Low-smoke density additive-type flame retardant resin and application thereof

A flame retardant resin, smoke density technology, applied in the field of flame retardant resin, can solve the problems of limitation and high resin viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

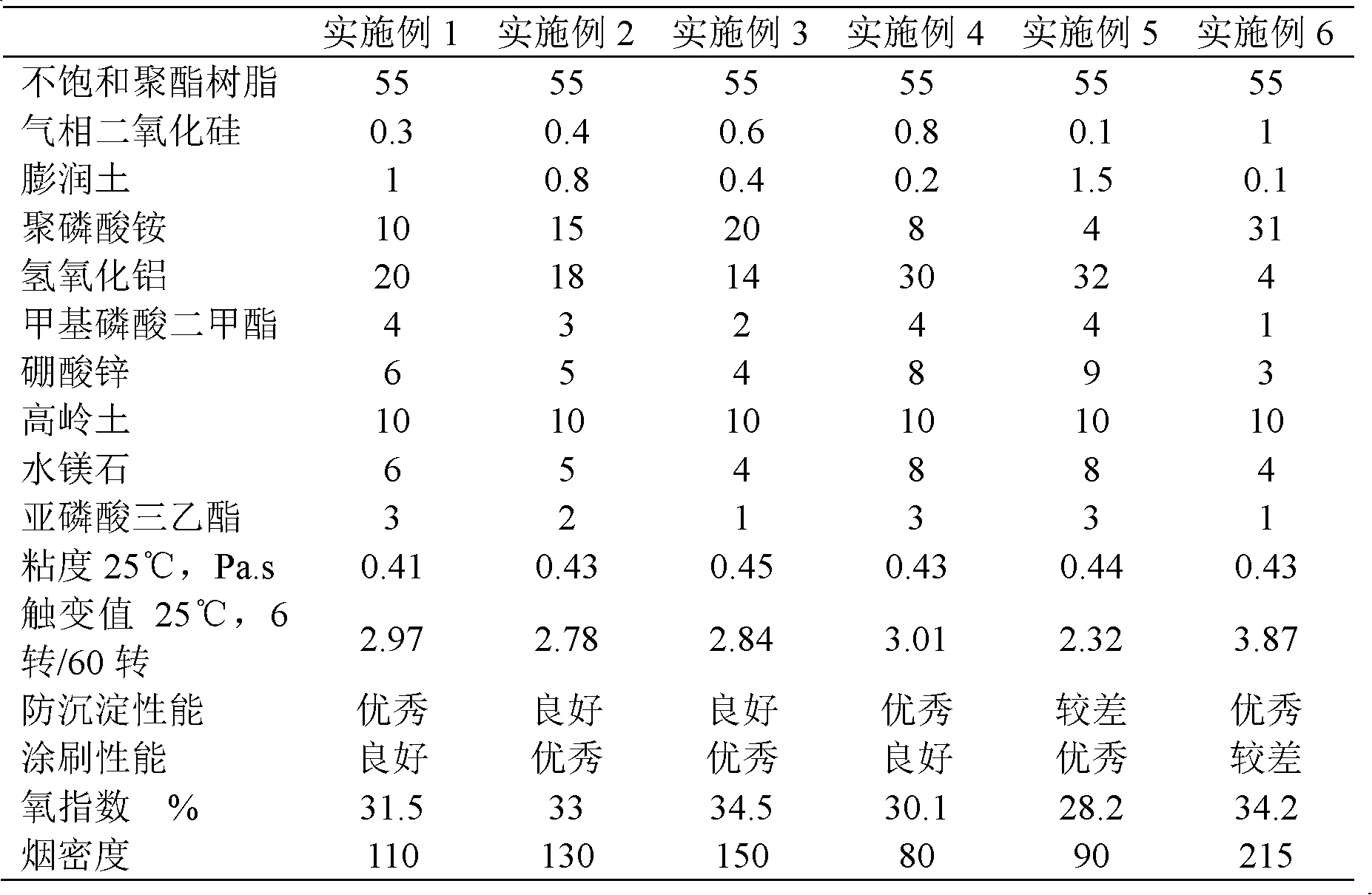

Embodiment 1

[0050] A low-smoke density additive flame-retardant resin in this embodiment includes 55 parts of unsaturated polyester resin, 0.3 parts of fumed silica, 1 part of bentonite, 10 parts of ammonium polyphosphate, 20 parts of aluminum hydroxide, methylphosphoric acid 4 parts of dimethyl ester, 6 parts of zinc borate, 10 parts of kaolin, 6 parts of brucite and 3 parts of triethyl phosphite.

[0051] The production method is as follows:

[0052] (1) First add 55 parts of unsaturated polyester resin into a container with a cooling water jacket, add a mixture of 0.3 parts of fumed silica and 1 part of bentonite again, start the high-speed disperser to stir, and at the same time add The container is covered with cooling water, and the stirring speed is increased to 3000r / min within 2 minutes, and the high-speed dispersion is 8-10 minutes;

[0053] (2) Add 10 parts of ammonium polyphosphate, 20 parts of aluminum hydroxide, 4 parts of dimethyl phosphate, 6 parts of zinc borate, 10 part...

Embodiment 2

[0056] A low-smoke density additive flame-retardant resin in this embodiment includes 55 parts of unsaturated polyester resin, 0.4 parts of fumed silica, 0.8 parts of bentonite, 15 parts of ammonium polyphosphate, 18 parts of aluminum hydroxide, methylphosphoric acid 3 parts of dimethyl ester, 5 parts of zinc borate, 10 parts of kaolin, 5 parts of brucite and 2 parts of triethyl phosphite.

[0057] The preparation method is the same as in Example 1.

Embodiment 3

[0059] A low-smoke density additive flame-retardant resin in this embodiment includes 55 parts of unsaturated polyester resin, 0.6 parts of fumed silica, 0.4 parts of bentonite, 20 parts of ammonium polyphosphate, 14 parts of aluminum hydroxide, methylphosphoric acid 2 parts of dimethyl ester, 4 parts of zinc borate, 10 parts of kaolin, 4 parts of brucite and 1 part of triethyl phosphite.

[0060] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com