TPE flame resistant material for coating plastic and preparing method of TPE flame resistant material

A technology of flame retardant materials and plastic bags, applied in the field of TPE flame retardant materials and their preparation, to achieve the effects of lower processing temperature, energy saving, and elimination of easy precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

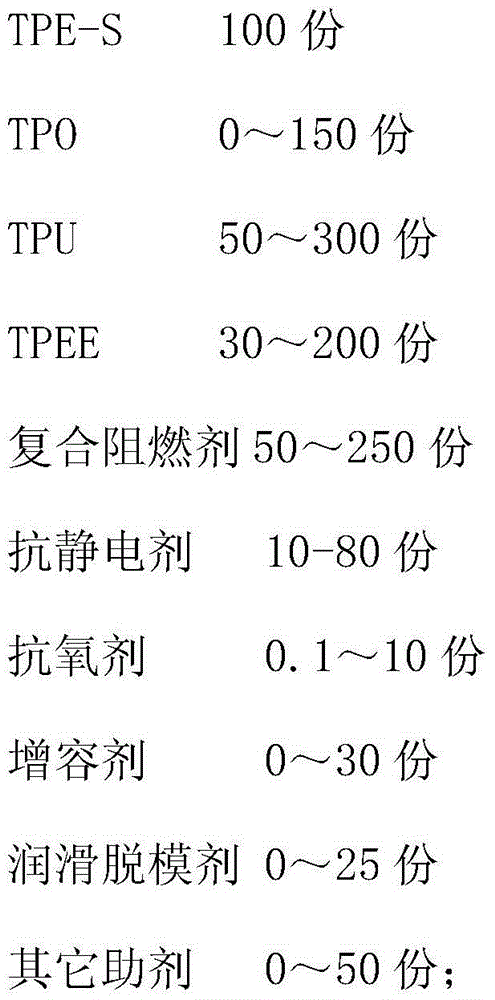

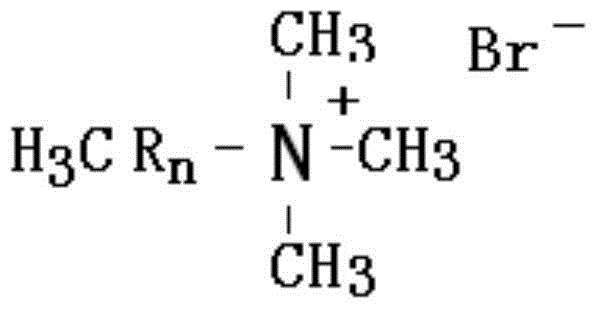

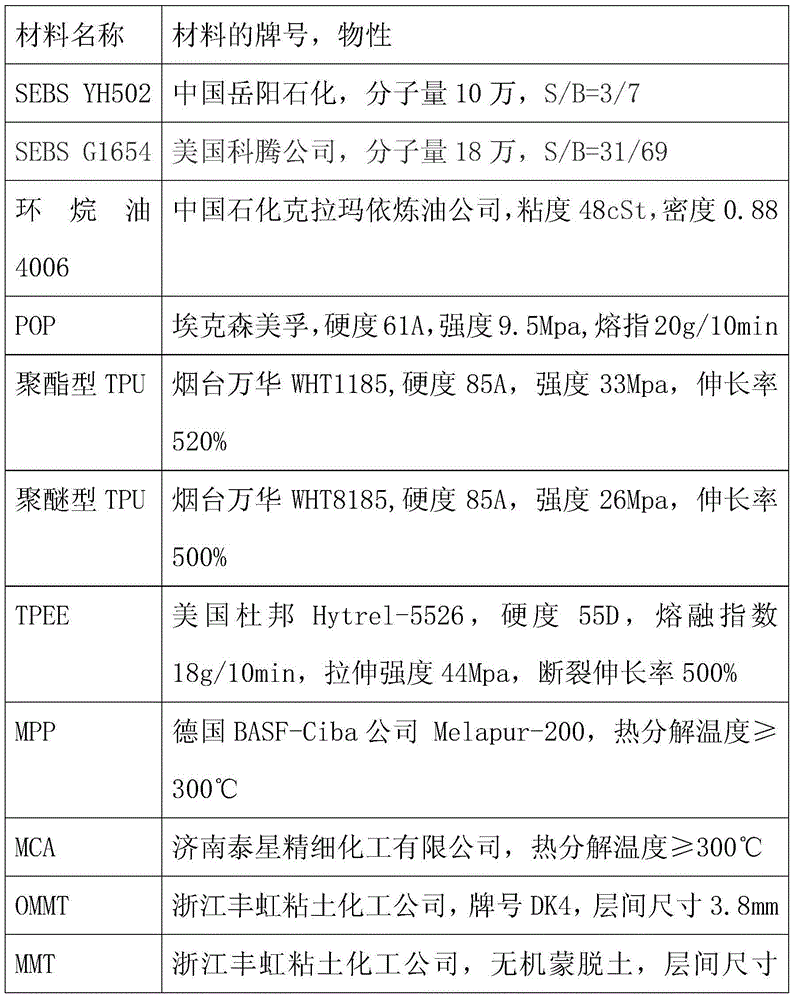

Method used

Image

Examples

Embodiment 1

[0045] Example 1: Use 4006# naphthenic oil to premix SEBS-YH502 and SEBS-G1654 as TPE-S, and form the base material with TPU-WHT1185 and TPEE-5526, and use MPP, MCA and OMMT to form a composite flame retardant. Ciba’s P20 is an antistatic agent, and other components are detailed in Example 1 of Table 2. From the test results of Example 1 in Table 3, it can be seen that the prepared TPE composite material is soft and has good mechanical properties. Up to 8.7N / mm, strong adhesion; the test hardness is Shore 86A, the tensile strength is 15.5Mpa, and the elongation at break is 355%; UL94 vertical combustion reaches V-0 level, excellent flame retardant performance, high temperature and high humidity Test: no precipitation; good aging resistance, permanent compression deformation rate is only 28%, surface resistivity is 5.6×10 10 , and good washing resistance, after washing 100 times, it is still 5.3×10 10 ;The surface of the material is smooth and matte, with good wear resistance ...

Embodiment 2

[0046] Example 2: 4006# naphthenic oil was used to premix SEBS-YH502, only SEBS-G1654 was removed, and other components were equal to Example 1. The test results of Example 2 in Table 3: Compared with Example 1, the melt index of the prepared TPE coating material increased slightly, from the original 8.4g / 10min to 9.3g / 10min, and the UL94 flame retardancy was V-0 , Peel strength 8.2N / mm, excellent overall performance.

Embodiment 3

[0047] Example 3: 4006# naphthenic oil was used to premix SEBS-G1654, only SEBS-YH502 was removed, and other components were equal to Example 1. The test results of Example 3 in Table 3: Compared with Example 1 and Example 2, the physical properties of the prepared TPE coating material are basically unchanged, and the overall performance meets the requirements for the use of environmentally friendly TPE flame retardant materials for coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com