Microwave induced intumescent flame-retardant silane crosslinked polyolefin sheath material for cables and preparation method thereof

A polyolefin sheathed, intumescent flame retardant technology, applied to insulated cables, cables, conductors, etc., can solve the problems of poor flame retardant effect, long boiling time, poor product stability, etc., to improve water resistance and easy operation. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

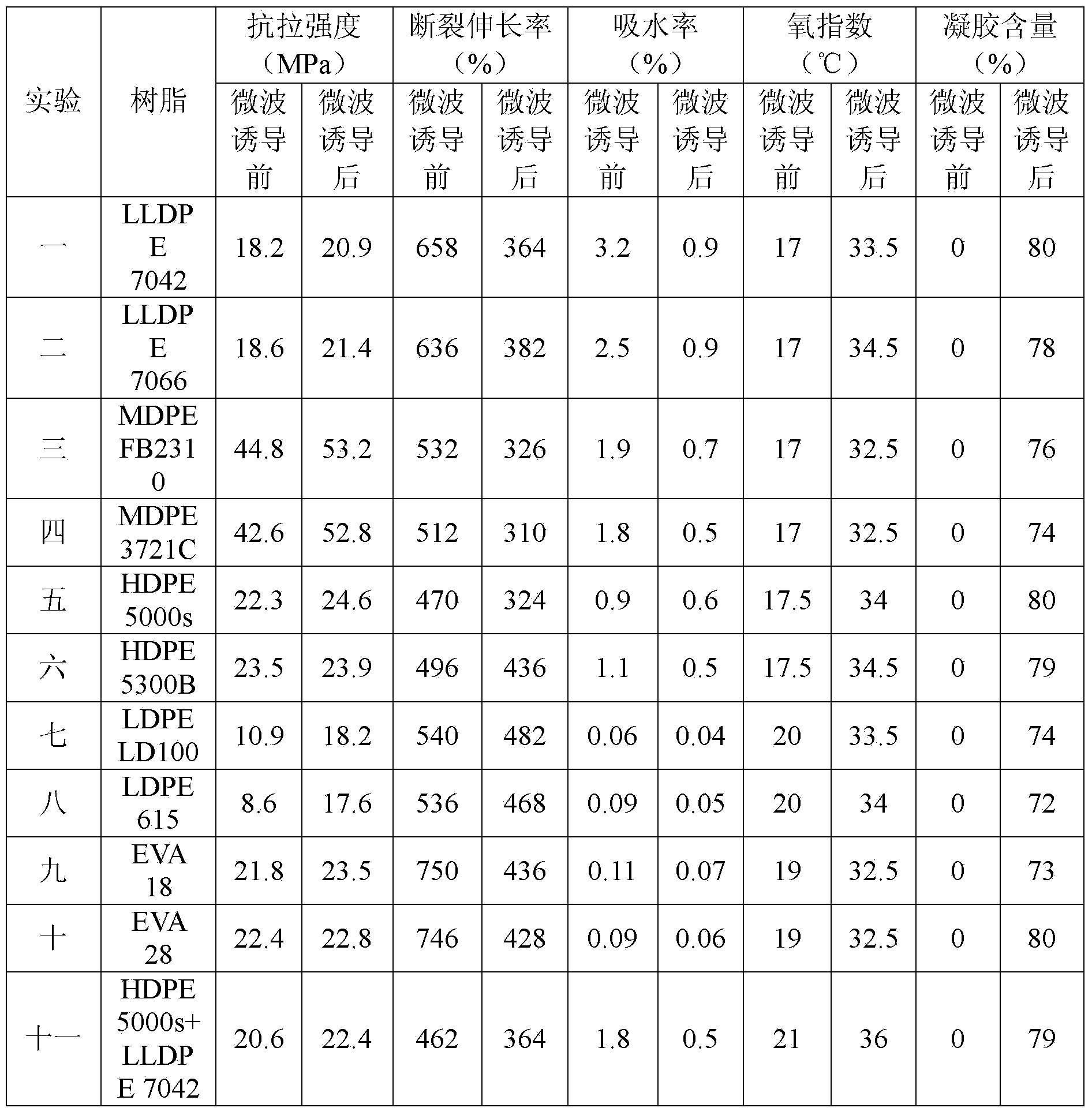

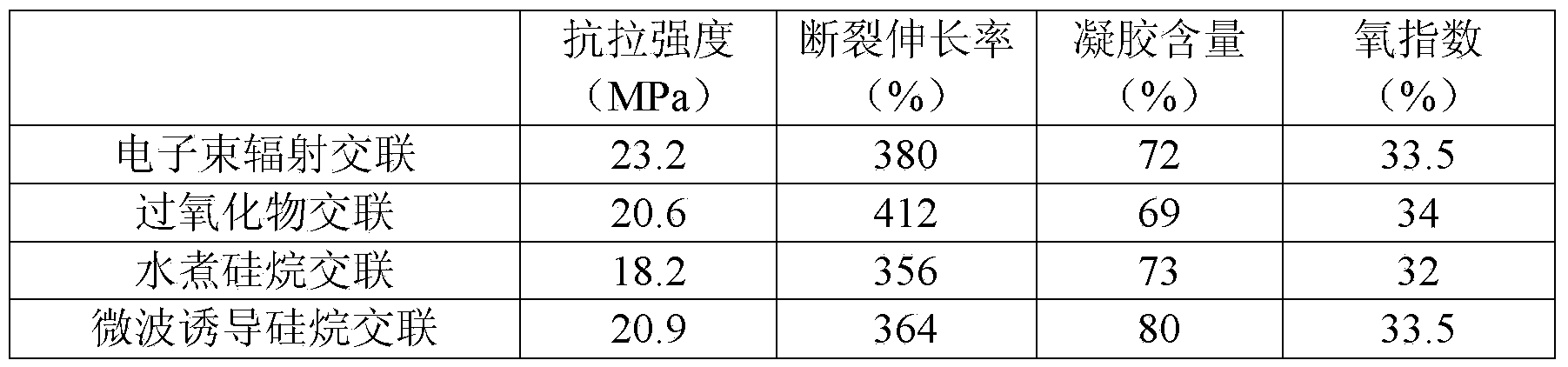

[0028] Specific embodiment 1: The microwave-induced expansion flame-retardant polyolefin sheath material for silane cross-linked cable of this embodiment consists of 100 parts by weight of dried polyolefin resin, 25-80 parts of intumescent flame retardant, and 0.1-4 parts by weight It is made of silane coupling agent, 0.2-3 parts microwave absorbent, 0.1-4 parts water producing agent, 0.3-5 parts multifunctional cross-linking agent, 0.01-5 parts cross-linking accelerator and 0.07-0.5 parts antioxidant.

specific Embodiment approach 2

[0029] Specific embodiment two: this embodiment is different from specific embodiment one in that the polyolefin resin is high-density polyethylene, medium-density polyethylene, low-density polyethylene, low-density linear polyethylene, ethylene-vinyl acetate copolymer, and One or a combination of several polyolefin elastomers. Others are the same as the first embodiment.

[0030] When the polyolefin resin described in the present embodiment is a composition, there is an arbitrary ratio among the components.

specific Embodiment approach 3

[0031] Specific embodiment three: This embodiment is different from one of specific embodiments one or two in that the intumescent flame retardant is intumescent flame retardant IFR-P500, intumescent flame retardant IFR-P601, intumescent flame retardant One or a combination of combustible agent IFR-P602, intumescent flame retardant IFR-P603, intumescent flame retardant IFR-T800 and intumescent flame retardant IFR-MT800. Others are different from the first or second embodiment.

[0032] When the intumescent flame retardant described in this embodiment is a composition, there is an arbitrary ratio among the components.

[0033] The intumescent flame retardant IFR-P500, the intumescent flame retardant IFR-P601, the intumescent flame retardant IFR-P602, the intumescent flame retardant IFR-P603, the intumescent flame retardant IFR- T800 and intumescent flame retardant IFR-MT800 are manufactured by Heilongjiang Runte Technology Co., Ltd.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com