Oil-resistant anti-static-electricity rubber/EVA (ethylene-vinyl acetate copolymer) sole recipe as well as preparing method and application thereof

An antistatic agent and rubber technology, which is applied to the formulation of oil-resistant antistatic rubber/EVA sole and its preparation and application fields, can solve the problem of unstable antistatic function of sole, attenuation of antistatic agent effect, unfavorable EVA compound mixing and development. bubbles etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0149] Embodiment 1, prepare rubber outsole

[0150] 1) 30phr natural rubber and 70phr nitrile rubber are placed on a double-roller mill for mastication, and their plasticity is controlled between 0.4 and 0.45 to obtain masticated raw rubber;

[0151] 2) Put the masticated raw rubber obtained in step 1) into the internal mixer, and add 30phr carbon black N220, 15phr acetylene carbon black, 10phr antistatic agent, 8phr white oil, 10phr solid coumarone, and 5phr dibutyl fat , 10phr zinc oxide, 1phr stearic acid, 1phr accelerator DM, 1phr accelerator CZ, 1phr antioxidant 4010, 0.8phr antioxidant RD, mixing evenly and controlling the plasticity of the mixed rubber between 0.25 and 0.32, obtained Mixed rubber, parked for 24 hours for use;

[0152] 3) Put the mixed rubber obtained in step 2) on a double-roller mill for re-milling, add 2.5phr sulfur and 0.02phr accelerator TMTD at the same time, and then thin pass 4 times before use; weigh the rubber material and put it in a 165°C ...

Embodiment 2

[0154] Embodiment 2, prepare rubber outsole

[0155] 1) 40phr natural rubber and 60phr nitrile rubber are placed on a double-roller mill for mastication, and its plasticity is controlled between 0.4 and 0.45 to obtain masticated raw rubber;

[0156] 2) Put the masticated raw rubber obtained in step 1) into an internal mixer, and add 40phr carbon black N220, 10phr acetylene carbon black, 12phr antistatic agent, 10phr white oil, 10phr solid coumarone, 8phr dibutyl fat, 10phr Zinc Oxide, 1.5phr Stearic Acid, 1.5phr Accelerator DM, 0.5phr Accelerator CZ, 1.5phr Antiaging Agent 4010, 0.5phr Antiaging Agent RD, mix evenly and control the plasticity of the mixed rubber between 0.25 and 0.32 During the period, the obtained mixed rubber was parked for 24 hours for use;

[0157] 3) Put the mixed rubber obtained in step 2) on a double-roller mill for re-milling, add 2phr sulfur and 0.05phr accelerator TMTD at the same time, and then thin pass 4 times before use; weigh the rubber and put...

Embodiment 3

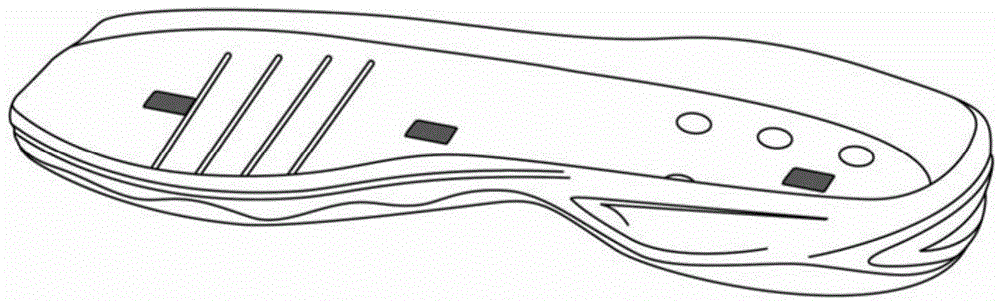

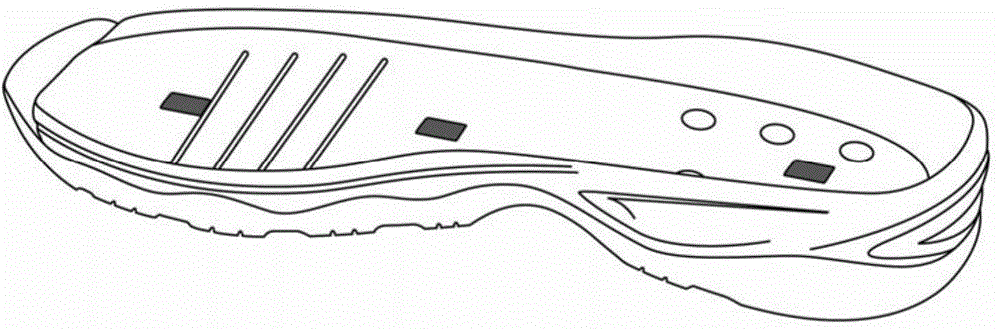

[0161] Embodiment 3, prepare foaming EVA at the end

[0162] 70phr number average molecular weight is 18000 ethylene-vinyl acetate copolymer EVA, 15phr EPDM, 15phr number average molecular weight is 43000 POE 8180, 15phr talcum powder RB-510, 5phr blowing agent AC, 0.5phr dicumyl peroxide , 2phr zinc oxide, 1phr stearic acid, 2.5phr titanium dioxide, and 10phr color masterbatch filler are put into the internal mixer to fully banbury, and then granulate; weigh EVA granules and put them into the mold for one-time foaming to form EVA foam For the embryo, the magnification is controlled between 1.4 and 1.5 times; three copper sheets with a size of 50mm×10mm×0.1mm penetrate the forefoot, waist and heel of the EVA embryo respectively, and the two ends are flattened and put into the secondary molding High-temperature molding in the mold, the temperature is 175°C, the time is 10 minutes, and the antistatic foaming EVA midsole is obtained after water cooling.

[0163] The physical pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com