High-strength, flame-retardant and antistatic polyolefin pipeline and preparation method thereof

An anti-static, polyolefin technology, applied in the field of construction engineering, can solve the problems of poor anti-static ability, low strength of plastic pipes, poor flame retardancy, etc., to achieve good interface bonding, improve compatibility, and simplify the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

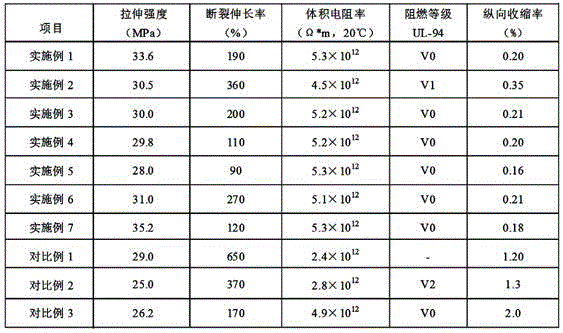

Examples

Embodiment 1

[0028] (1) Weigh raw materials: polyethylene 72kg, maleic anhydride 1.4kg, styrene 1.4kg, benzoyl peroxide 0.02kg, 2mm short glass fiber 10kg, silane coupling agent KH550 0.2kg, red phosphorus 8kg, carbon Black 8kg, compound antioxidant 10100.25kg and triphenyl phosphite 0.25kg;

[0029] (2) Immerse short glass fibers in an aqueous solution of silane coupling agent KH550 with a mass ratio concentration of 2% for 10 minutes; dry the soaked short glass fibers at a temperature of 85°C for 30 minutes, and then heat up to 130°C Under reaction 30min, the short glass fiber that gets surface treatment;

[0030] (3) Mix red phosphorus, carbon black and 14.4kg polyethylene, mix for 3 minutes at the speed of high mixer 800r / min, then increase the speed to 2000r / min and mix for 5 minutes, and add the mixed materials to the same direction meshing In the twin-screw extruder, set the temperature of the feeding section of the twin-screw extruder to 140°C; the temperature of the melting secti...

Embodiment 2

[0034](1) Weigh raw materials: polyethylene 80kg, maleic anhydride 1.6kg, styrene 1.6kg, benzoyl peroxide 0.02kg, 2mm short glass fiber 6kg, silane coupling agent KH550 0.12kg, red phosphorus 6kg, carbon Black 6kg, compound antioxidant 10100.25kg and triphenyl phosphite 0.25kg;

[0035] (2) Immerse short glass fibers in an aqueous solution of silane coupling agent KH550 with a mass ratio concentration of 2% for 10 minutes; dry the soaked short glass fibers at a temperature of 85°C for 30 minutes, and then heat up to 130°C Under reaction 30min, the short glass fiber that gets surface treatment;

[0036] (3) Mix red phosphorus, carbon black and 16kg of polyethylene, mix for 3 minutes at the speed of high mixer 800r / min, then increase the speed to 2000r / min and mix for 5 minutes, and add the mixed materials to the same direction meshing In the twin-screw extruder, set the temperature of the feeding section of the twin-screw extruder to 140°C; the temperature of the melting secti...

Embodiment 3

[0040] (1) Weigh raw materials: polyethylene 76kg, maleic anhydride 1.5kg, styrene 1.5kg, benzoyl peroxide 0.02kg, 2mm short glass fiber 6kg, silane coupling agent KH550 0.12kg, red phosphorus 8kg, carbon Black 8kg, compound antioxidant 10100.25kg and triphenyl phosphite 0.25kg;

[0041] (2) Immerse short glass fibers in an aqueous solution of silane coupling agent KH550 with a mass ratio concentration of 1% for 10 minutes; dry the soaked short glass fibers at a temperature of 85°C for 30 minutes, and then raise the temperature to 130°C Under reaction 30min, the short glass fiber that gets surface treatment;

[0042] (3) Mix red phosphorus, carbon black and 19kg polyethylene, mix for 3 minutes at the speed of high mixer 800r / min, then increase the speed to 2000r / min and mix for 5 minutes, and add the mixed materials to the co-meshing double In the screw extruder, the temperature of the feeding section of the twin-screw extruder is set to 140°C; the temperature of the melting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com