Intelligent electricity-scalding cutting device

A cutting device and electric ironing technology, which is applied in the field of cutting devices and intelligent electric ironing machine cutting devices, can solve the problems of inconsistent product quality, low cutting efficiency, high labor cost, etc., and achieve the effect of saving labor costs, saving cutting materials, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

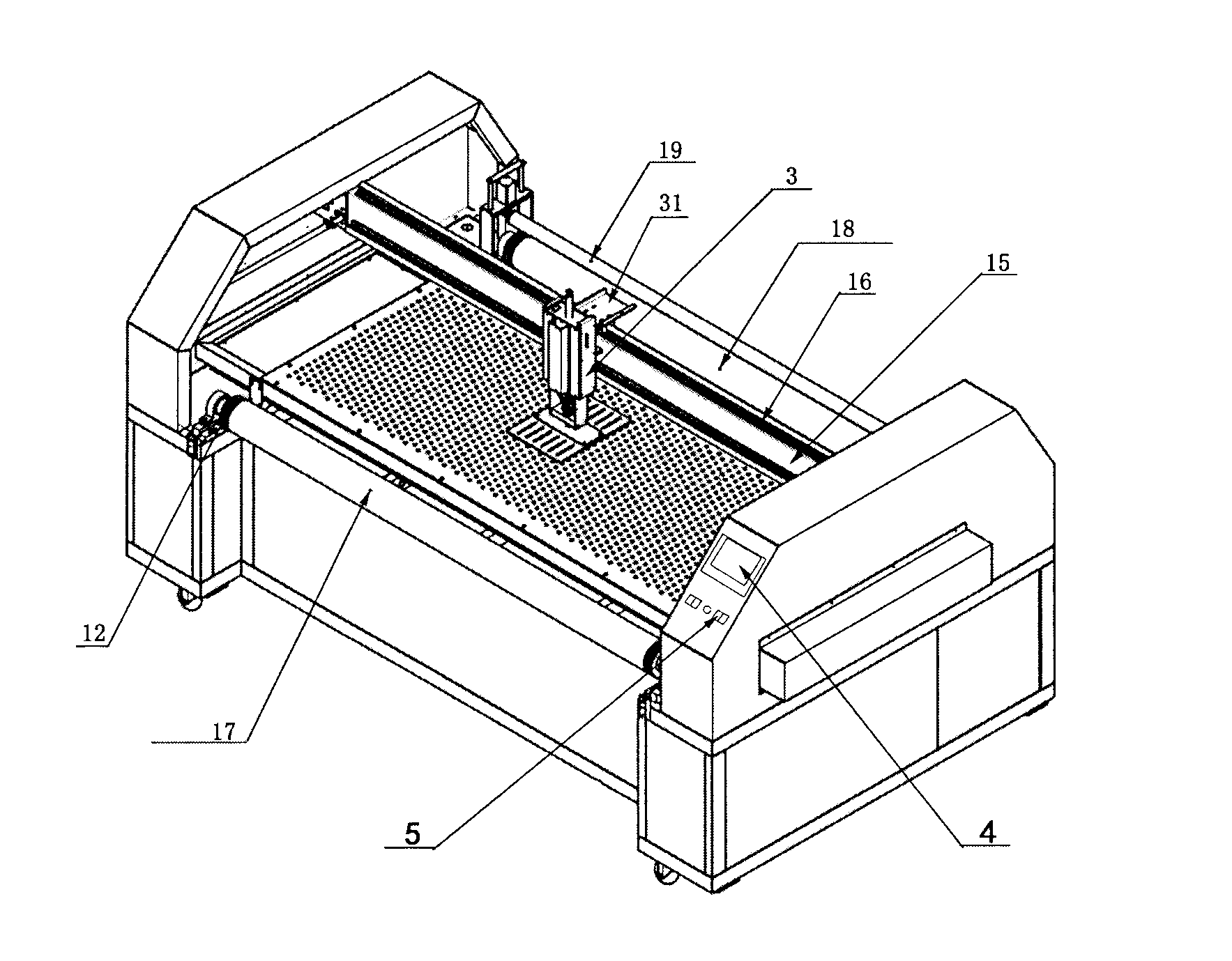

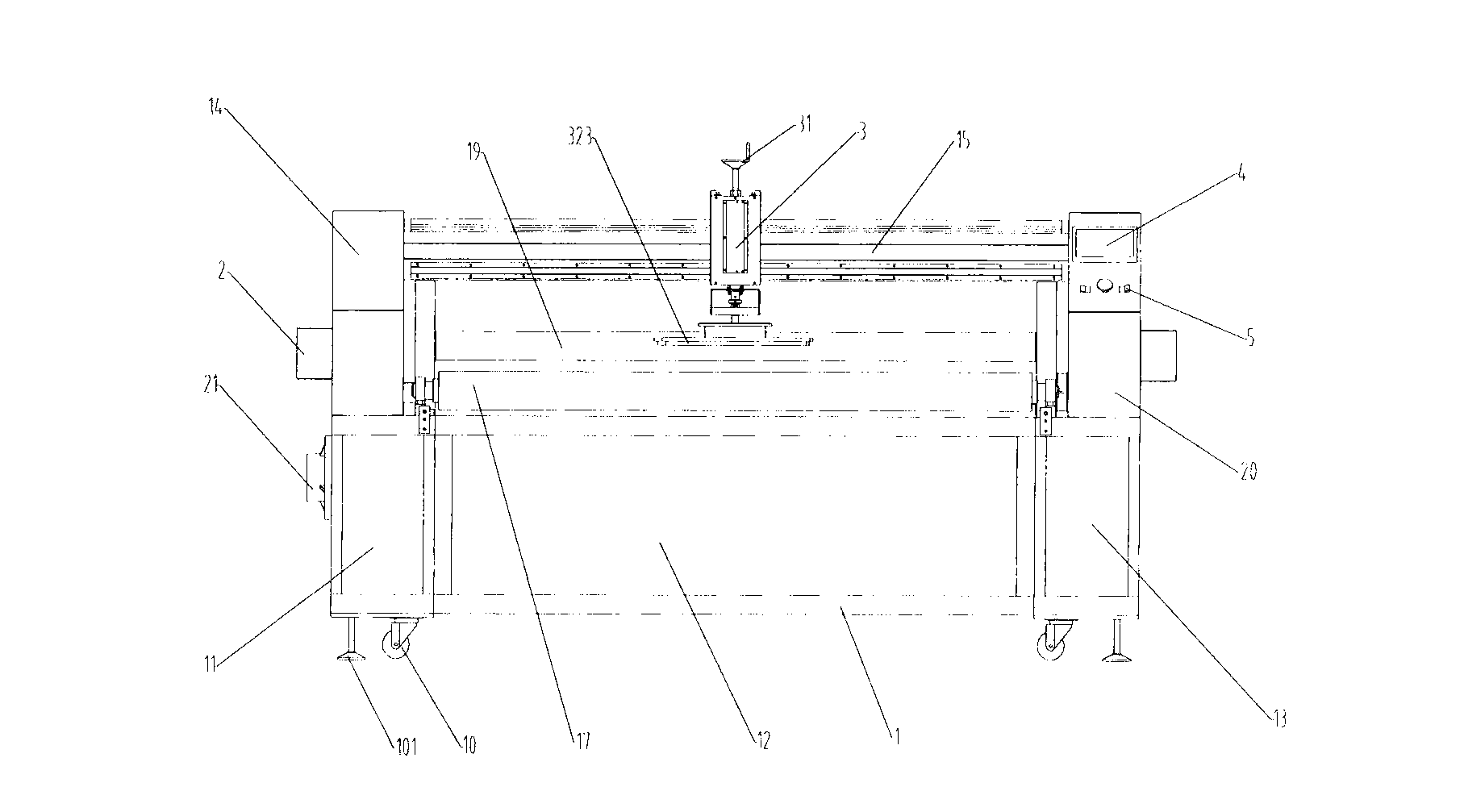

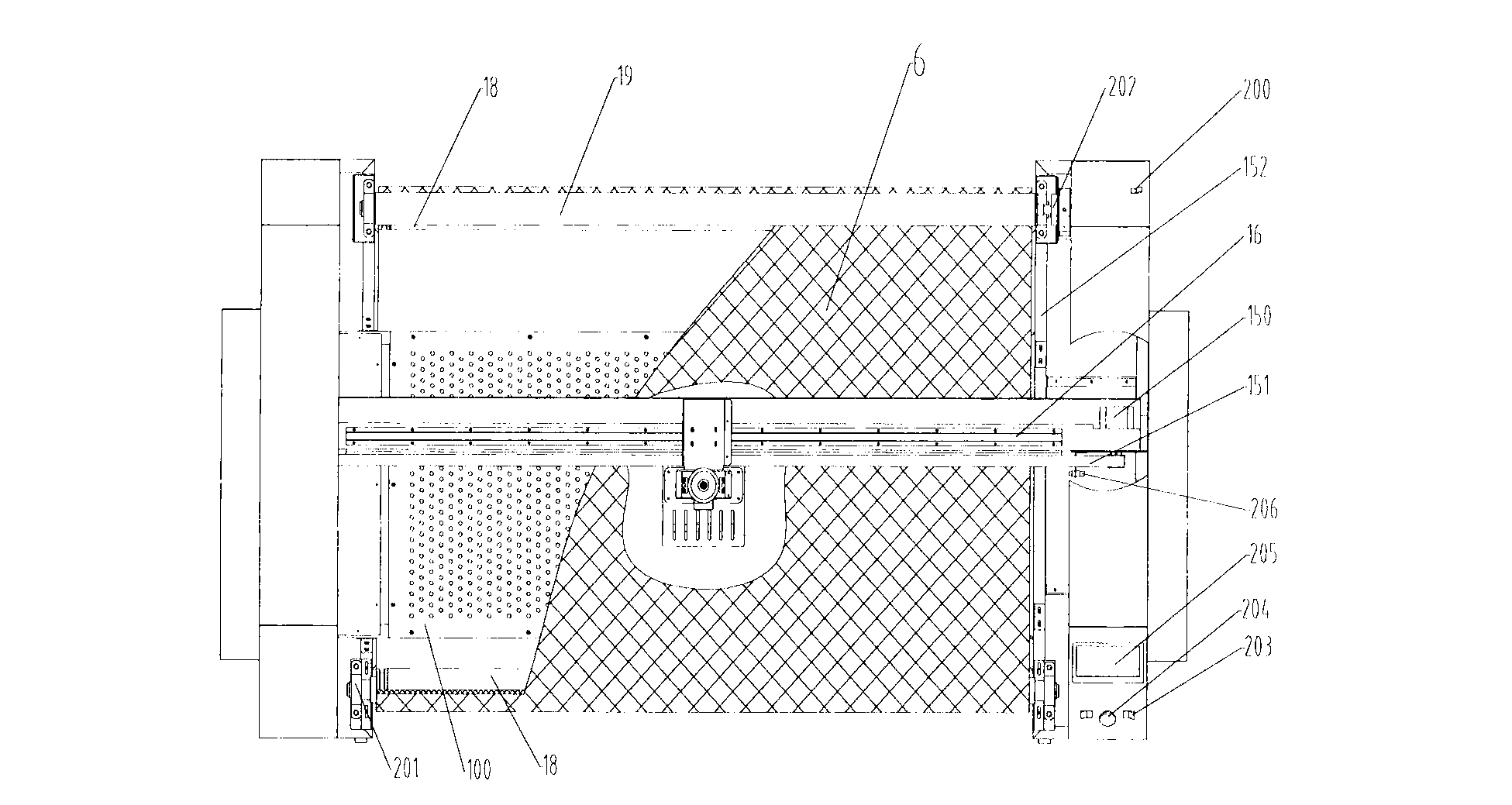

[0041] Below in conjunction with accompanying drawing and embodiment the present invention is further described and illustrated

[0042]In the figure: 1-main frame, 2-protective cover, 3-knife mechanism, 4-operation panel, 5-control switch, 6-transmission belt, 10-casters, 11-left box, 12-middle box, 13 -Right box, 14-left bracket, 15-beam, 16-guide rail, 17-driving roller, 18-driven roller, 19-roller, 20-right bracket, 21-air outlet, 31-fixed upper slider Frame, 100-exhaust air box, 101-machine foot, 150-motor, 151-synchronous belt one, 152-synchronous belt two, 200-cylinder control switch, 201-bearing, 202-control cylinder, 203-power switch, 204- Emergency switch, 205-touch screen, 206-proximity switch, 121-support plate, 122-small cover plate, 123-exhaust box, 124-mesh, 125-cover plate, 126-mesh plate, 201-bearing, 301- Pressing block, 302-adjusting screw, 303-polished rod pressing plate, 304-left cover plate, 305-bearing washer, 306-threaded plate, 307-right cover plate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com