Full-water-based low-density soft polyurethane spraying composite polyether and preparation method thereof

A technology of soft polyurethane and combined polyether, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of low bonding strength between foam and wall, affecting the quality of engineering construction, and poor foam resilience, etc., to achieve The preparation method is simple and easy to operate, the effect of avoiding mold production and low foam density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

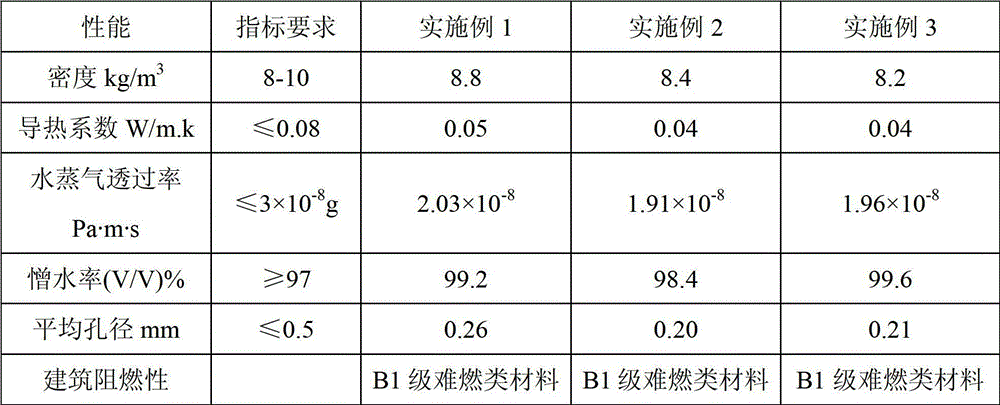

Examples

Embodiment 1

[0040] (1) First put 60 parts of EP-330N, 10 parts of NT-403A and 30 parts of CF-6255 into the reactor;

[0041] (2) Add other raw materials of component A, physically mix and stir at room temperature for 1.5 hours, then fill in barrels, and complete the production of component A;

[0042] (3) According to the mass ratio of component A: polymethyl polyphenyl polyisocyanate or diphenylmethane diisocyanate (component B) of 100:100, add polymethyl polyphenyl polyisocyanate and pass through a high-pressure spraying machine Mix evenly, atomize and foam through a high-pressure foaming machine, and foam-form and mature for 24 hours to obtain the product.

[0043] Wherein: A component is the raw material of following mass ratio:

[0044] EP-330N: 60

[0045] NT-403A: 10

[0046] CF-6255: 30

[0047] EG: 3

[0048] B8870: 0.8

[0049] LK221: 1.2

[0050] Deionized water: 25

[0051] Catalyst A1:2

[0052] PT303: 1.7

[0053] PT304: 0.5

[0054] TCPP: 10

[0055] TEP: 10

...

Embodiment 2

[0060] (1) Put 40 parts of EP-330N, 20 parts of NT-403A and 30 parts of CF-6255 into the reaction kettle and stir;

[0061] (2) Add other raw materials of component A, physically mix and stir at room temperature for 1.5 hours, then fill in barrels, and complete the production of component A;

[0062](3) According to the mass ratio of component A: polymethyl polyphenyl polyisocyanate or diphenylmethane diisocyanate (component B) of 100:105, add polymethyl polyphenyl polyisocyanate and pass through a high-pressure spraying machine Mix evenly, spray and foam through a high-pressure foaming machine, foam molding and aging for 23 hours to obtain the product.

[0063] Wherein: A component is the raw material of following mass ratio:

[0064] EP-330N: 50

[0065] NT-403A: 20

[0066] CF-6255: 30

[0067] EG: 6

[0068] B8870: 1.0

[0069] LK221: 0.5

[0070] Deionized water: 22

[0071] Catalyst A1: 3.5

[0072] PT303: 2.5

[0073] PT306: 4.0

[0074] TCPP: 3.5

[0075] T...

Embodiment 3

[0078] (1) Put 50 parts of EP-330N, 20 parts of NT-403A and 5 parts of CF-6255 into the reaction kettle and stir;

[0079] (2) Add the other raw materials of component A, physically mix and stir at room temperature for 1.2 hours, fill in barrels, and complete the production of component A;

[0080] (3) According to the mass ratio of component A: polymethyl polyphenyl polyisocyanate or diphenylmethane diisocyanate (component B) of 100:102, add diphenylmethane diisocyanate and mix evenly through a high-pressure sprayer , after atomization and foaming by high-pressure foaming machine, foam molding and aging for 24 hours, the product is obtained.

[0081] Wherein: A component is the raw material of following mass ratio:

[0082] EP-330N: 60

[0083] NT-403A: 20

[0084] CF-6255: 20

[0085] DEG: 9

[0086] B8870: 0.1

[0087] LK221: 0.1

[0088] Deionized water: 10

[0089] Catalyst A1:5

[0090] PT303: 5.5

[0091] PT304: 5.5

[0092] TCPP: 25

[0093] TEP: 25

[009...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com