Antistatic spinning oil agent and preparation method thereof

A technology of spinning oil and antistatic agent, which is applied in the field of antistatic spinning oil and its preparation, can solve the problems such as the corrosion of equipment by the spinning oil, reduce surface tension, improve stability, reduce fluff and The effect of broken yarn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides an antistatic spinning finish, which is composed of a smoothing agent, an emulsifying dispersant, a sizing agent, an antistatic agent and a function regulator, and the weight percentage of the smoothing agent in the spinning finish is 80-88% %, the weight percent of the emulsifying dispersant in the spinning finish is 3-6%, the weight percent of the sizing agent in the spinning finish is 4-8%, and the weight percent of the antistatic agent in the spinning finish is 3-6%, the percentage by weight of the functional regulator in the spinning oil is 1-5%; the antistatic agent is composed of fatty alcohol polyoxyethylene ether phosphate and superfine antistatic powder, and the fatty alcohol polyoxyethylene The weight percentage of ether phosphate ester salt and ultrafine antistatic powder is 1:0.5~1.5, and the antistatic agent adopts anionic surfactant, which can prevent the antistatic agent from corroding the instrument during the production process;...

Embodiment 2

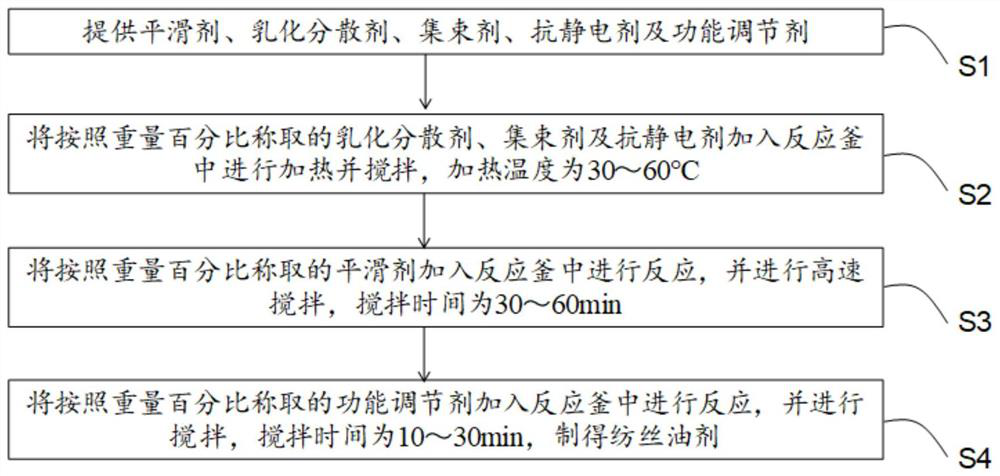

[0038] see figure 1As shown, based on the same inventive concept, this embodiment provides a method for preparing an antistatic spinning finish, comprising the following steps:

[0039] S1: Provide smoothing agent, emulsifying dispersant, sizing agent, antistatic agent and functional regulator, and the weight percentage of smoothing agent in spinning finish is 80-88%, the weight of emulsifying dispersing agent in spinning finish The percentage is 3-6%, the weight percentage of the sizing agent in the spinning finish is 4-8%, the weight percentage of the antistatic agent in the spinning finish is 3-6%, and the function regulator is in the spinning finish The weight percentage in is 1~5%;

[0040] In this example, the antistatic agent is composed of fatty alcohol polyoxyethylene ether phosphate ester salt and ultrafine antistatic powder, and the weight percentage of fatty alcohol polyoxyethylene ether phosphate ester salt and ultrafine antistatic powder is 1:0.5 ~1.5, the anti...

Embodiment 3

[0045] The present embodiment provides a kind of preparation method of antistatic type spinning finish, comprises the following steps:

[0046] S1: Provide smoothing agent, emulsifying and dispersing agent, sizing agent, antistatic agent and functional regulator;

[0047] The smoothing agent selects weight percent as 40% aliphatic alcohol (C 10-12) block polyether (MV is 2000) and adds weight percent as the methyl end n-butyl polyether (MV=1500) that adds weight percent as 21% combination of propylene glycol random polyether (MV is 2500); the emulsifying dispersant adopts 3% by weight of octyl polyoxyethylene polyoxypropylene ether (MV is 3000) plus 1% by weight of lauryl polyether The combination of oxyethylene (8) ether; the combination of 2% N-lauroyl glutamic acid dodecylamine salt that the weight percentage is 4% glycerol random polyether (MV is 6000) for sizing agent; The electrostatic agent is a combination of 3% octyl polyoxyethylene ether phosphate potassium salt plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com