Spinning machine drafting zone cleaning mechanism and cleaning method

A technology for cleaning mechanisms and spinning machines, applied to cleaning methods and appliances, cleaning methods using gas flow, chemical instruments and methods, etc., which can solve the problems of short effective blowing distance, low cleaning accuracy, and increased yarn defects , to achieve the effect of high utilization of blowing range, ideal cleaning effect and high cleaning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

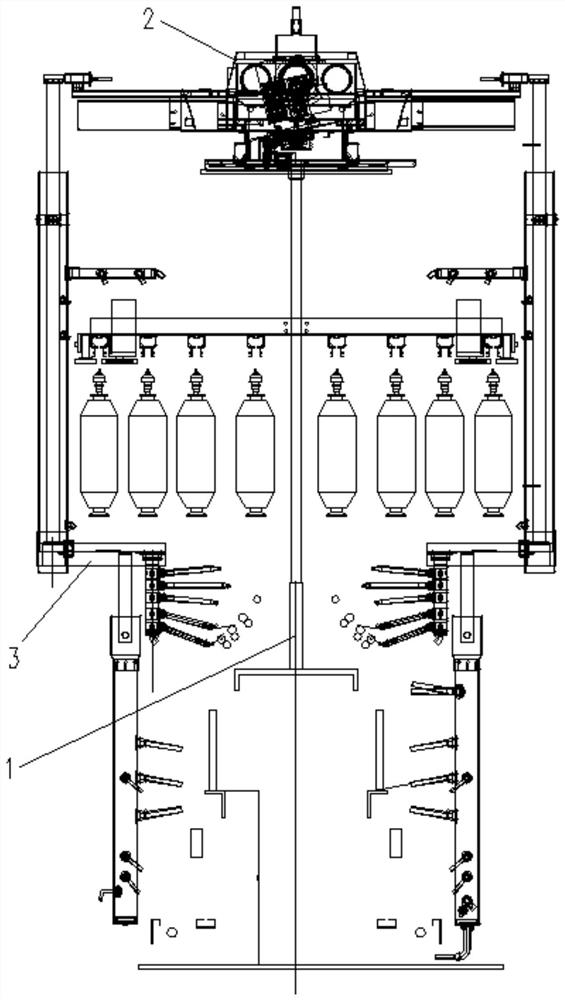

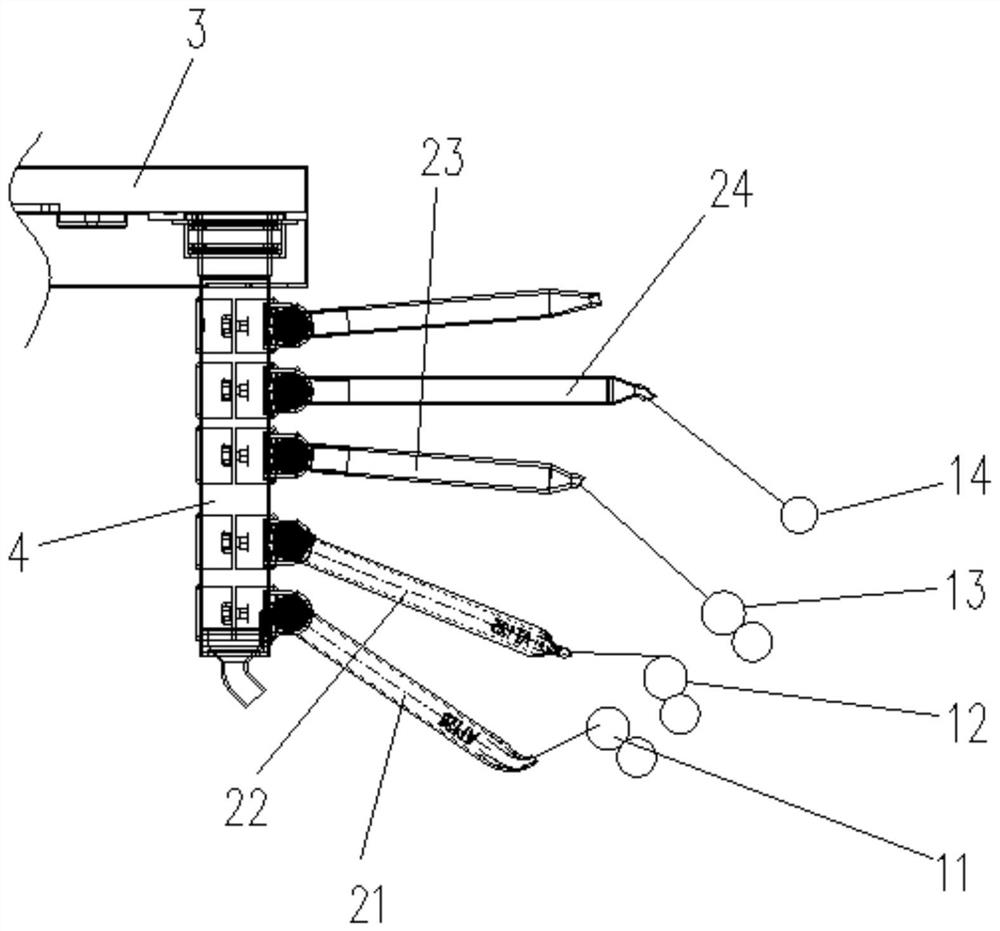

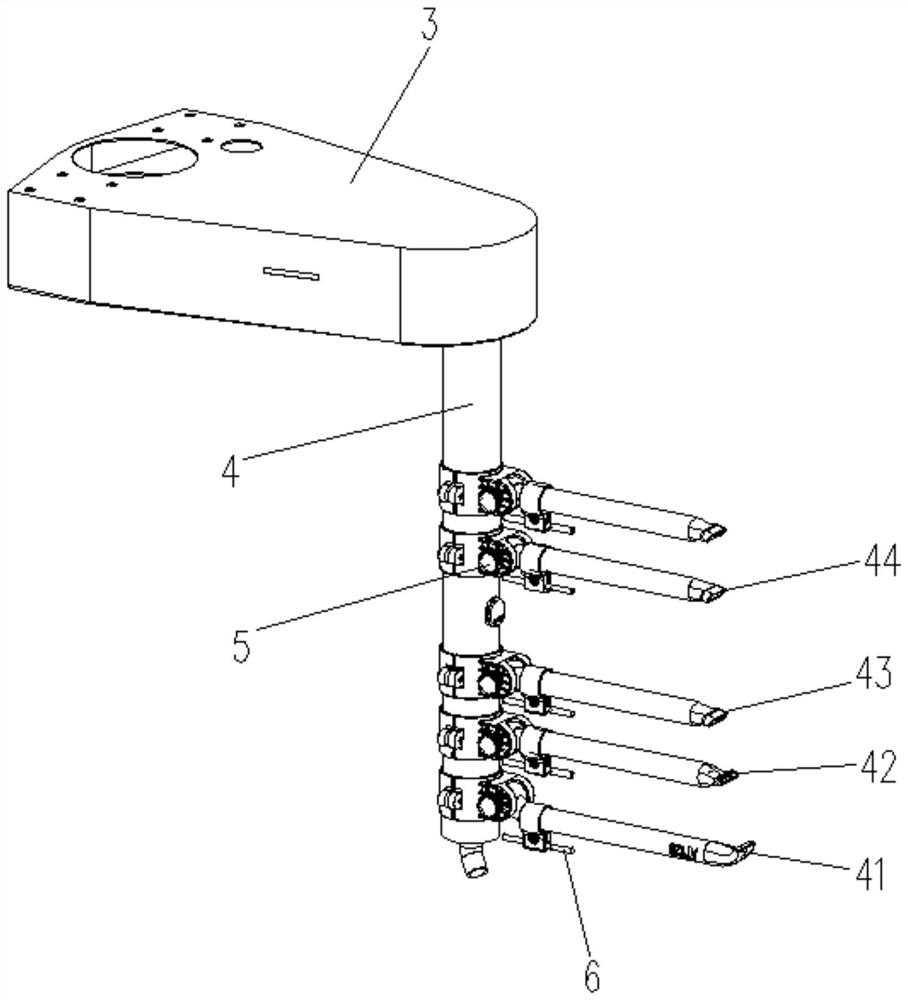

[0027] Embodiment: a kind of drafting area cleaning mechanism of spinning machine, such as Figure 1-4 As shown, the working areas on both sides of the spinning machine 1 are respectively provided with a first top roller bearing 11, a second top roller bearing 12, a third top roller bearing 13 and a fourth top roller bearing 14, which are relatively inclined from bottom to top, The area between the first top roller bearing 11 and the second top roller bearing 12 is a draft zone, and waste cotton is easily accumulated on the first top roller bearing 11 and the second top roller bearing 12 on both sides of this area, wherein It is even worse with the first top roller bearing 11, but the yarn in this region is easy to cause broken yarn or yarn defect when the blowing wind is strong.

[0028] In view of the above situation, the cleaning mechanism of this embodiment is provided with blowing components on both sides of the spinning machine 1 respectively. Since the blowing component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com