Silsesquioxane cross-linked silicon nitrogen phosphor synergic anti-flaming water-borne epoxy resin and preparation method thereof

A technology of siloxane epoxy resin and water-based epoxy resin, which is applied in the direction of epoxy resin coating, coating, anti-corrosion coating, etc., can solve the problems of high flame retardancy, thick coating thickness of heat insulation function, etc., and achieve improved resistance Combustibility, low cost, high binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

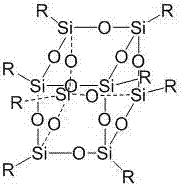

[0051] Embodiment 1: Preparation of cage silsesquioxane

[0052] In a three-neck flask equipped with stirring, dropping funnel and thermometer, add 200ml of isopropanol (IPA) and 15.6g of 5% tetramethylammonium hydroxide (TMAH) aqueous solution, and add 30ml of isopropanol and 60.38g of 3-glycidyl etheroxypropyltrimethoxysilane, and then drop the mixed solution in the dropping funnel into the reaction vessel under stirring, and complete the dropwise addition within 60min. After the dropwise addition, continue to stir at room temperature for 6 hours, then distill off isopropanol under reduced pressure, then add 200ml of toluene to dissolve, reflux at about 80°C for 4-8 hours, adjust the pH of the solution to neutral, and distill under reduced pressure Remove the toluene, and vacuum-dry at a temperature of 60° C. to obtain a colorless and transparent viscous liquid, which is a cage silsesquioxane whose active group R is glycidyl etheroxypropyl.

Embodiment 2

[0053] Embodiment 2: Preparation of cage silsesquioxane

[0054] In a three-neck flask equipped with stirring, dropping funnel and thermometer, add 100 parts of isopropanol (IPA) and 9 parts of 5% tetramethylammonium hydroxide (TMAH) aqueous solution, and add 15 parts of isopropyl alcohol (IPA) into the dropping funnel. propanol and 28 parts of 3-(2,3-glycidoxy)propyltrimethoxysilane, and then add the mixed solution in the dropping funnel dropwise to the reaction vessel under stirring, and the dropwise addition is completed within 60 minutes. After the dropwise addition, continue to stir at room temperature for 6 hours, then distill off isopropanol under reduced pressure, add 100 parts of chloroform to dissolve, reflux at about 80°C for 4-8 hours, distill out chloroform under reduced pressure, After drying under vacuum, a colorless and transparent viscous liquid is obtained, which is a cage silsesquioxane whose active group R is 3-(2,3-glycidoxy)propyl.

Embodiment 3

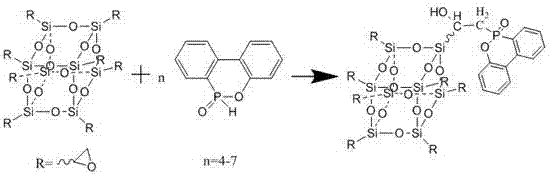

[0055] Embodiment 3: the preparation of the silsesquioxane epoxy resin curing agent containing silicon nitrogen phosphorus

[0056] Dissolve 5 parts of the cage silsesquioxane prepared in Example 1 in 100 parts of chloroform, and after refluxing for half an hour, add 5 parts of DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene- 10-oxide) and a corresponding amount of catalyst triphenylphosphine, continue to reflux reaction for 3-5h, siloxane and DOPO are connected by ether bond, and generate hydroxyl group; then add 5 parts of diethylenetriamine and the remaining 3-glycidol Propoxy reaction, reflux reaction for about 1h, the product is washed with water and then the solvent is removed in a rotary evaporator, the product is dried for 1-3h, and ground to 100-200 mesh to obtain a silsesquioxane epoxy containing silicon, nitrogen and phosphorus Resin curing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com