Modified magnesium hydroxide fire retardant and high impact polystyrene composite inflaming-retarding material formed by modified magnesium hydroxide fire retardant and manufacturing method

A technology of magnesium hydroxide and polystyrene, applied in the treatment of dyed polymer organic compounds, fibrous fillers, etc., can solve the problems of sacrificing polymer materials, affecting the cost of HIPS/MH composite materials, and the difficulty of evenly dispersing MH

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

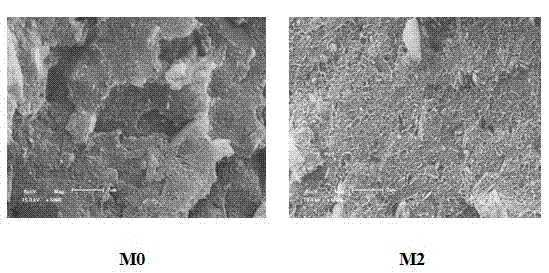

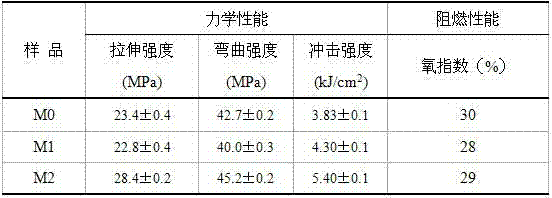

[0026] Soak 100 grams of HIPS (Nanjing Sinopec Yangzi Petrochemical Co., Ltd., average particle size: 4 mesh) in 100 ml of 98% (mass percent concentration, the same below) concentrated sulfuric acid for 10 minutes at room temperature, drain and wash To neutral, the sulfonated high-impact polystyrene with a sulfonation degree of 24.1% is obtained. MH powder (average particle size: 2.21 μm, BET specific surface 6.79 m 2 / g, Yixing Venture Company) and sulfonated high-impact polystyrene were added into a high-speed mixer and stirred for 20 minutes for modification, wherein the mass of sulfonated high-impact polystyrene was 15% of MH, and the modified MH was obtained. Then HIPS (Nanjing Sinopec Yangzi Petrochemical Co., Ltd.), modified MH and additives (PPO, RDP, TPP and EBS) were mixed with a single-roll extruder for 30 minutes and pelletized, wherein: HIPS, modified MH, The mass percentages of PPO, RDP, TPP and EBS in the composite material were 50, 31, 8, 4, 6 and 1 % respecti...

Embodiment 2

[0031] Soak 100 grams of HIPS (Nanjing Sinopec Yangzi Petrochemical Co., Ltd., average particle size 1 mesh) in 100 ml of 80% concentrated sulfuric acid at room temperature for sulfonation for 15 minutes, wash until neutral, and obtain a sulfonation degree of 10%. High impact polystyrene. MH powder (average particle size: 100 μm, BET specific surface 0.52 m 2 / g, Yixing Venture Company) and sulfonated high-impact polystyrene were added into a high-speed mixer and stirred for 20 minutes for modification, wherein the mass of sulfonated high-impact polystyrene was 10% of MH to obtain modified MH. Then HIPS (Nanjing Sinopec Yangzi Petrochemical Co., Ltd.), modified MH and additives (PPO, RDP, TPP and EBS) were mixed with a single-roll extruder for 60 minutes and pelletized, wherein: HIPS, modified MH, The mass percentages of PPO, RDP, TPP and EBS in the composite material were 60, 21, 8, 4, 6 and 1%, respectively, and the composite flame retardant material was obtained. Then use...

Embodiment 3

[0033] Soak 100 grams of HIPS (Nanjing Sinopec Yangzi Petrochemical Co., Ltd., average particle size: 10 mesh) in 100 milliliters of 50% concentrated sulfuric acid at room temperature for sulfonation for 100 minutes, drain, wash until neutral, and obtain a sulfonation degree of 80% sulfonated high impact polystyrene. MH powder (average particle size: 1 μm, BET specific surface 19.8 m 2 / g, Yixing Venture Company) and sulfonated high-impact polystyrene were added to a high-speed mixer and stirred for 30 minutes for modification, wherein the mass of sulfonated high-impact polystyrene was 20% of MH to obtain modified MH. Then HIPS (Nanjing Sinopec Yangzi Petrochemical Co., Ltd.), modified MH and additives (PPO, RDP, TPP and EBS) were mixed with a single-roll extruder for 60 minutes and pelletized, wherein: HIPS, modified MH, The mass percentages of PPO, RDP, TPP and EBS in the composite material were 55, 26, 8, 4, 6 and 1%, respectively, and the composite flame retardant materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com