Compact spinning apparatus of spinning frame

A spinning frame, compact technology, applied in the direction of spinning machines, textiles, papermaking, drafting equipment, etc., can solve the problems of "hairiness" and achieve the effects of reduced turn-up angle, less yarn breakage and easy twist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

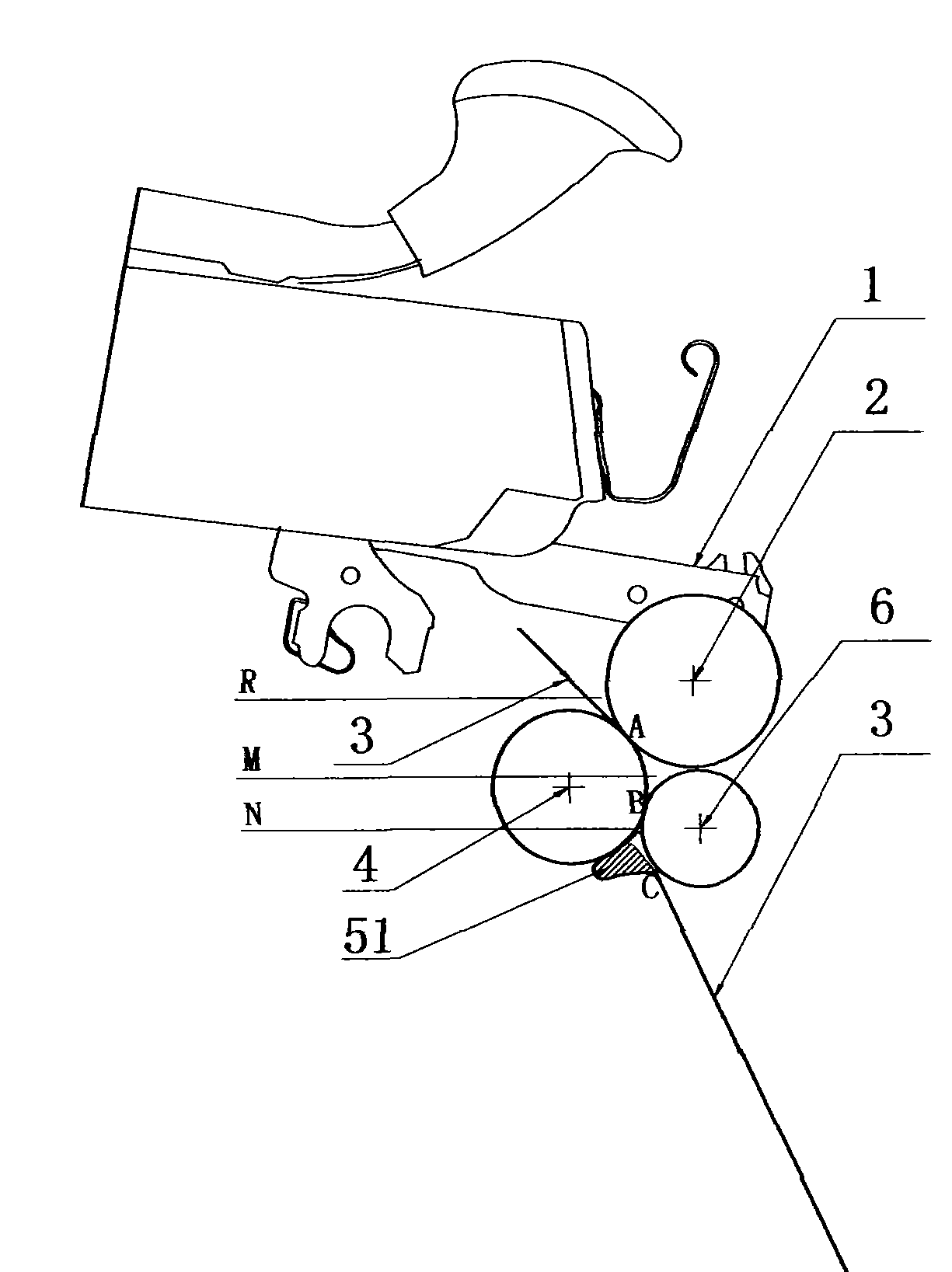

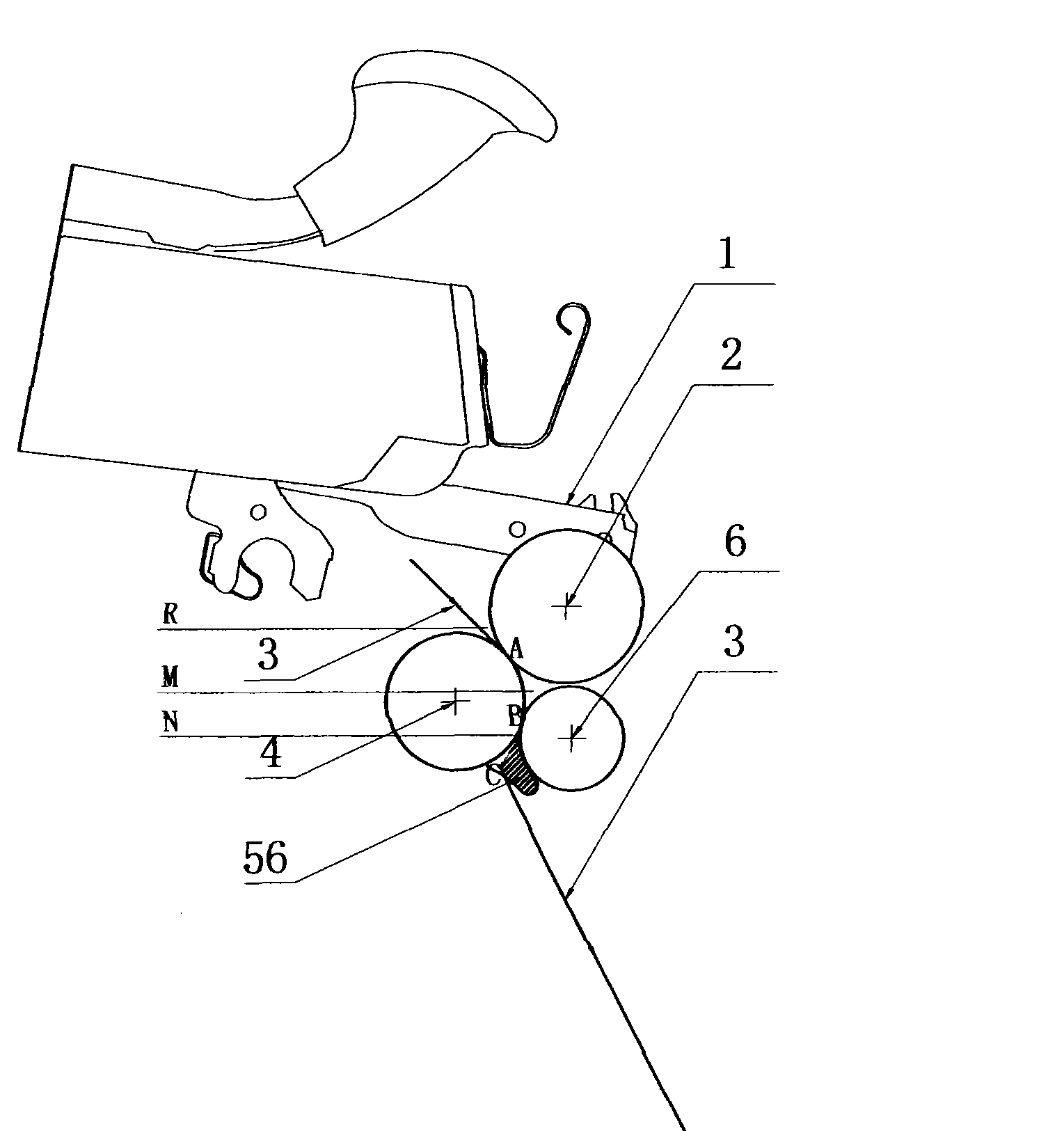

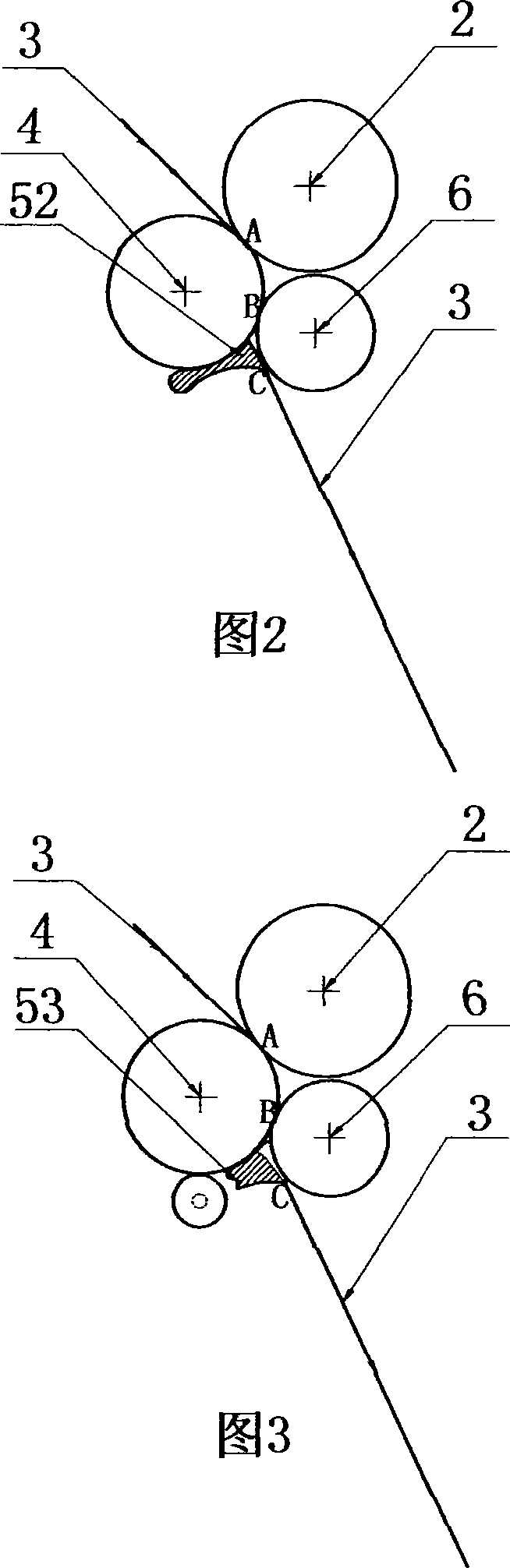

[0025] like figure 1 As shown, the bottom roller 2 is installed on the cradle 1 of the spinning frame, and the bottom roller 4 is installed under the cradle 1 and pressed tightly on the bottom roller 2. A pair of bottom roller 2 and bottom roller 4 are formed. The drafting pressure roller drafts the yarn 3, the output pressure roller 6 is pressed against the bottom roller 4, and the converging member 5 is installed in the converging area N.

[0026] The contact area A formed between the bottom roller 4 and the bottom top roller 2 constitutes a drafting area R between the pre-drafting device and the output end A of the draft pressure roller composed of the bottom roller 4 and the bottom top roller 2; The contact area B formed by the bottom roller 4 and the output pressure roller 6, the yarn guide area M is formed between the output end A of the drafting zone R and the output end B of the bottom roller 4 and the output pressure roller 6, extending from the output end B A bundle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com