Phosphorus-containing macromolecule intumescent flame retardant char forming agent as well as preparation method thereof and intumescent flame retardant formed by char forming agent

An intumescent flame retardant and intumescent flame retardant technology, applied in the field of intumescent flame retardants, can solve the problems of insufficient char-forming ability of macromolecular intumescent flame retardant charring agents, reduce moisture absorption and improve flame retardant efficiency , the effect of improving the ability to form carbon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

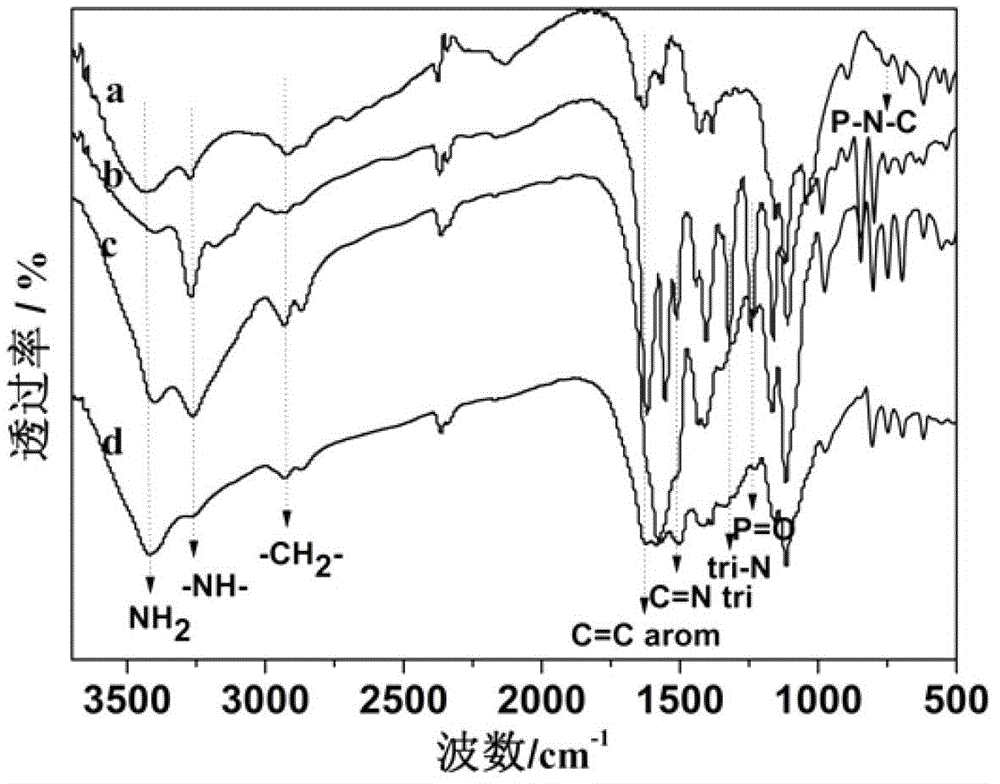

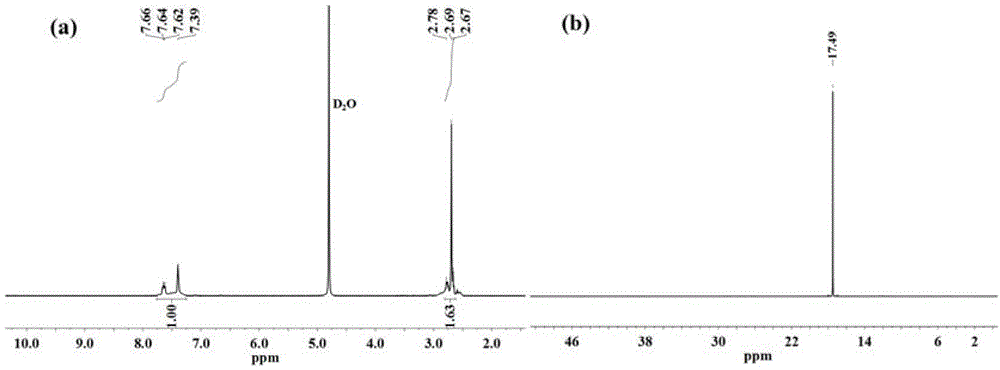

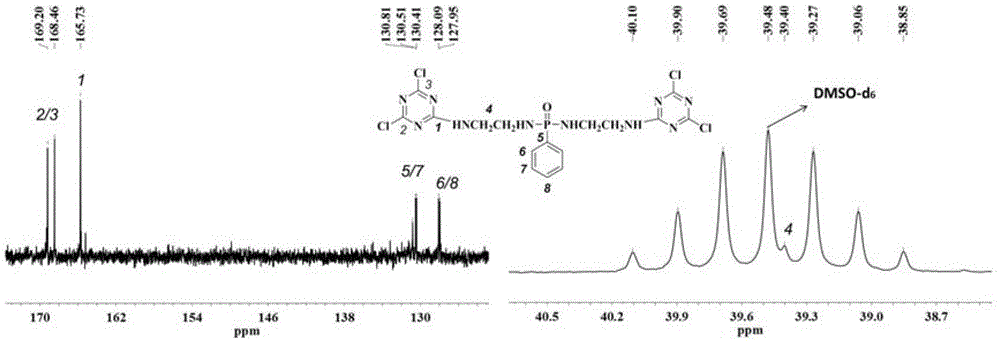

[0043] Dissolve 4 mol of ethylenediamine in 500 mL of chloroform, then add dropwise 1.0 mol of phenylphosphonic dichloride dissolved in 100 mL of chloroform while stirring, and control the temperature of the solution between 0-5°C; After finishing the phenylphosphonic dichloride solution, react for 6 hours, then raise the temperature to 40° C. and react for 1 hour, and filter to remove by-product ethylenediamine hydrochloride to obtain a chloroform solution of phosphorus-containing diamine monomer.

[0044] Disperse 1.0 mol of cyanuric chloride evenly in 500 mL of chloroform, then keep the temperature at 0-5°C, add dropwise 0.5 mol of phosphorus-containing diamine monomer in chloroform and dissolve in 100 mL of deionized water while stirring 0.5 mol of potassium carbonate, the two should be added dropwise at the same time, and the pH value of the reaction system is kept at 5~7 by controlling the drop rate of the potassium carbonate solution during the dropping process. 3 hours...

Embodiment 2

[0049] First dissolve 4 mol of diethylenetriamine in 500 mL of chloroform, then add dropwise 1.0 mol of phenylphosphonic dichloride dissolved in 100 mL of chloroform while stirring, and control the solution temperature between 0-5°C; After adding the phenylphosphonic acid dichloride solution, react for 6 hours, then raise the temperature to 40° C. and react for 1 hour, filter to remove by-product diethylenetriamine hydrochloride, and obtain a chloroform solution of phosphorus-containing diamine monomer.

[0050] Disperse 1.0 mol of cyanuric chloride evenly in 500 mL of chloroform, then keep the temperature at 0-5°C, add dropwise 0.6 mol of phosphorus-containing diamine monomer in chloroform and dissolve in 100 mL of deionized water while stirring 1.0 mol of sodium hydroxide, the two should be added dropwise at the same time, and the pH value of the reaction system should be kept at 5~7 by controlling the drop rate of the sodium hydroxide solution during the dropwise addition pr...

Embodiment 3

[0052] Firstly dissolve 4 mol of butanediamine in 500 mL of toluene, then add dropwise 1.0 mol of phenyl dichlorophosphate dissolved in 100 mL of toluene while stirring, and control the temperature of the solution between 0-5°C; The phenyl dichlorophosphate solution was reacted for 6 hours, then heated to 40°C for 1 hour, and the by-product butanediamine hydrochloride was removed by filtration to obtain a toluene solution of phosphorus-containing diamine monomer.

[0053] Disperse 1.0 mol cyanuric chloride evenly in 500 mL toluene, then keep the temperature at 0-5°C, add dropwise 0.7 mol phosphorus-containing diamine monomer toluene solution and dissolve in 100 mL deionized water while stirring 1.0 mol of potassium hydroxide, the two should be added dropwise at the same time, and the pH value of the reaction system should be kept at 5~7 by controlling the drop rate of the potassium hydroxide solution during the dropwise addition process. After the dropwise addition, keep the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com