Method for growing LED epitaxial structure

A technology of epitaxial structure and growth method, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of reducing the anti-aging ability and anti-static ability of LED devices, reducing the optical output power of LED devices, and increasing leakage channels of LED devices. Achieve the effect of improving lattice mismatch, protecting crystal ordering, and improving bottom warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

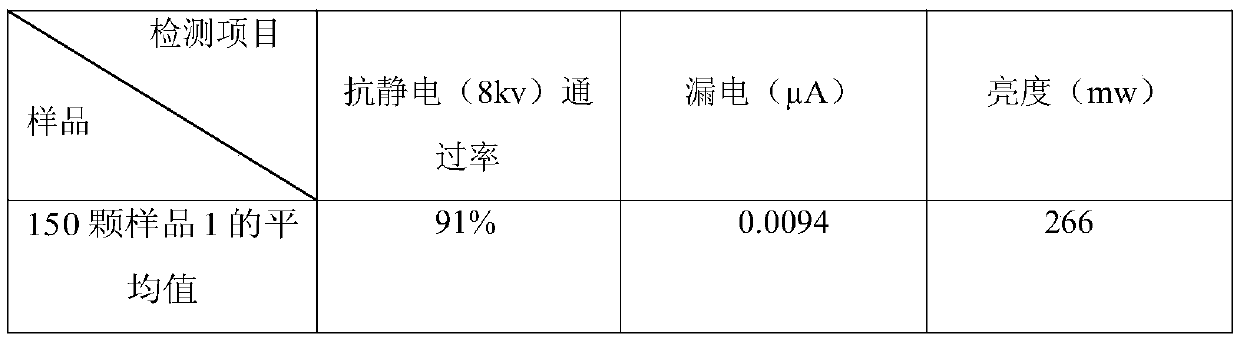

Embodiment 1

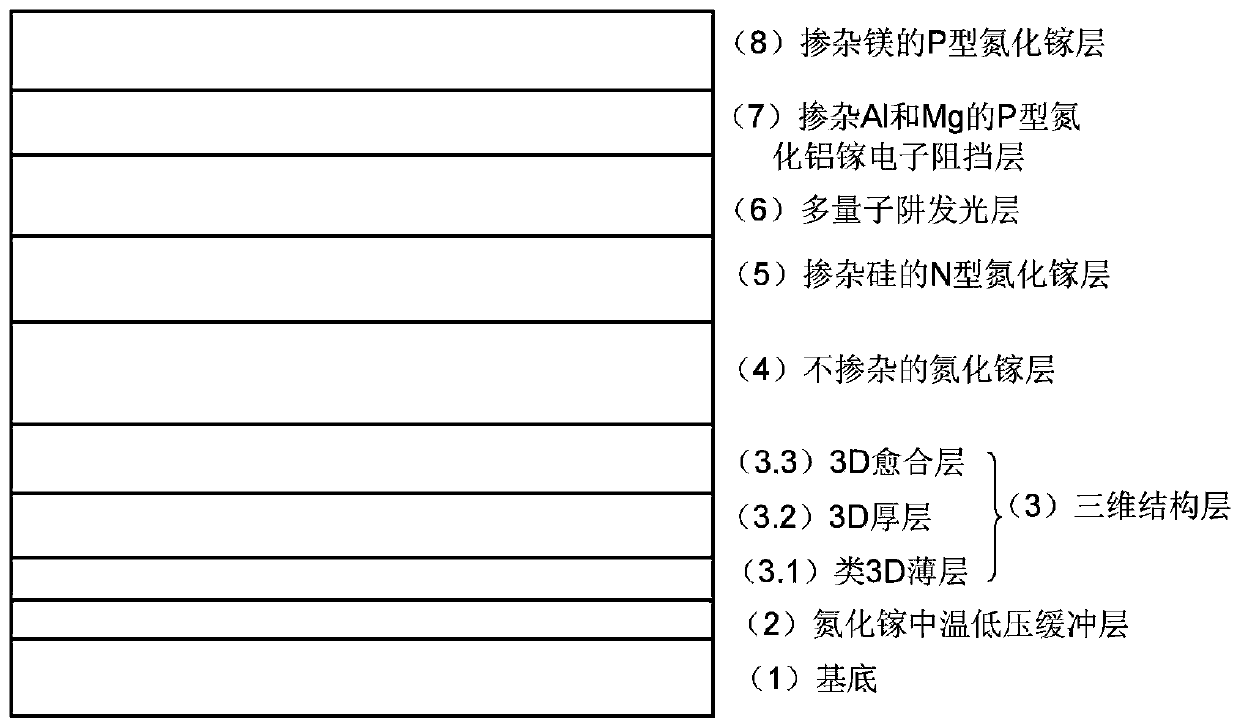

[0037] A method for growing an LED epitaxial structure, including the process of growing a gallium nitride medium-temperature and low-pressure buffer layer and a three-dimensional structure layer, specifically:

[0038] Step 2: growing GaN medium temperature and low pressure buffer layer;

[0039] Step 3: growing a three-dimensional structure layer;

[0040] The three-dimensional structural layer includes a 3D-like thin layer, a 3D thick layer and a 3D healing layer grown sequentially from bottom to top.

[0041] The step 2 is specifically: control the temperature of the reaction chamber at 800° C., the pressure at 100 mbar, feed ammonia gas with a flow rate of 35 L / min and trimethylgallium with a flow rate of 65 sccm, and grow a thickness of 20nm gallium nitride medium temperature and low pressure buffer layer.

[0042] The step 3: growing a three-dimensional structure layer includes the following steps:

[0043] Step 3.1: grow a 3D-like thin layer, specifically, control t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com