Super-hydrophobic flame-retardant anti-cutting stab-resistant fabric and production method thereof

A production method and technology for flame retardant fabrics, applied in chemical instruments and methods, filament generation, layered products, etc., can solve the problems of poor water resistance and air permeability, affecting the scope of use, etc., achieve easy flying, avoid candle wick effect, good The effect of flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

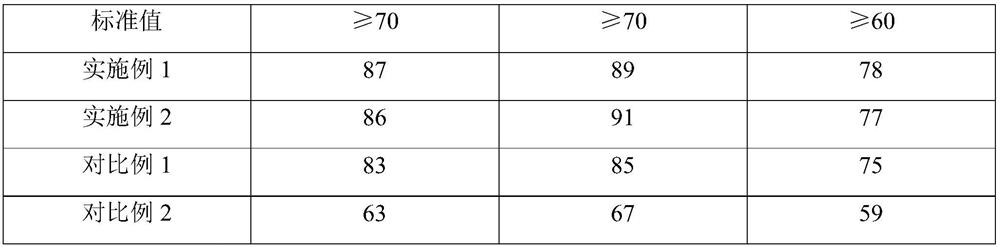

Embodiment 1

[0038] A superhydrophobic, flame-retardant, cut-proof and stab-resistant fabric, comprising an antibacterial and thermal fabric layer and a hydrophobic and flame-retardant fabric layer arranged on the outside of the antibacterial and thermal fabric layer; Fiber and antibacterial polyester fiber are mixed and woven according to the mass fraction ratio of 6:3:1, and the hydrophobic and flame-retardant fabric layer is made of ultra-high molecular weight polyethylene curly staple fiber, cotton fiber and glass fiber according to the mass fraction ratio of 5:3: 1 Mixed weaving, wherein ultra-high molecular weight polyethylene curly short fibers and glass fibers are soaked in a hydrophobic solution with a dipping bath ratio of 1:30 before weaving and dried, and the hydrophobic solution is composed of the following substances in weight percentage: ammonium polyphosphate 20% , SiO 2 8% solution, 8% silane coupling agent, 10% modified polyethylene wax, 20% vinyl acetate-methylol acrylam...

Embodiment 2

[0051] A superhydrophobic, flame-retardant, cut-proof and stab-resistant fabric, comprising an antibacterial and thermal fabric layer and a hydrophobic and flame-retardant fabric layer arranged on the outside of the antibacterial and thermal fabric layer; Fiber and antibacterial polyester fiber are mixed and woven according to the mass fraction ratio of 6:3:1, and the hydrophobic and flame-retardant fabric layer is made of ultra-high molecular weight polyethylene curly staple fiber, cotton fiber and glass fiber according to the mass fraction ratio of 5:3: 1 Mixed weaving, wherein ultra-high molecular weight polyethylene curly short fibers and glass fibers are soaked in a hydrophobic solution with a dipping bath ratio of 1:30 before weaving and dried, and the hydrophobic solution is composed of the following substances in weight percentage: ammonium polyphosphate 20% , SiO 2 8% solution, 8% silane coupling agent, 10% modified polyethylene wax, 20% vinyl acetate-methylol acrylam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com