Preparation method and application of chitosan haze settling agent

A technology of chitosan and sedimentation agent, which is applied in the field of preparation of chitosan haze sedimentation agent, can solve the problem that electricity consumption is not a small number, difficult problems, etc., achieve good adsorption and aggregation performance, wide sources, and accelerate aggregation and sedimentation. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

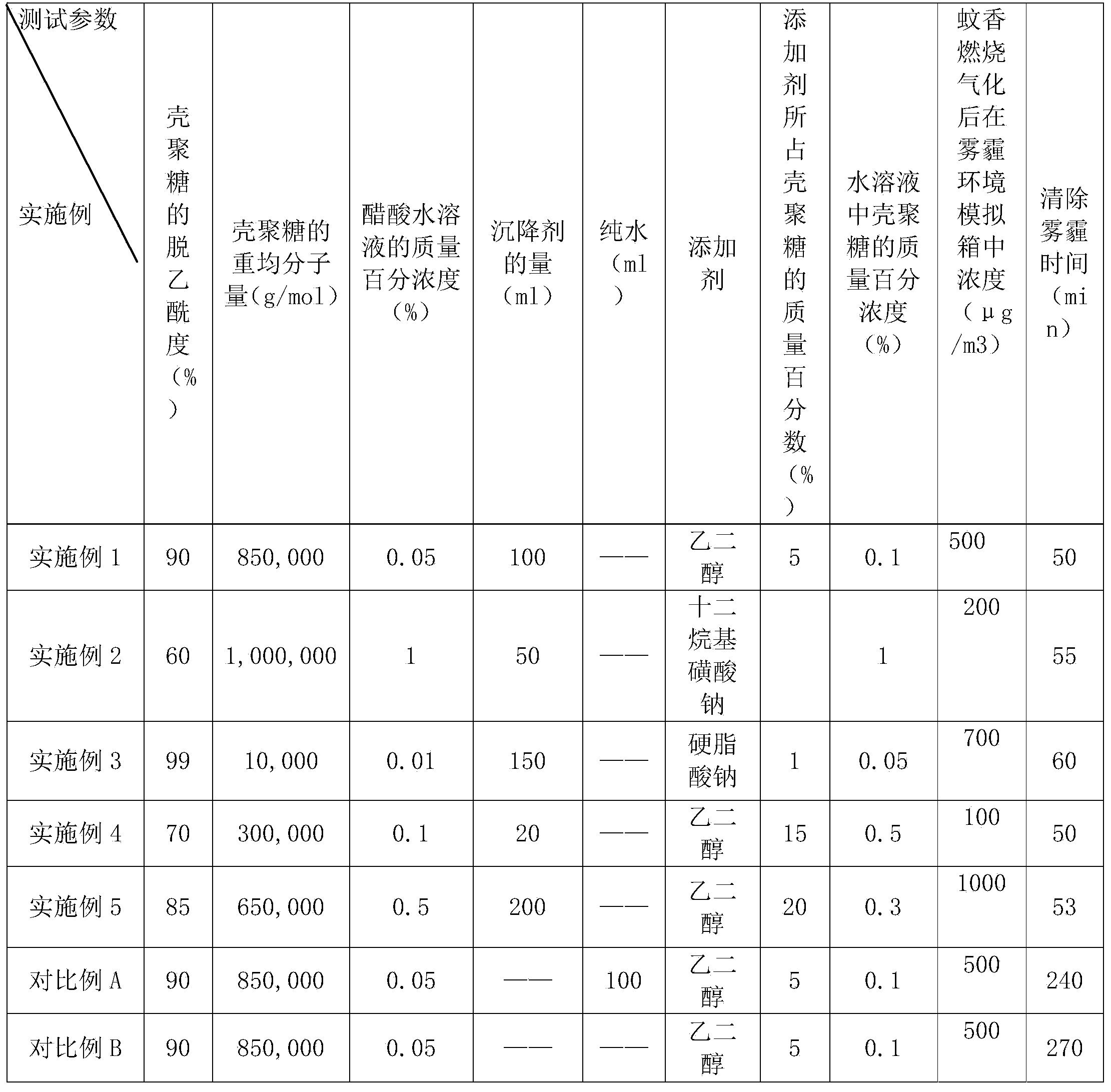

Embodiment 1

[0024] The chitosan that deacetylation degree is 90% is dissolved in 0.05% acetic acid aqueous solution in mass percent concentration, and the weight-average molecular weight of chitosan is 850,000g / mol, then adds ethylene glycol, and in the chitosan mixed solution, The mass percentage of the diol is 5%, and it is prepared into an aqueous solution containing chitosan with a mass percentage concentration of 0.1%, which is fully dissolved to prepare the chitosan smog settler. Then burn mosquito coils in the laboratory-made smog environment simulation box to simulate atmospheric smog, and the concentration of mosquito coils in the smog environment simulation box after combustion and gasification is 500 μg / m 3 , Spray 100mL of atomized chitosan sedimentation agent directly into the simulation box, and the time for clearing the haze is 50min.

[0025] The present invention specifically adopts chitosan as the atmospheric smog settlement agent, and chitosan is one of the most excelle...

Embodiment 2

[0033] The difference between embodiment 2 and embodiment 1 is: the chitosan that the degree of deacetylation is 60% is dissolved in the 1% acetic acid aqueous solution of mass percentage concentration, and the weight-average molecular weight of chitosan is 1,000,000g / mol, then add Sodium dodecyl sulfonate, the mass percentage of sodium dodecyl sulfonate in the chitosan mixed solution is 3%, and it is prepared into an aqueous solution containing chitosan with a mass percentage concentration of 1%, fully dissolved, and prepared Chitosan haze reducer. Then burn mosquito coils in the laboratory-made haze environment simulation box to simulate atmospheric haze, and the concentration of mosquito coils in the haze environment simulation box after combustion and gasification is 200 μg / m 3 , Spray 50mL of atomized chitosan sedimentation agent directly into the simulation box, and the time for clearing the haze is 55min. The test results are listed in Table 1.

Embodiment 3

[0035] The difference between embodiment 3 and embodiment 1 is: the chitosan that the degree of deacetylation is 99% is dissolved in the mass percent concentration and is 0.01% in the acetic acid aqueous solution, and the weight-average molecular weight of chitosan is 10,000g / mol, then add Sodium stearate, the mass percentage of sodium stearate in the chitosan mixed solution is 1%, is mixed with the aqueous solution that the mass percentage concentration containing chitosan is 0.05%, fully dissolves, and prepares the chitosan haze settlement agent. Then burn mosquito coils in the laboratory-made smog environment simulation box to simulate atmospheric smog, and the concentration of mosquito coils in the smog environment simulation box after combustion and gasification is 700 μg / m 3 , Spray 150mL of atomized chitosan sedimentation agent directly into the simulation box, and the time for clearing the haze is 60min. The test results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com