Material of elastic coupling for mining machinery and method for preparing material of elastic coupling for mining machinery

An elastic coupling and mechanical technology, applied in the direction of coating, etc., can solve the problems that are difficult to eliminate, the duration of antistatic performance is short, and the compatibility of thermoplastic polyurethane is not good, so as to prevent electrostatic discharge and improve antistatic performance and flame retardancy, the effect of reducing the likelihood and danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

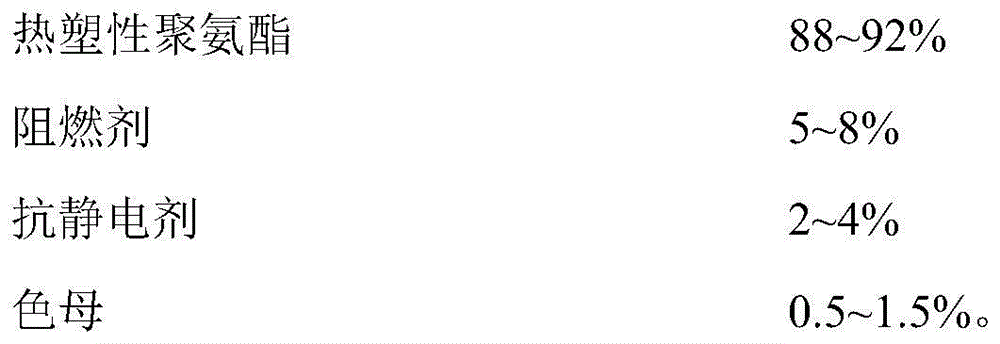

[0033] The material of an elastic coupling for mine machinery in this embodiment, its components and mass percentages are shown in Table 1.

[0034] Table 1 Embodiment 1 A kind of component and mass percentage content of the material of the elastic coupling of mine machinery

[0035] Raw material name

[0036] In this example, the thermoplastic polyurethane is ET90G provided by Shanghai Beiyue New Material Technology Co., Ltd., and its melting point is 172° C.; the flame retardant is HT-219 produced by Jinan Taixing Fine Chemical Co., Ltd., with P content ≥ 32%, N Content ≥ 7%, decomposition temperature ≥ 300 ℃; antistatic agent is E-1006 produced by Dongguan Fiat Electrostatic Technology Co., Ltd., surface resistance 10 7 ~10 8 Ω. Due to the different properties of different polymer masterbatches, their compatibility with different antistatic agents and flame retardants is different, and the types of antistatic agents and flame retardants that are suitable for the...

Embodiment 2

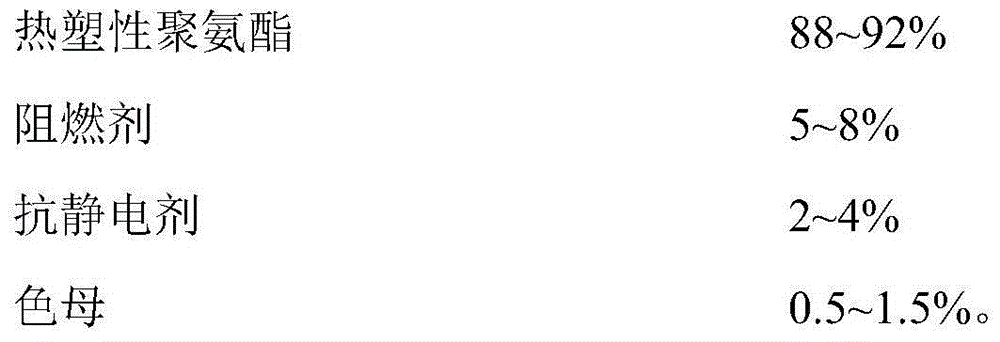

[0048] The material of an elastic coupling for mine machinery in this embodiment, its components and mass percentages are shown in Table 2.

[0049] Table 2 Embodiment 2 A material component and mass percentage content of an elastic coupling for mine machinery

[0050] Raw material name

Mass percentage %

90

flame retardant

6.5

3

black masterbatch

0.5

[0051] The manufacturers and performance parameters of each component in this implementation are the same as in Example 1, and the material formula of the above-mentioned elastic coupling of this example is adopted, and the steps of its preparation method are:

[0052] Step 1. Compounding agent premixing

[0053] Dry the unpacked thermoplastic polyurethane in an oven at 100°C for 3.5 hours, then put it together with flame retardant, antistatic agent, and color masterbatch in a high-speed mixer and stir for 100 seconds, so...

Embodiment 3

[0060] The material of an elastic coupling for mine machinery in this embodiment, its components and mass percentages are shown in Table 3.

[0061] Table 3 Embodiment 3 A material component and mass percentage content of a kind of elastic coupling for mine machinery

[0062] Raw material name

Mass percentage content%

92

flame retardant

5

antistatic agent

2

Yellow Masterbatch

1

[0063] The manufacturers and performance parameters of each component in this implementation are the same as in Example 1, and the material formula of the above-mentioned elastic coupling of this example is adopted, and the steps of its preparation method are:

[0064] Step 1. Compounding agent premixing

[0065] Dry the unpacked thermoplastic polyurethane in an oven at 110°C for 3 hours, then put it together with flame retardant, antistatic agent, and color masterbatch in a high-speed mixer and stir for 90 sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com