Crosslinked halogen-free flame-retardant cable material

A technology of flame retardant cable material and inorganic flame retardant, used in plastic/resin/wax insulators, organic insulators, etc. Properties and flame retardant properties, improved dispersibility, high oxygen index effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

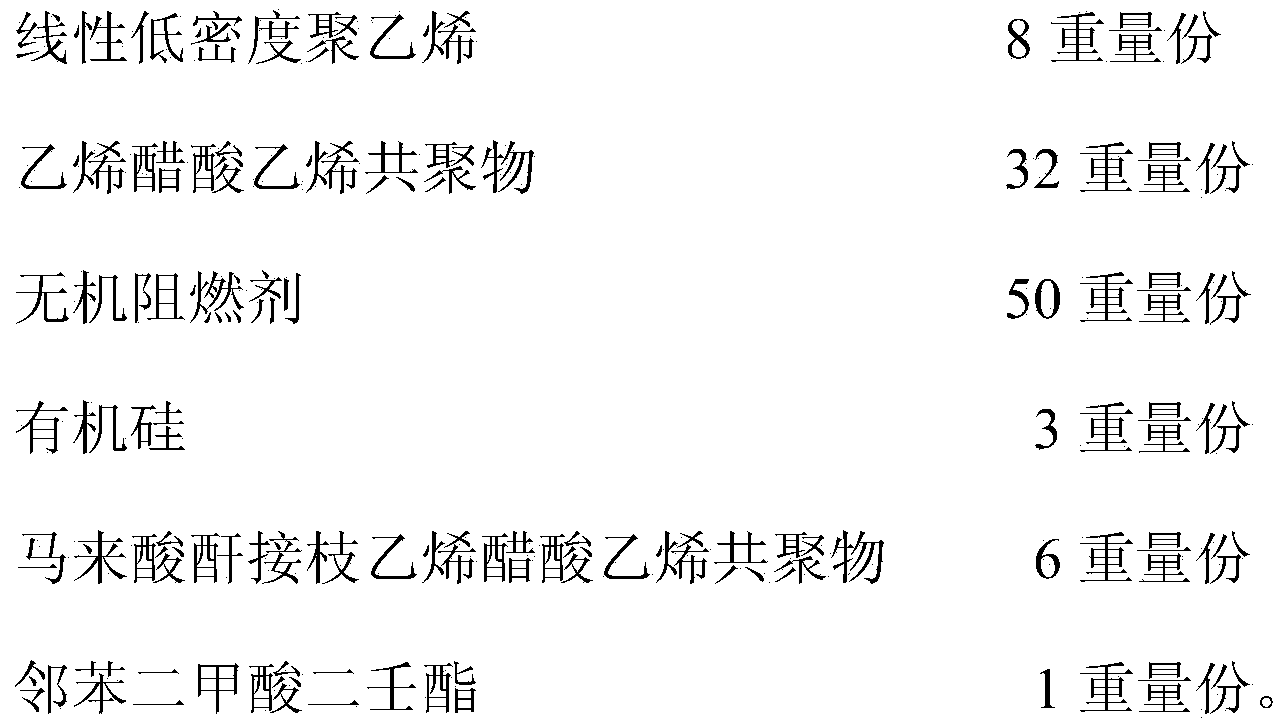

[0024] All ingredients were melt blended according to the following recipe:

[0025]

[0026] Specifically, the matrix resin, inorganic flame retardant, flame retardant synergist, compatibilizer and crosslinking agent are weighed in proportion, after mixing, they are added to a two-roll mill for melting and mixing, and the mixing temperature is controlled at Below 125°C, the mixing time is 5 minutes, and the tablets are ready for use.

[0027] The above-mentioned blend was molded into a tablet and vulcanized at 180°C for 15 minutes to prepare a sample; finally, the mechanical properties and oxygen index of the finished product were tested according to the national standard, and the results are shown in Table 1:

[0028] The performance data of the cable material made by table 1, embodiment 1

[0029] performance

Embodiment 2

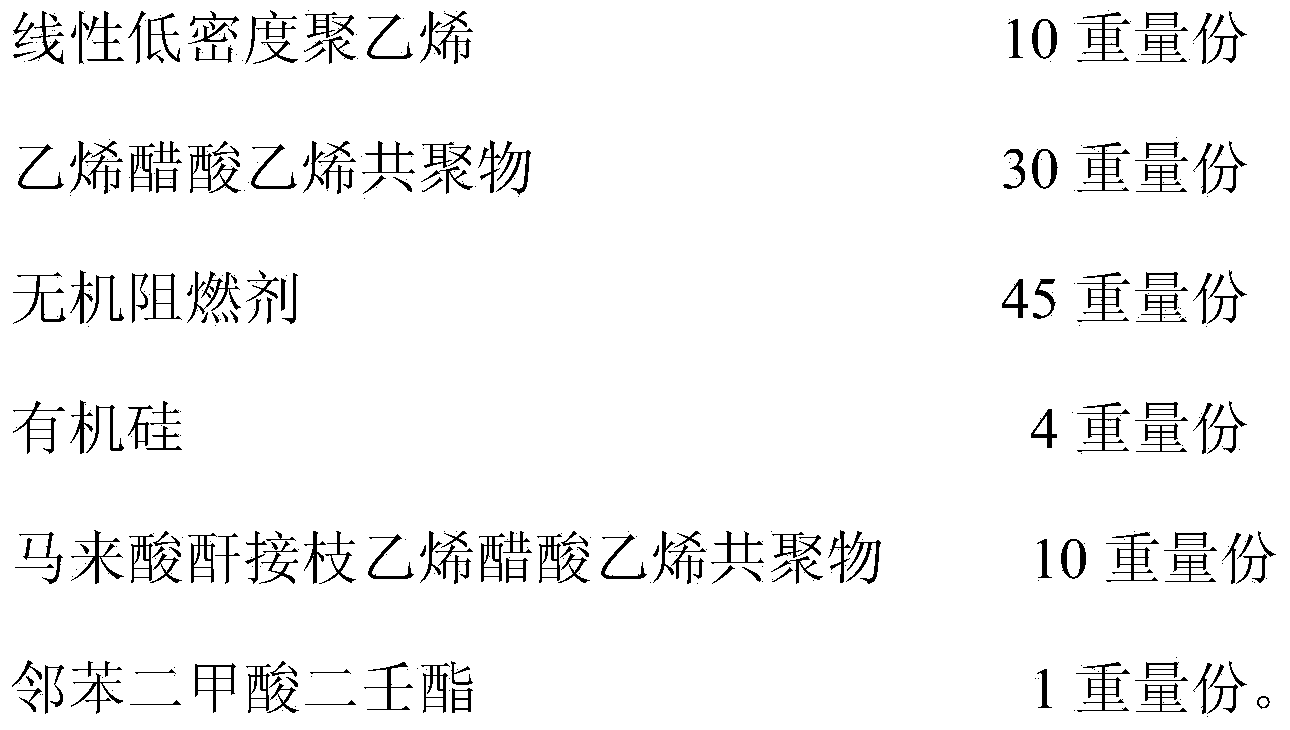

[0031] All ingredients were melt blended according to the following recipe:

[0032]

[0033] Specifically, the matrix resin, inorganic flame retardant, flame retardant synergist, compatibilizer and crosslinking agent are weighed in proportion, after mixing, they are added to a two-roll mill for melting and mixing, and the mixing temperature is controlled at Below 125°C, the mixing time is 5 minutes, and the tablets are ready for use.

[0034] Take the above-mentioned blend and mold it into a tablet and vulcanize it at 180°C for 15 minutes to prepare a sample; finally, test the mechanical properties and oxygen index of the finished product according to the national standard, and the results are shown in Table 2:

[0035] The performance data of the cable material made by table 2, embodiment 2

[0036] performance

Embodiment 3

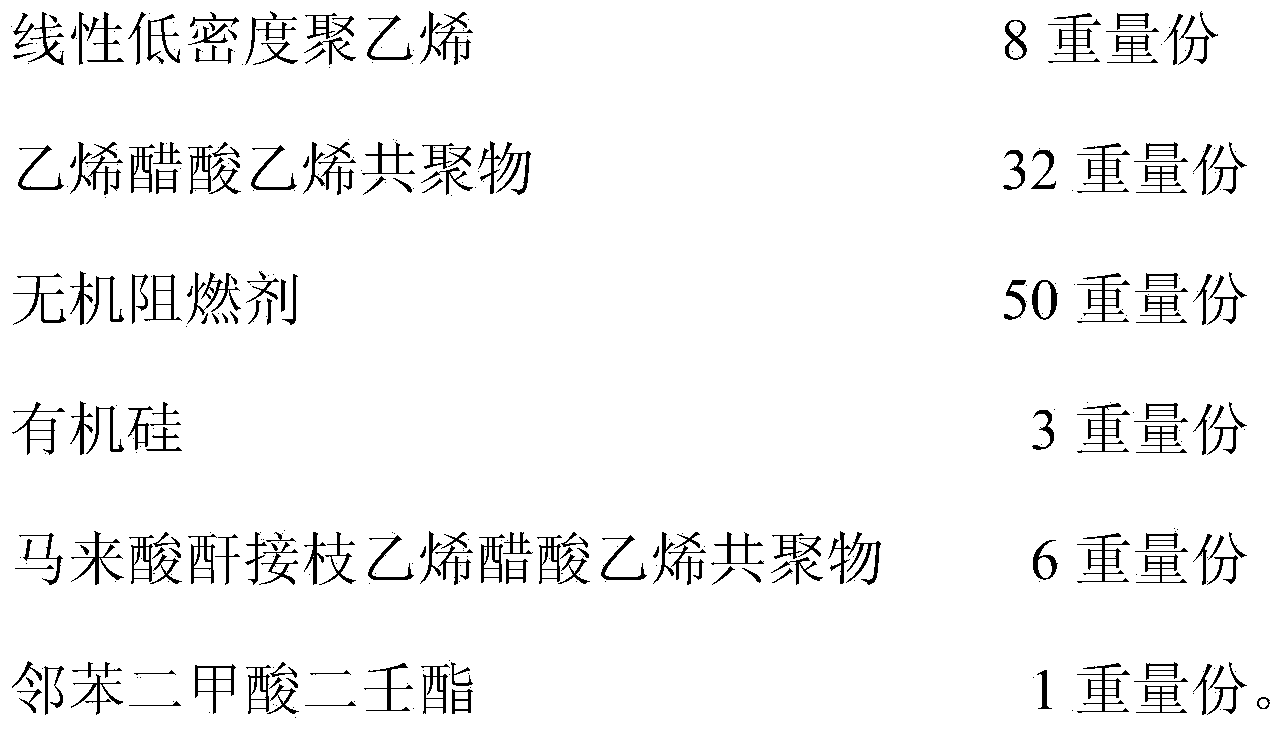

[0038] All ingredients were melt blended according to the following recipe:

[0039]

[0040]

[0041] Specifically, the matrix resin, inorganic flame retardant, flame retardant synergist, compatibilizer and crosslinking agent are weighed in proportion, after mixing, they are added to a two-roll mill for melting and mixing, and the mixing temperature is controlled at Below 125°C, the mixing time is 5 minutes, and the tablets are ready for use.

[0042] The above-mentioned blend was molded into a tablet and vulcanized at 180°C for 15 minutes to prepare a sample; finally, the mechanical properties and oxygen index of the finished product were tested according to the national standard, and the results are shown in Table 3:

[0043] The performance data of the cable material made by table 3, embodiment 3

[0044] performance

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com