Flame retardant polypropylene resin blend and preparation method thereof

A technology for flame retardant polypropylene and polypropylene resin, applied in the field of flame retardant polypropylene resin blend and its preparation, can solve the problems of high specific gravity, easy migration of flame retardants, low thermal oxygen resistance and light aging resistance, etc. Achieve the effect of realizing large-scale industrial production, excellent light aging resistance, and reducing the migration of flame retardants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

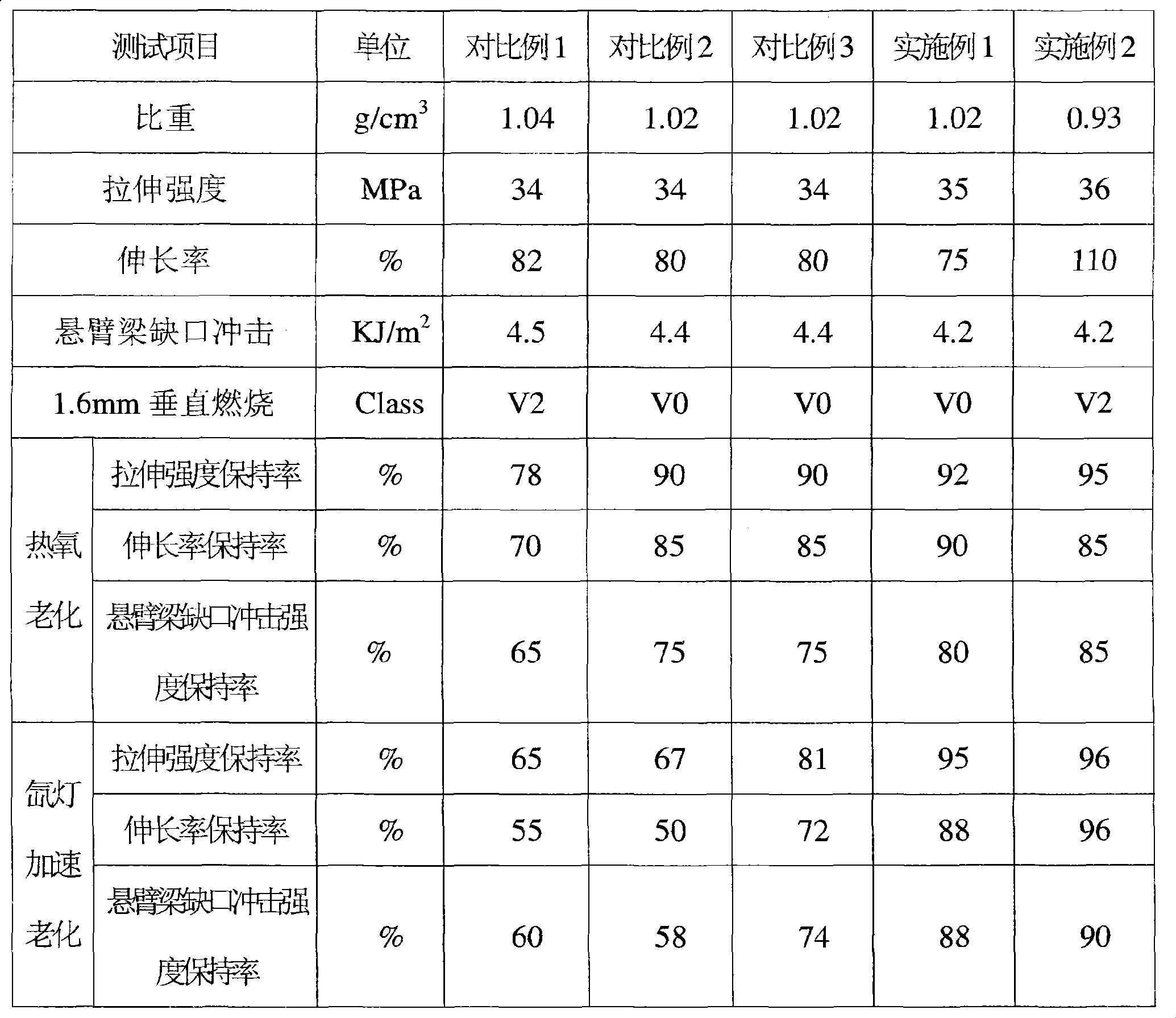

[0024] According to the flame-retardant polypropylene resin blend prepared in Table 1, various items are tested, and the test items and test results thereof are shown in Table 2: Embodiment 1 is to further optimize the long-term aging resistance of the material. After introducing tetrabromobisphenol After grafting polypropylene with epoxy oligomer and maleic anhydride, it can further improve the resistance to heat, oxygen and light aging of the system.

Embodiment 2

[0026] All materials are prepared according to the flame retardant polypropylene resin blend in Example 2 in Table 1, and its density is only 0.93g / cm 3 , according to UL test its flame retardant grade is V2. After thermal oxygen aging test and xenon arc accelerated aging test, its performance retention rate is very high, and it also slows down the rate of precipitation and migration of flame retardants.

Embodiment 3

[0028] According to the flame retardant polypropylene resin blend prepared in Example 3 in Table 1, its flame retardant performance is only V2, and it has excellent thermal oxygen resistance and light aging resistance. At the same time, it can pass the glow wire temperature test and needle flame test at 850°C according to IEC60695.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com