Antistatic shading PET film and preparation method thereof

An antistatic and film technology, applied in the field of antistatic light-shielding PET film and its preparation, can solve the problems of high cost and complicated preparation process, and achieve the effects of low cost, simple process and good light-shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

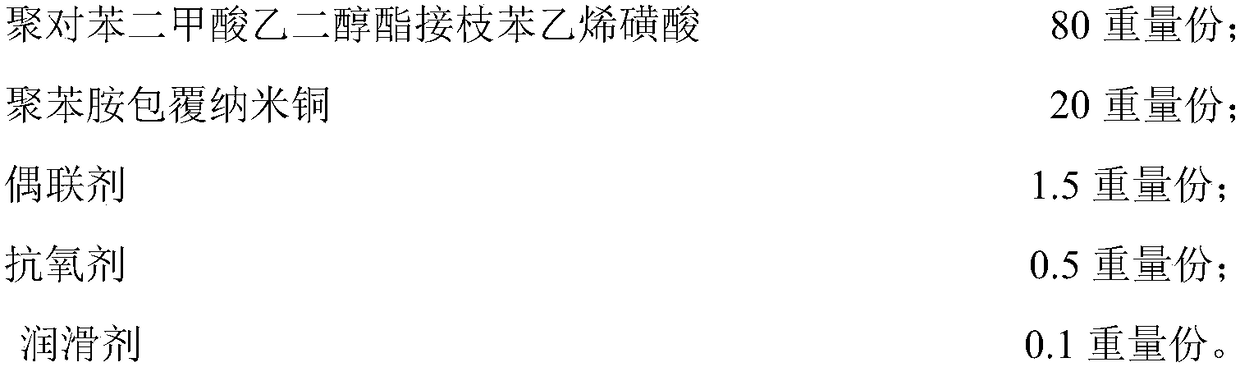

[0046]Correspondingly, the present invention also provides a preparation method of the antistatic light-shielding PET film described in the above technical solution, comprising the following steps: grafting polyethylene terephthalate to styrene sulfonic acid in a vacuum transfer system at 120°C Dried in a drum dryer for 12h, then polyaniline-coated nano-copper, coupling agent, antioxidant and lubricant were added to the side feed port of the twin-screw extruder, and polyethylene terephthalate grafted benzene Ethylene sulfonic acid is added through the main feeding port for melt blending, wire drawing and pelletizing, and melt extrusion to obtain a thick film. The thick film is biaxially stretched and shaped to obtain an antistatic and light-shielding PET film.

[0047] As can be seen from the above scheme, the present invention provides a kind of antistatic light-shielding PET film and preparation method thereof, with polyethylene terephthalate grafted styrene sulfonic acid, po...

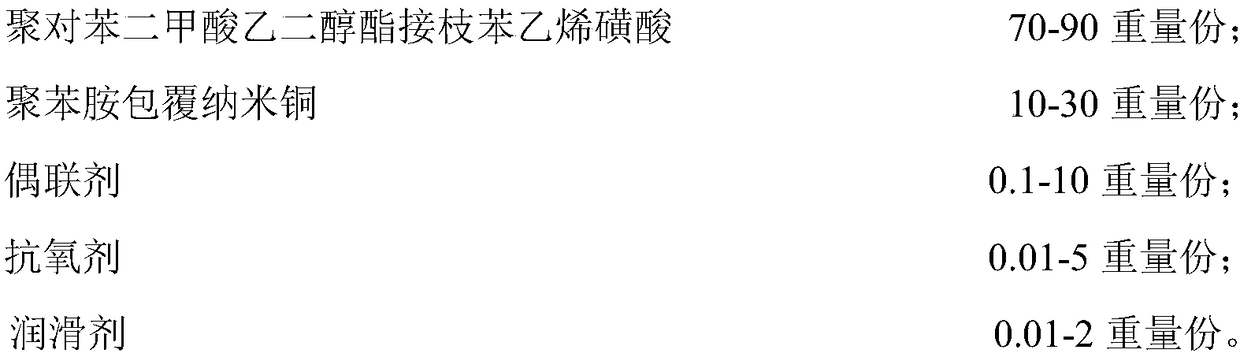

Embodiment 1

[0051] Feeding according to the ratio of parts by weight as described below

[0052] The PET film comprises the following components by weight:

[0053] 80 parts by weight of polyethylene terephthalate grafted styrene sulfonic acid;

[0054] 20 parts by weight of polyaniline-coated nano-copper;

[0055] 1.5 parts by weight of silane coupling agent;

[0056] Antioxidant 1098 0.5 parts by weight;

[0057] Lubricant 0.1 parts by weight.

[0058] Preparation steps:

[0059] Dry PET slices (polyethylene terephthalate grafted with styrene sulfonic acid) in a vacuum drum dryer at 120°C for 12 hours, and then coat nano-copper, silane coupling agent, and antioxidant with polyaniline 1098 and lubricant are added to the side feed port of the twin-screw extruder according to the above content, and PET is added through the main feed port for melt blending, drawing and pelletizing, and then returning to melt extrusion to obtain a thick film. Stretching and shaping to obtain antistatic...

Embodiment 2

[0063] Feeding according to the ratio of parts by weight as described below

[0064] The PET film comprises the following components by weight:

[0065] 80 parts by weight of polyethylene terephthalate;

[0066] 1.5 parts by weight of silane coupling agent;

[0067] Antioxidant 1098 0.5 parts by weight;

[0068] Lubricant 0.1 parts by weight.

[0069] Dry the PET chip (polyethylene terephthalate) in a vacuum drum dryer at 120°C for 12h, then coat the polyaniline with nano-copper, silane coupling agent, antioxidant 1098 and lubricant as above The content is added to the side feed port of the twin-screw extruder, PET is added through the main feed port, melted and blended, wire-drawn and pelletized, and then melted and extruded to obtain a thick film, which is shaped after two-way stretching Antistatic shading PET film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com