Manufacturing method of compound material supporting plate

A composite material and manufacturing method technology, used in earth-moving drilling, installation of bolts, mining equipment, etc., can solve the problems of low strength, complex manufacturing process and high cost, and achieve simple manufacturing process, high product strength, and low antistatic. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

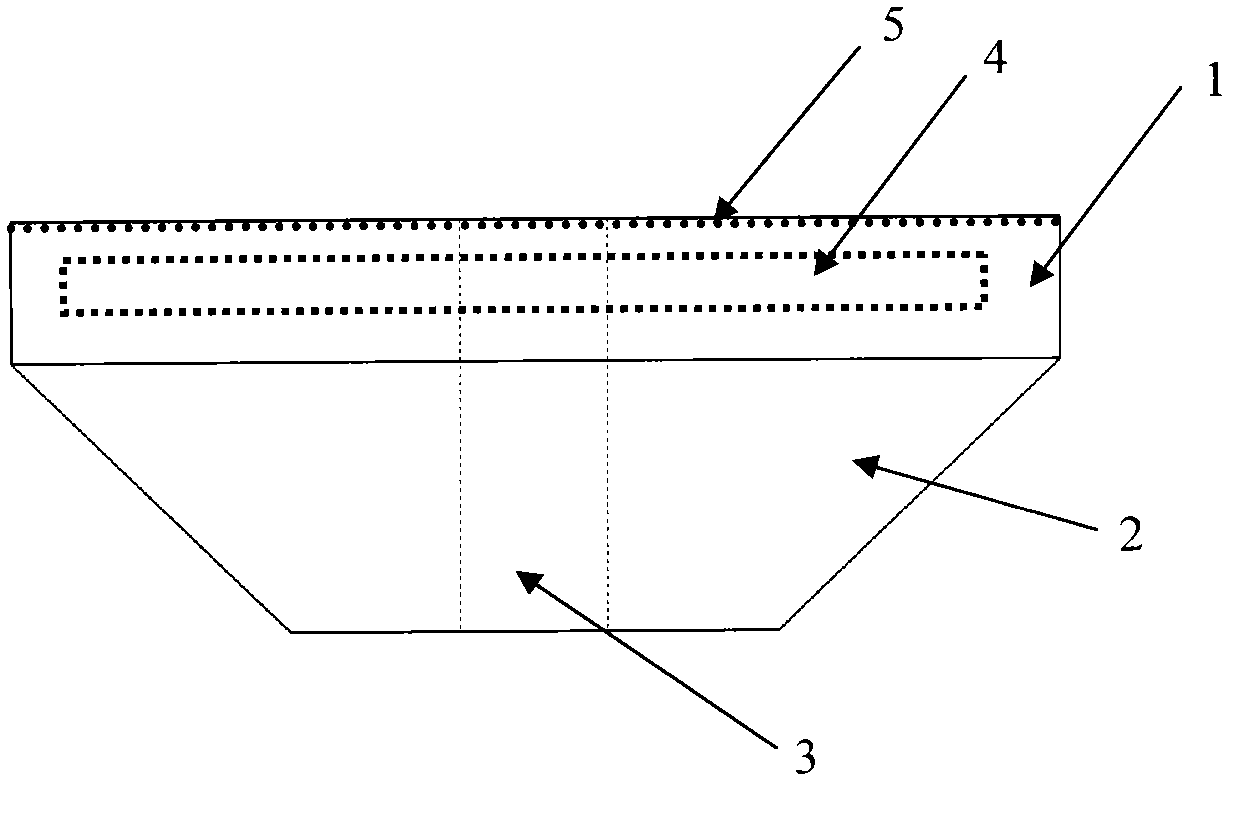

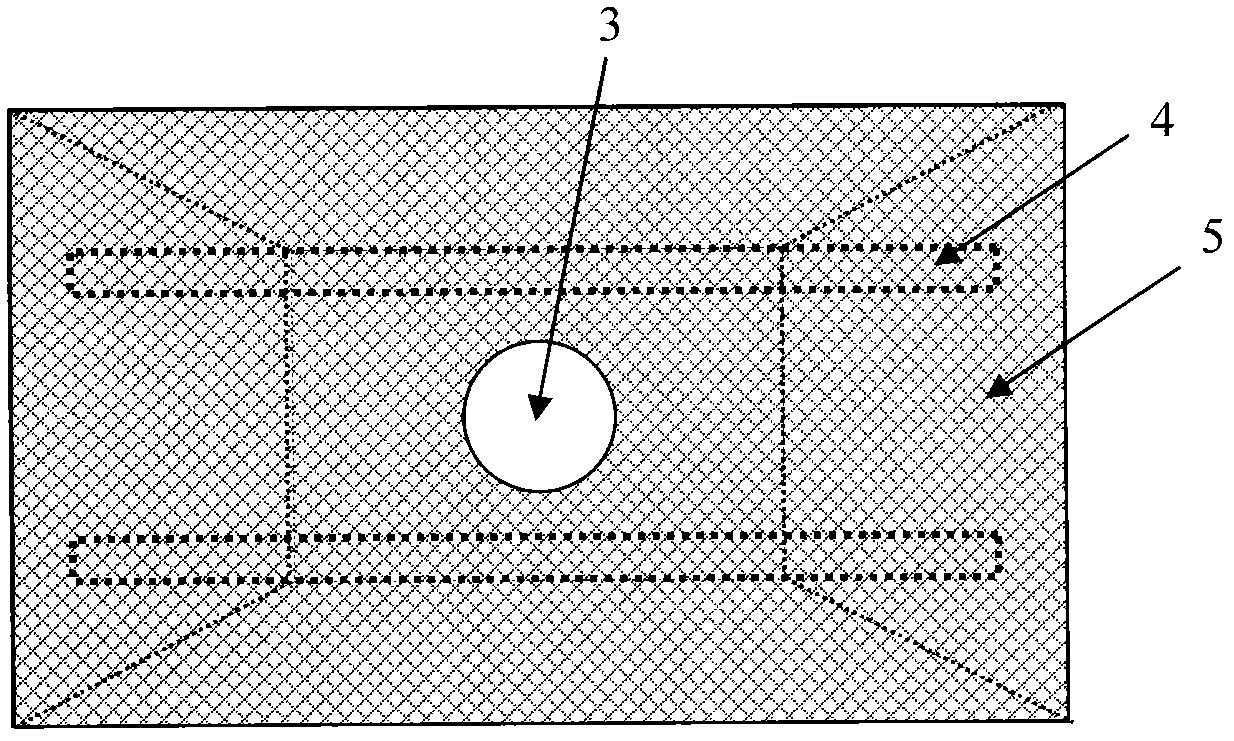

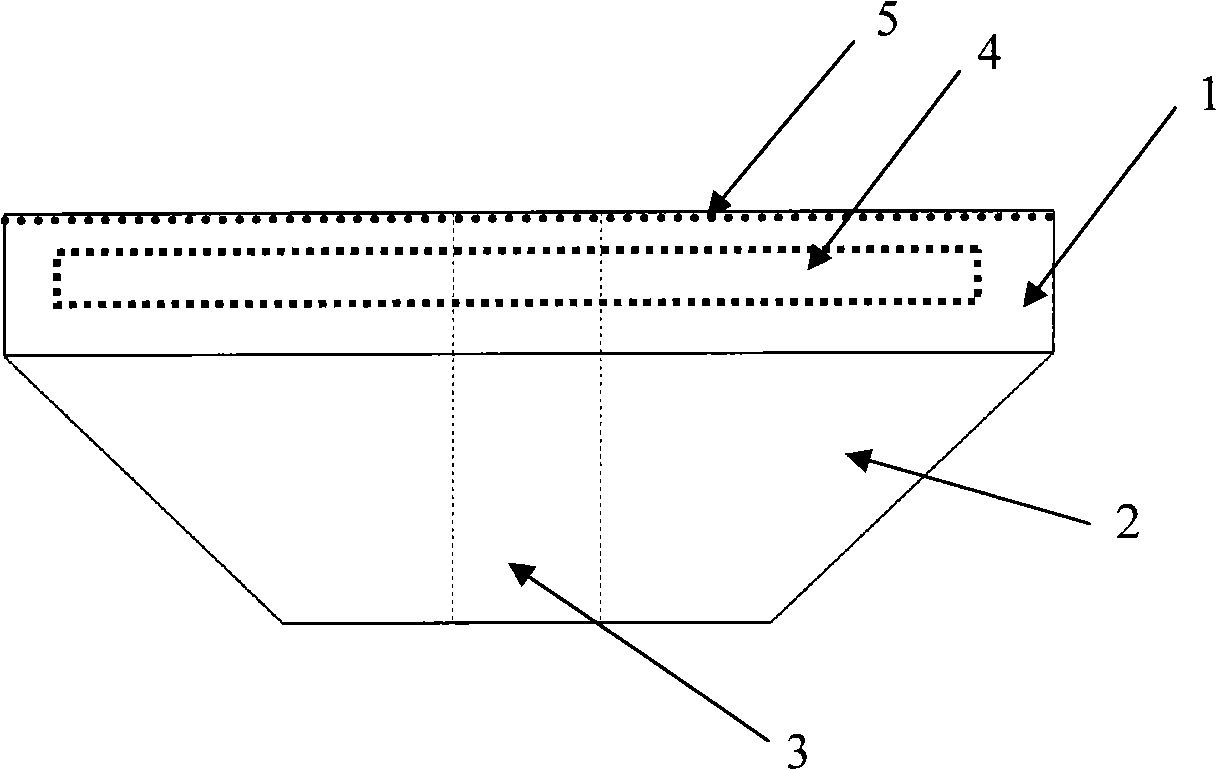

[0017] A method for manufacturing a composite support pallet, the process steps of which are:

[0018] (1) the alkali-free glass fiber roving that mass percent is 40%, is equipped with 45% 191# unsaturated polyester resin, 3% benzoyl peroxide, 3% dibenzoyl peroxide- Tertiary amine, 4% BYK-A5554 defoamer, 5% calcium hydroxide, fully stirred with a mixer;

[0019] (2) Pack the stirred material into the die;

[0020] (3) Mold closing, pressurization and heat preservation, pressure 30MPa, temperature 120°C, pressure holding time 3 minutes;

[0021] (4) Open the mold and eject the composite support pallet.

[0022] A method for manufacturing a composite support pallet, the process steps of which are:

[0023] (1) the alkali-free glass fiber roving that mass percent is 55%, is equipped with 30% 191# unsaturated polyester resin, 2% benzoyl peroxide, 1% dibenzoyl peroxide- Tertiary amine, 6% BYK-A5554 defoamer, 6% calcium hydroxide, fully stirred with a mixer;

[0024] (2) packin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com