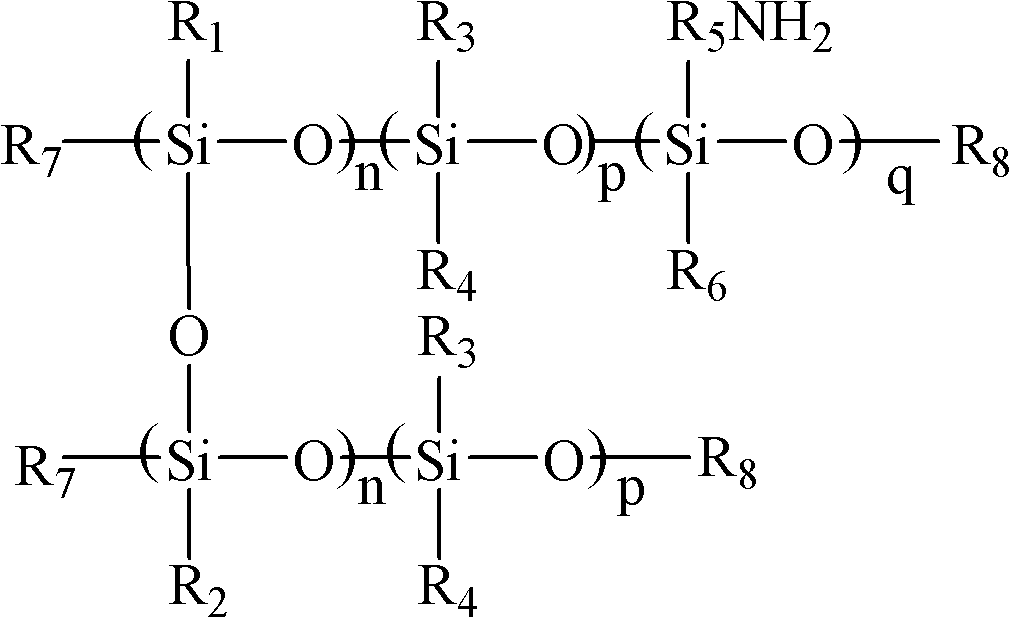

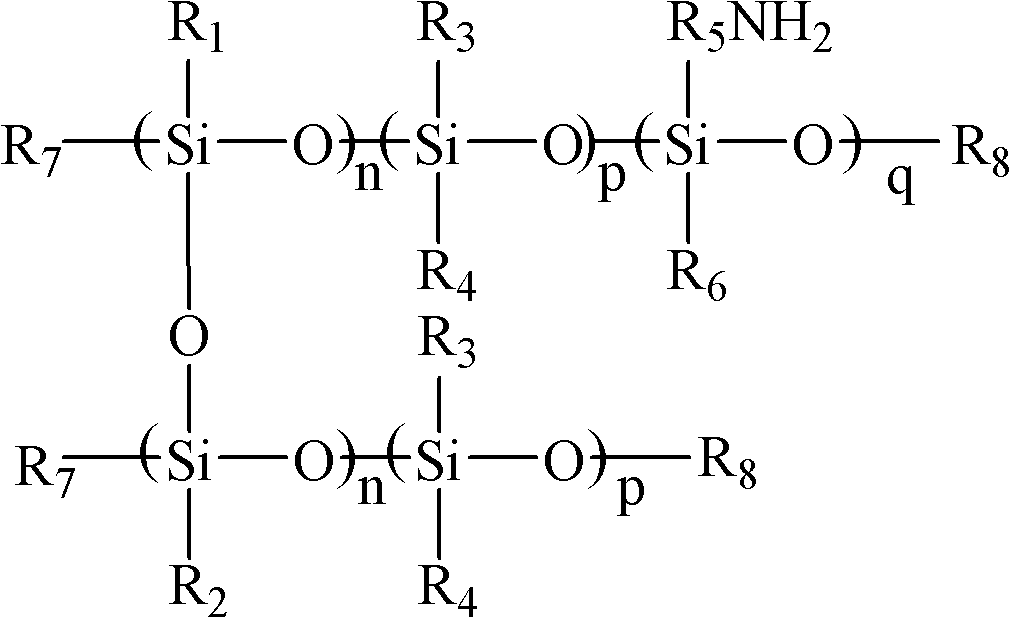

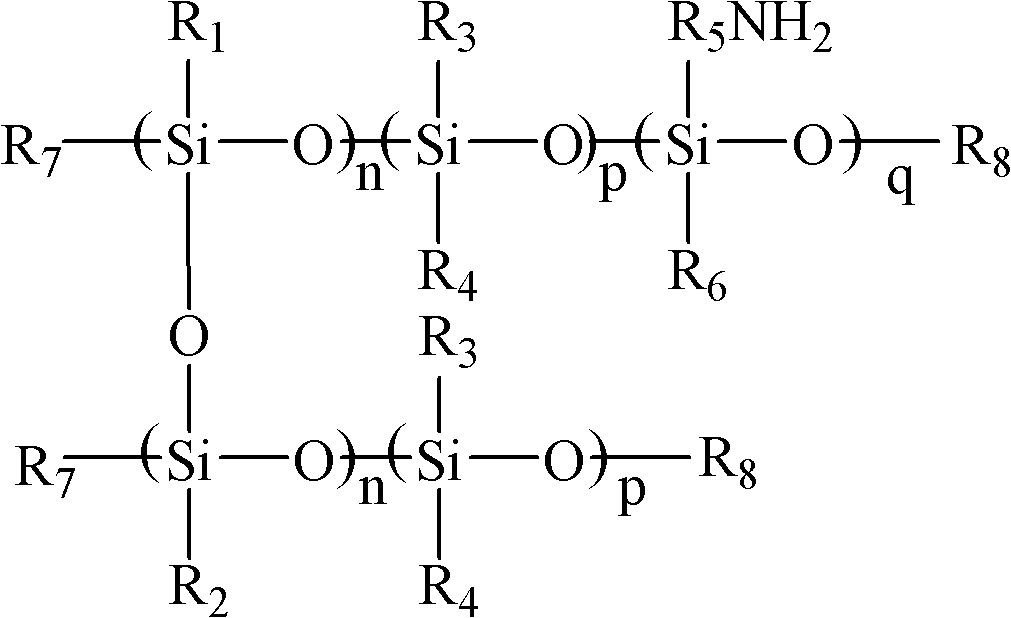

Amino-containing organic silicon resin fire retardant and preparation method thereof

A silicone and amino-containing technology, which is used in the field of flame retardants and their preparation, can solve the problems of poor thermal stability and flame retardancy, achieve improved mechanical properties and processing properties, less corrosive gases, and inhibit thermal oxidation degradation reactions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A 2000ml four-neck flask is equipped with a stirrer, a thermometer, a spherical condenser and a 500ml constant pressure funnel, and 300ml deionized water and 300ml xylene mixed solvent are added to prepare 41.2g N-β-aminoethyl-γ-aminopropyl methyl Dimethoxysilane, 16.8g methyltriethoxysilane and 211.2g diphenyldiethoxysilane were mixed evenly and added to the constant pressure funnel, the temperature was controlled at 40°C, and added dropwise to the flask at a constant speed , added dropwise for 40-50 minutes; continued hydrolysis for 6 hours, then added 60ml of 0.1mol / l hydrochloric acid solution for 4 hours of reaction, added 5.0 grams of hexamethyldisilazane, and reacted for 2 hours, then added 40ml of 0.1mol / l hydrogen Sodium oxide solution neutralized the reaction system, filtered, washed and dried to obtain a white resinous solid, which is an amino group-containing silicone resin. The mass is 194.8g, the yield is 92.3%, the number average molecular weight is about...

Embodiment 2

[0026] A 1000ml four-necked flask is equipped with a stirrer, a thermometer, a spherical condenser and a 100ml constant pressure funnel, and in 500ml deionized water and xylene mixed solvent (volume ratio 2: 1), 25.6 grams of aminopropylmethyl dimethyl Oxysilane, 8.4 grams of methyltriethoxysilane, and 106.5 grams of diphenyldiethoxysilane were mixed evenly and added to the constant pressure funnel. The reaction temperature was controlled at 60 ° C, and the solvent was added dropwise at a uniform speed. After 28-32 minutes, the dropwise addition is completed; continue hydrolysis for 3 hours, then add 30ml of 0.1mol / l sodium hydroxide solution, continue the reaction for 4 hours, add 4.0 grams of dimethyltetraphenyldisiloxane, and react for 2 hours, then add 0.1mol / l hydrochloric acid solution 30ml to neutralize the reaction system, filter, wash and dry to obtain a white resinous solid which is an amino group-containing silicone resin. The mass is 94.2 g, the yield is 89.2%, th...

Embodiment 3

[0028] A 1000ml four-neck flask is equipped with a stirrer, a thermometer, a spherical condenser and a 100ml constant pressure funnel, and 500ml of deionized water is added, and 60.4 grams of aminopropyltrimethoxysilane and 118.8 grams of phenyltrimethoxysilane are mixed evenly. Add it into a constant pressure funnel, control the reaction temperature at 50°C, add it dropwise to deionized water at a constant speed, and drop it in 30-45 minutes to complete the dropwise addition; continue hydrolysis for 4 hours, then add 25ml of 0.1mol / l sulfuric acid dilute solution, and continue the reaction for 4 hours Finally, add 4.0 g of dimethyltetraphenyldisiloxane, react for 2 hours, add 50 ml of 0.1 mol / l ammonia solution to neutralize the reaction system, filter, wash and dry to obtain a white resinous solid that is amino-containing organosilicon resin. The mass is 150.9 g, the yield is 88.7%, the number average molecular weight is 14000, and the structure is polysiloxane with branched...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com