Online lower taking vertical stacking system of float glass

A float glass and stacking technology, which is applied in the field of glass production machinery, can solve the problems of long cycle and cannot meet the requirements of online stacking cycle of float glass, etc., and achieves the effect of improving system life, simplifying structure and reducing friction damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] With reference to the drawings of specific embodiments of the present invention, the present invention will be described in more detail below. However, the present invention can be implemented in many different forms and should not be construed as being limited by the embodiments presented herein. On the contrary, these embodiments are proposed to achieve a full and complete disclosure, and to enable those skilled in the art to fully understand the scope of the present invention.

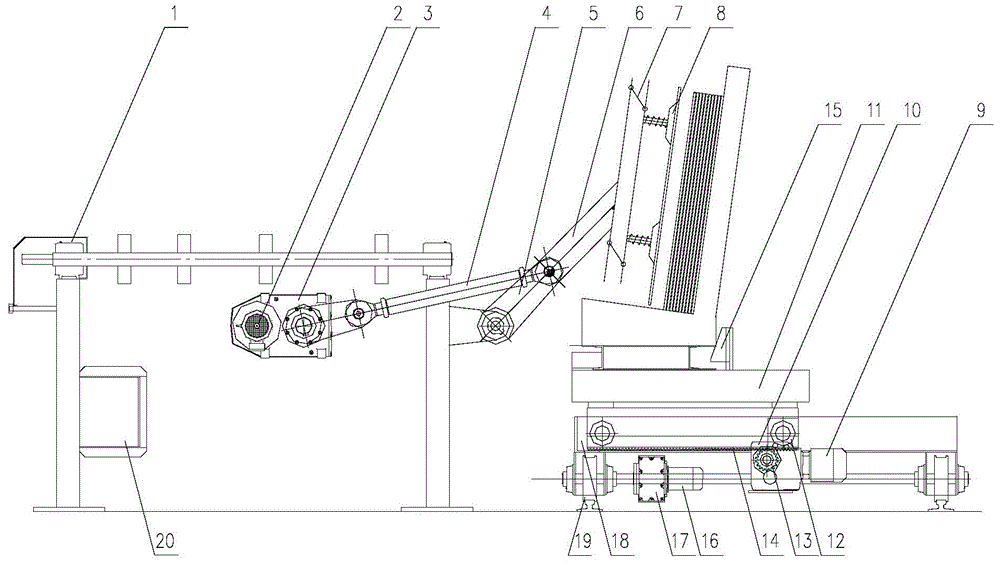

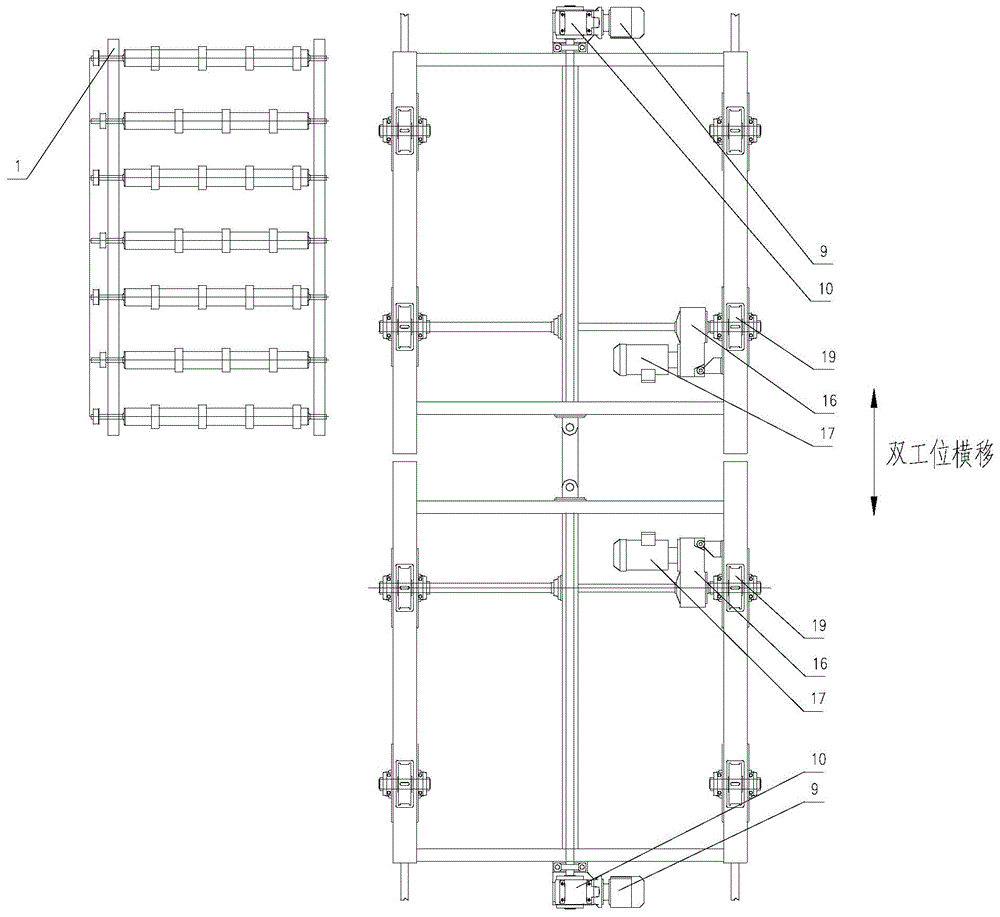

[0018] Now referring to the accompanying drawings, a vertical stacking system for offline flake removal of float glass according to an embodiment of the present invention will be described in detail.

[0019] The invention includes an overturning platform and a double-station stepping trolley, and the overturning platform and the double-station stepping trolley are coordinated by an electrical control system. The turning platform consists of a suction cup lifting mechanism, a fixed roller table, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com