Yarn winding adjustment device applied to weft accumulator

A technology of adjusting device and weft accumulator, which is applied to auxiliary equipment for weaving, textile, textile and paper making, etc., can solve the problems of weft thread falling off, reducing the amount of yarn that can be stored in the storage drum, etc., so as to achieve less friction damage and reduce yarn breakage. The probability of occurrence, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

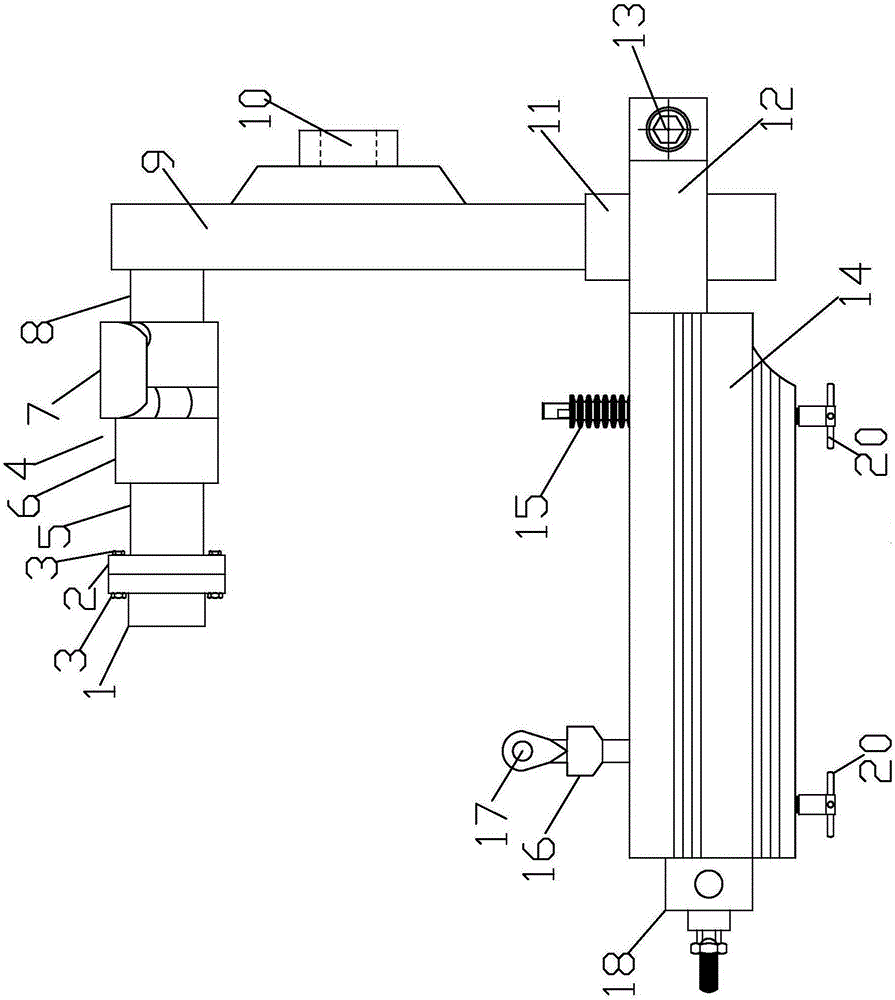

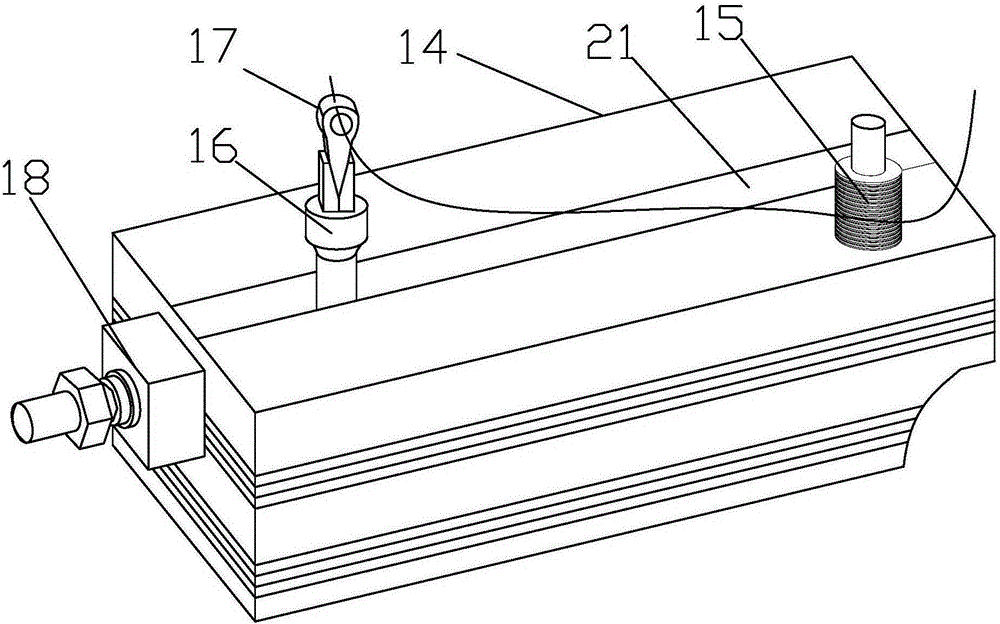

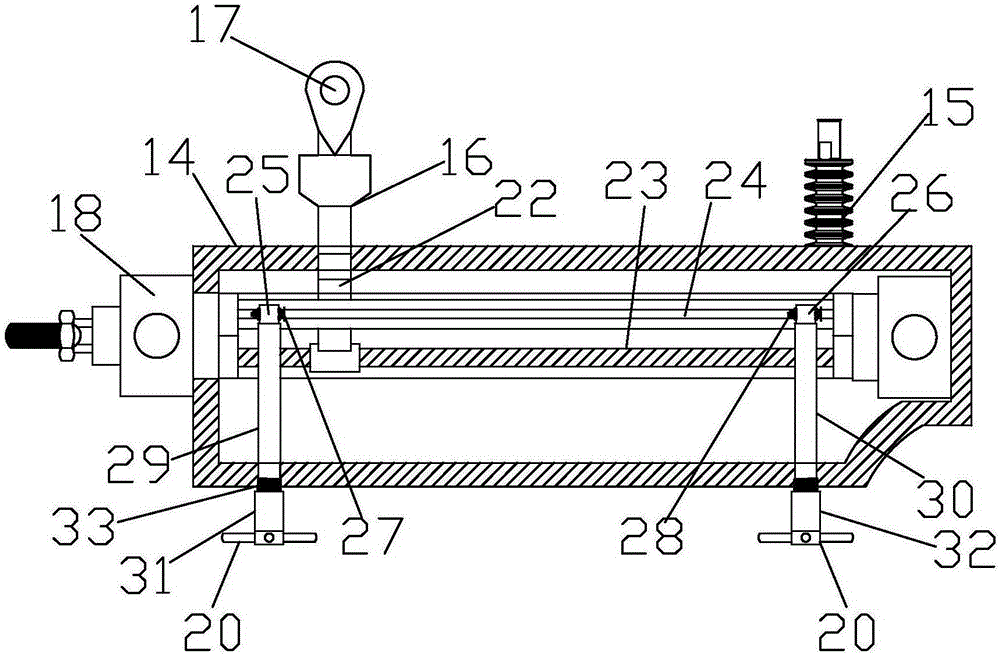

[0036] Such as Figure 1 to Figure 10 As shown, a yarn winding adjustment device applied to a weft feeder includes an installation mechanism and an adjustment mechanism, and the installation mechanism is used to install the present invention on the casing 39 of the weft feeder 40 . The installation mechanism includes an electromagnet sucker 1, a telescopic rod 4 and a yarn feeding disc 9. The left end of the telescopic rod 4 is connected to the electromagnet sucker 1, the right end of the telescopic rod 4 is connected to the yarn feeding disc 9, and the electromagnet sucker 1 and the telescopic rod 4 are connected. There is a flange 2, and the flange 2 and the base of the electromagnet chuck 1 are provided with screw holes (not marked in the figure), and the bolt 3 is connected in the two screw holes, and then the electromagnet chuck 1 and the telescopic pole 4. The flange 2 is used for connection, not only is the connection firm, but also has a detachable function, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com