Phosphorus-containing polyol, preparation method thereof and flame-retardant polyurethane containing same

A polyol and diol technology, applied in the field of flame retardant polyurethane, can solve the problems of destroying the ratio of soft-hard segments and reducing the elasticity of polyurethane resin, achieving the effects of low volatility and greatly reducing mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

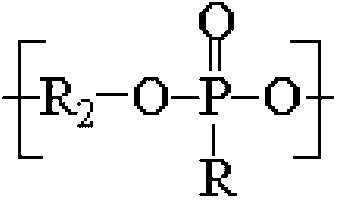

[0036]In one embodiment of the present invention, a method for preparing the above-mentioned phosphorus-containing polyol is also provided, which uses phosphonate ester and diol as raw materials, and obtains polyphosphine terminated with hydroxyl groups through transesterification condensation polymerization. esters. Among them, the raw materials for the preparation of phosphorus-containing polyols include: phosphonate esters with the structure in formula (2) and one or more diols with the structure in formula (3),

[0037]

[0038] HO-R 2 -OH (3)

[0039] In formula (2), R is methyl, ethyl, nitrile or phenyl; R 1 is methyl, ethyl or phenyl, in formula (3) R 2 is an alkyl or aryl group;

[0040] The preparation method of phosphorus-containing polyol comprises the following: S1, the phosphonate of mx mol is mixed with one or more dibasic alcohols whose total molar amount is (m+1)x~(1.03m+1)x mol, A mixed solution A is obtained, wherein m is an integer from 1 to 20, and ...

Embodiment 1

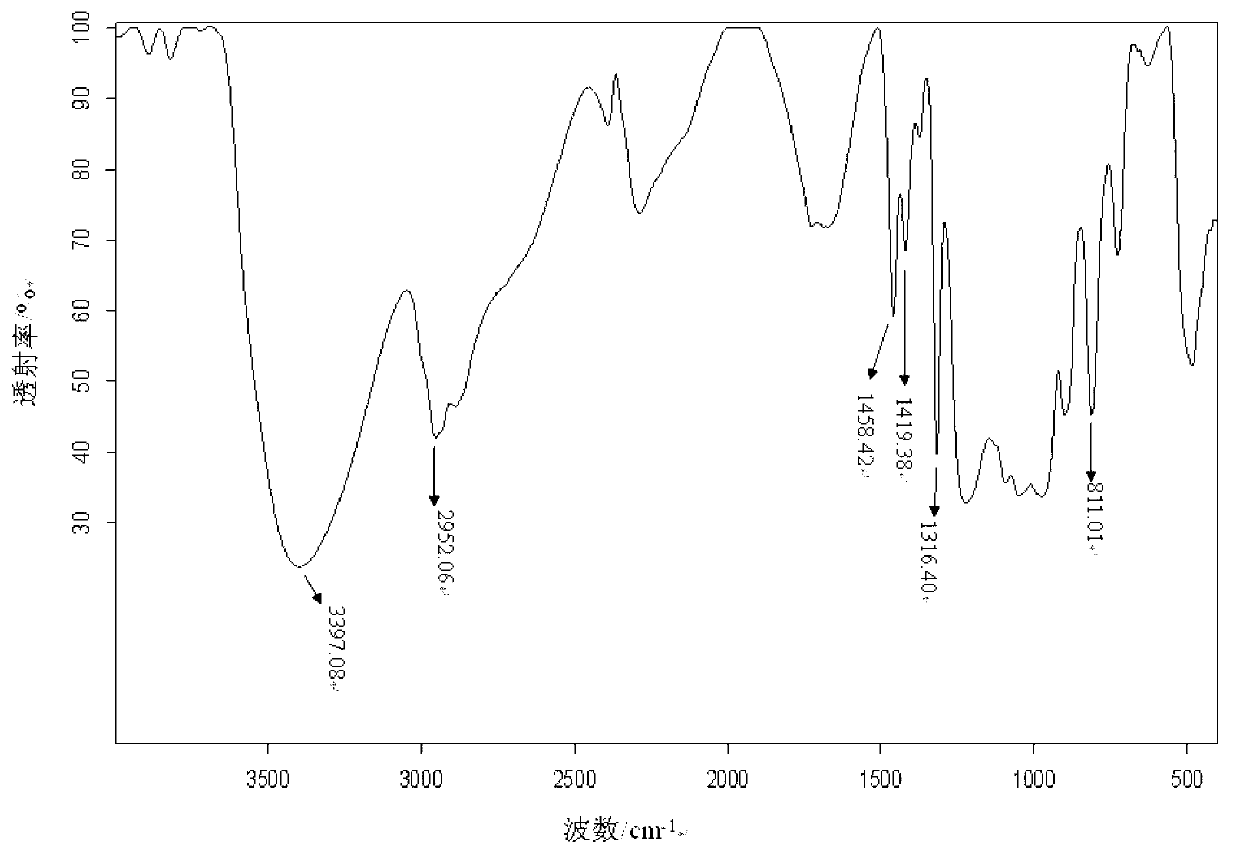

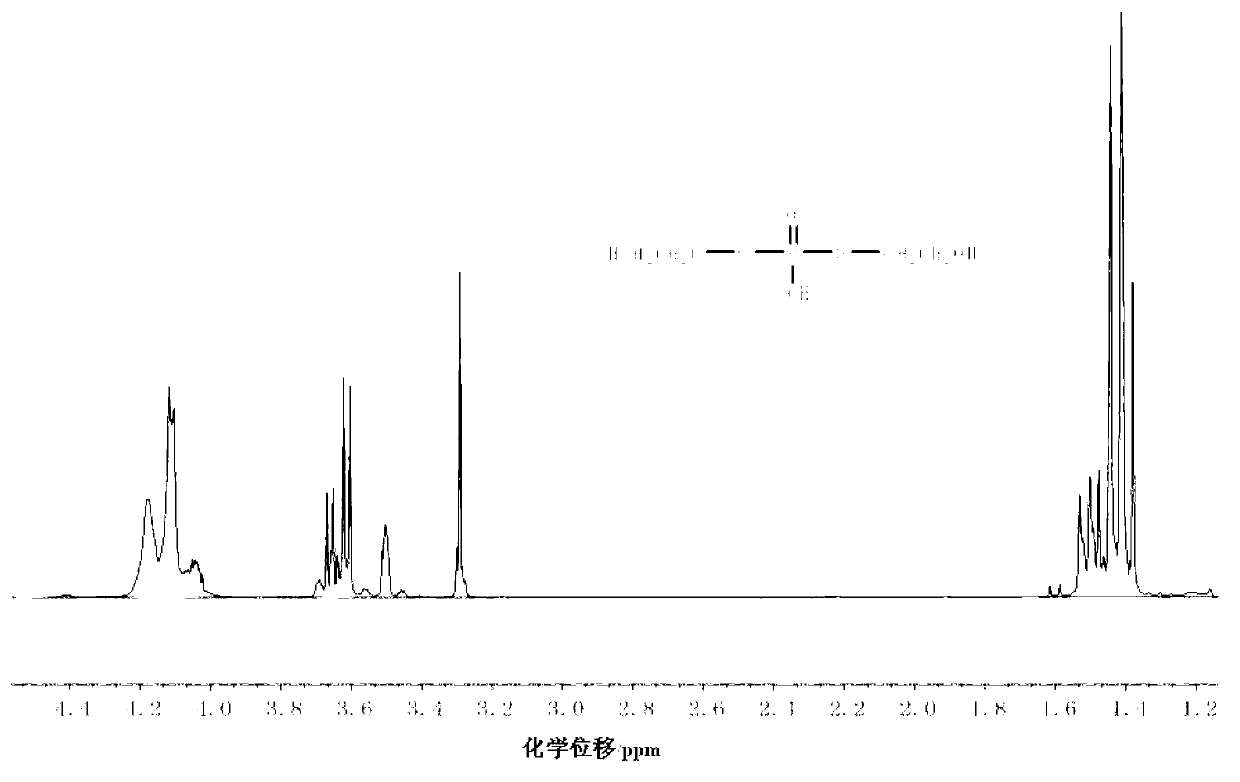

[0055] Preparation of Phosphorus-Containing Polyols

[0056] Preparation raw materials: 124g (1mol) of dimethyl methylphosphonate (boiling point: 181°C), 70g (1.13mol) of ethylene glycol (boiling point: 197.3°C), 0.4g (0.2wt of the total reactants) of dibutyltin dilaurate %) The theoretical hydroxyl value of the pre-prepared phosphorus-containing polyol is 87.5mgKOH / g. (At this time, in mx mol of dimethyl methylphosphonate and m+1)x~(1.03m+1)x mol of ethylene glycol, x=0.1, m=10, and ethylene glycol is in excess, The excess rate is 3% times the molar mass of dimethyl methylphosphonate)

[0057] Preparation method: Add dimethyl methylphosphonate, ethylene glycol, and dibutyltin dilaurate to a four-necked flask equipped with a stirrer, a thermometer, a nitrogen inlet, and a condenser, and stir evenly to form a mixed solution A, and pour it into a four-necked flask Nitrogen was introduced, and the mixed solution A was slowly heated to 180°C under the protection of nitrogen, and...

Embodiment 2

[0060] Preparation of phosphorus-containing polyols:

[0061] Raw materials: 166g (1mol) of diethyl ethylphosphonate (boiling point: 198°C), 94.5g (1.05mol) butanediol (boiling point: 228°C), 118g (boiling point: 253°C-260°C) hexanediol ( 1mol), 0.36g of cobalt acetate (0.1wt% of the total amount of reactants), and the theoretical hydroxyl value of the pre-prepared phosphorus-containing polyol is 30.5mgKOH / g after conversion. (At this time, in mx mol of diethyl ethyl phosphonate and (m+1)x~(1.03m+1)xmol of diol, x=1, m=1, and appropriate increase in diol The amount of butanediol, the ratio is 5% times the molar mass of diethyl ethyl phosphonate)

[0062] Preparation method: Add diethyl ethyl phosphonate, butanediol, hexanediol, and cobalt acetate to a four-necked flask equipped with a stirrer, a thermometer, a nitrogen inlet, and a condenser, and stir evenly to form a mixed solution A. Nitrogen gas was passed into the flask, and the mixed solution A was slowly heated to 140°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com