Reducing comb-type yarn controller

A controller, comb technology, applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of unstable tension, small or even just point holding, frequent instantaneous changes of yarn tension, etc. To achieve the effect of flexible adjustment angle, reduced yarn breakage and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

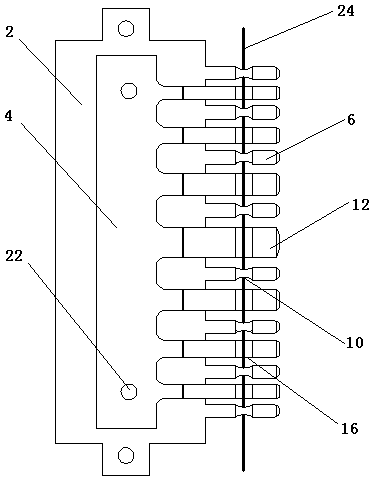

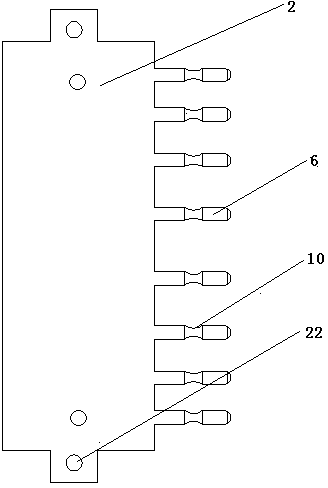

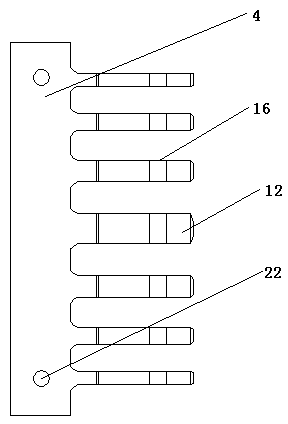

[0022] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, a radial variable comb type yarn controller includes: a fixed comb 2 and a plug-in comb 4 preferably fixedly connected together with two screws, and the fixing holes 20 provided at both ends of the fixed comb 2 are used to fix the The comb 2 is fixed on the machine, preferably the same side of the fixed comb 2 and the turning comb 4 are respectively provided with 8 first comb teeth 6 and a maximum of 7 second comb teeth 12, in order to prevent the yarn from swinging or slipping between the comb teeth The first comb tooth 6 is provided with a waist groove 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com