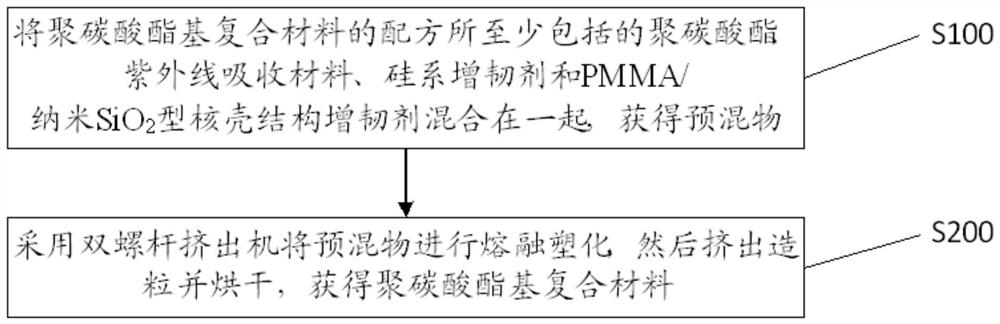

[0050] Such as figure 1 As shown, the embodiment of the present invention also provides a preparation method of a polycarbonate-based composite material, the preparation method of the polycarbonate-based composite material comprises:

[0051] The polycarbonate that the prescription of above-mentioned polycarbonate-based composite material at least includes, ultraviolet absorbing material, silicon series toughening agent and PMMA / nanometer SiO 2 The core-shell structure toughening agent is melted and plasticized to obtain polycarbonate-based composite materials.

[0052] Compared with the prior art, the beneficial effect of the preparation method of the polycarbonate-based composite material provided by the embodiment of the present invention is the same as that of the polycarbonate-based composite material provided by the above-mentioned embodiment, and will not be repeated here.

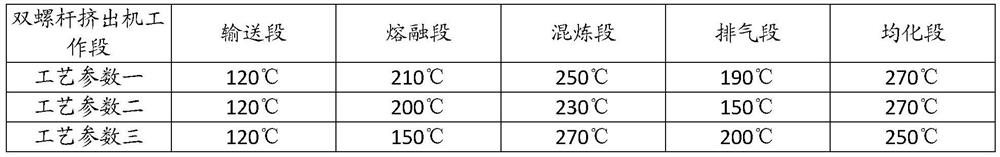

[0053] Specifically, such as figure 1 As shown, the formula of the polycarbonate-based composi...

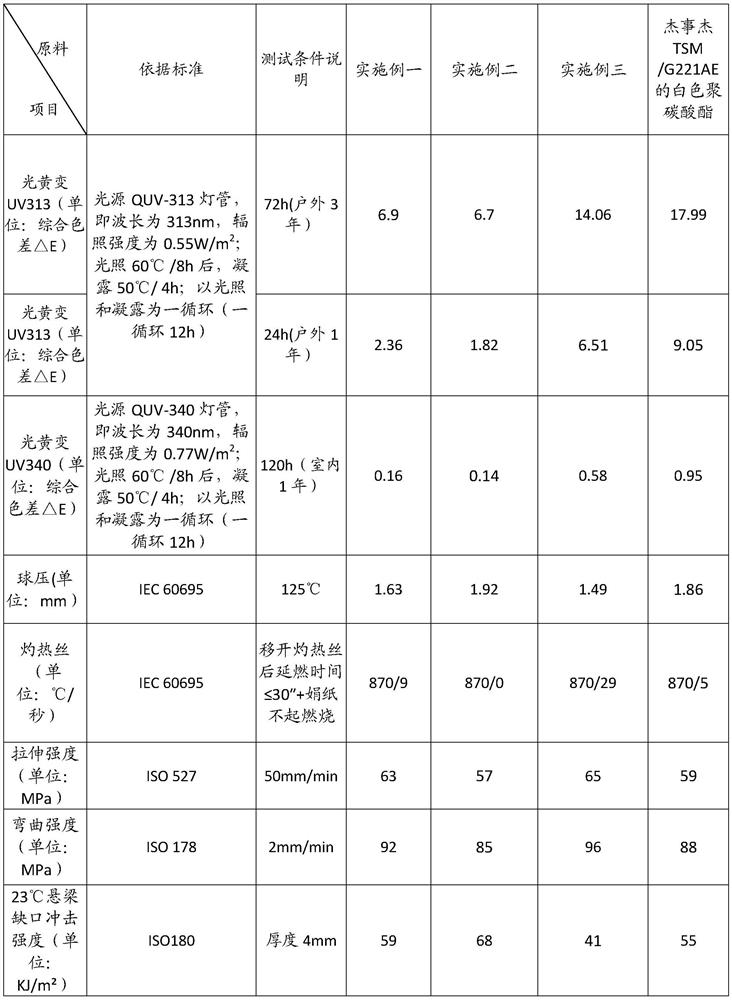

Embodiment 1

[0071] The formula used in the polycarbonate-based composite material provided in this embodiment includes polycarbonate (Covestro PC2800), silicon-propylene rubber toughening agent, PMMA / nanometer SiO 2 Type core-shell structure toughening agent, UV absorber TINUVIN 360, light stabilizer Uvinul 4050H, UV absorber TINUVIN 1600, FR-Si9805 organic silsesquioxane flame retardant, antioxidant 1010, antioxidant IRGANOX PS 802 The mass ratio of FD, titanium dioxide, EBS micronized wax lubricant P-400 and toner is 89.6:2:1.5:1:1.2:0.5:0.2:0.3:0.3:2:0.4:1. The PMMA / nano-SiO 2 The type core-shell structure toughening agent is obtained in the following way: 100g of alkylated nano-silica is added to 3000mL of 95% ethanol aqueous solution, and then 45g of polyvinylpyrrolidone is added thereto, and dispersed uniformly by ultrasonic, Get the premix. Put the premix into a sealed reaction kettle, and feed nitrogen into the reaction kettle. The reactor was heated with an oil bath and the pr...

Embodiment 2

[0074] The formula used in the polycarbonate-based composite material provided in this embodiment includes polycarbonate (Covestro PC2800), silicon-propylene rubber toughening agent, PMMA / nanometer SiO 2 Type core-shell structure toughening agent, UV absorber TINUVIN 360, light stabilizer Uvinul 4050H, UV absorber TINUVIN 1600, FR-Si9805 organic silsesquioxane flame retardant, antioxidant 1010, antioxidant IRGANOX PS 802 The mass ratio of FD, titanium dioxide, EBS micronized wax lubricant P-400 and toner is 80.5:4:2.5:2:2:1:2:0.8:0.8:2:0.4:1. The PMMA / nano-SiO 2 The type core-shell structure toughening agent is obtained in the following way: 100g of alkylated nano-silica is added to 3000mL of 95% ethanol aqueous solution, and then 45g of polyvinylpyrrolidone is added thereto, and dispersed uniformly by ultrasonic, Get the premix. Put the premix into a sealed reaction kettle, and feed nitrogen into the reaction kettle. The reactor was heated with an oil bath and the premix w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com