Nanometer silicon carbide-series infrared radiation coating and preparation method thereof

An infrared radiation coating and nano-silicon carbide-based technology are applied in the field of nano-silicon carbide infrared radiation coating and its preparation, which can solve the problems of unstable coating infrared radiation rate, decrease of infrared radiation rate, poor coating adhesion, etc. Excellent thermal shock resistance, improve infrared emissivity and absorption rate, and increase the effect of radiant heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

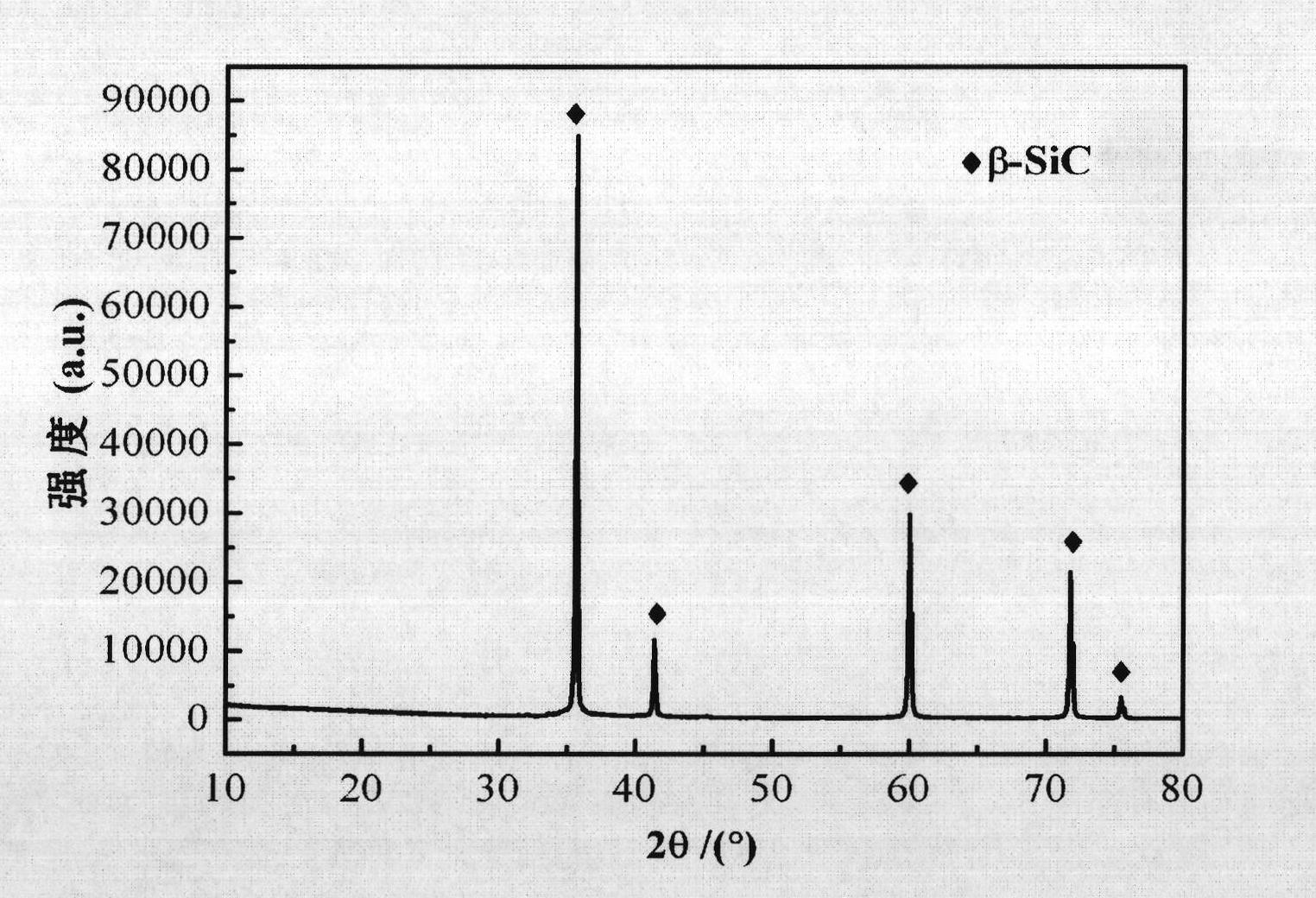

Embodiment 1

[0047] Take by weighing 3Kg of water glass with a mass percentage content of 30%, pour it into a container, add 6Kg of water, stir well, then add 100g of sodium hexametaphosphate and 20g of modified paraffin, stir well to obtain a liquid phase mixture; D. 50 100nm nano silicon carbide powder 4.5Kg, D 50 2.1Kg of 2μm zirconia powder, D 50 1Kg of 1.8μm chromium oxide powder, D 50 1.5Kg of 1μm iron oxide powder, D 50 0.8Kg bentonite powder of 1.2μm, D 50 0.5Kg of silica fume powder with a diameter of 1 μm was added into the container and stirred evenly to obtain a powder radiation material mixture. Fully mix the above-mentioned powder radiation material mixture and the liquid phase mixture together and put them into a horizontal sand mill with a ball-to-material ratio of 0.5:1, sand mill and homogenize for 3 hours, and filter through a 325-400 mesh screen After the treatment, the nano-silicon carbide-based infrared radiation coating is obtained.

[0048] According to the te...

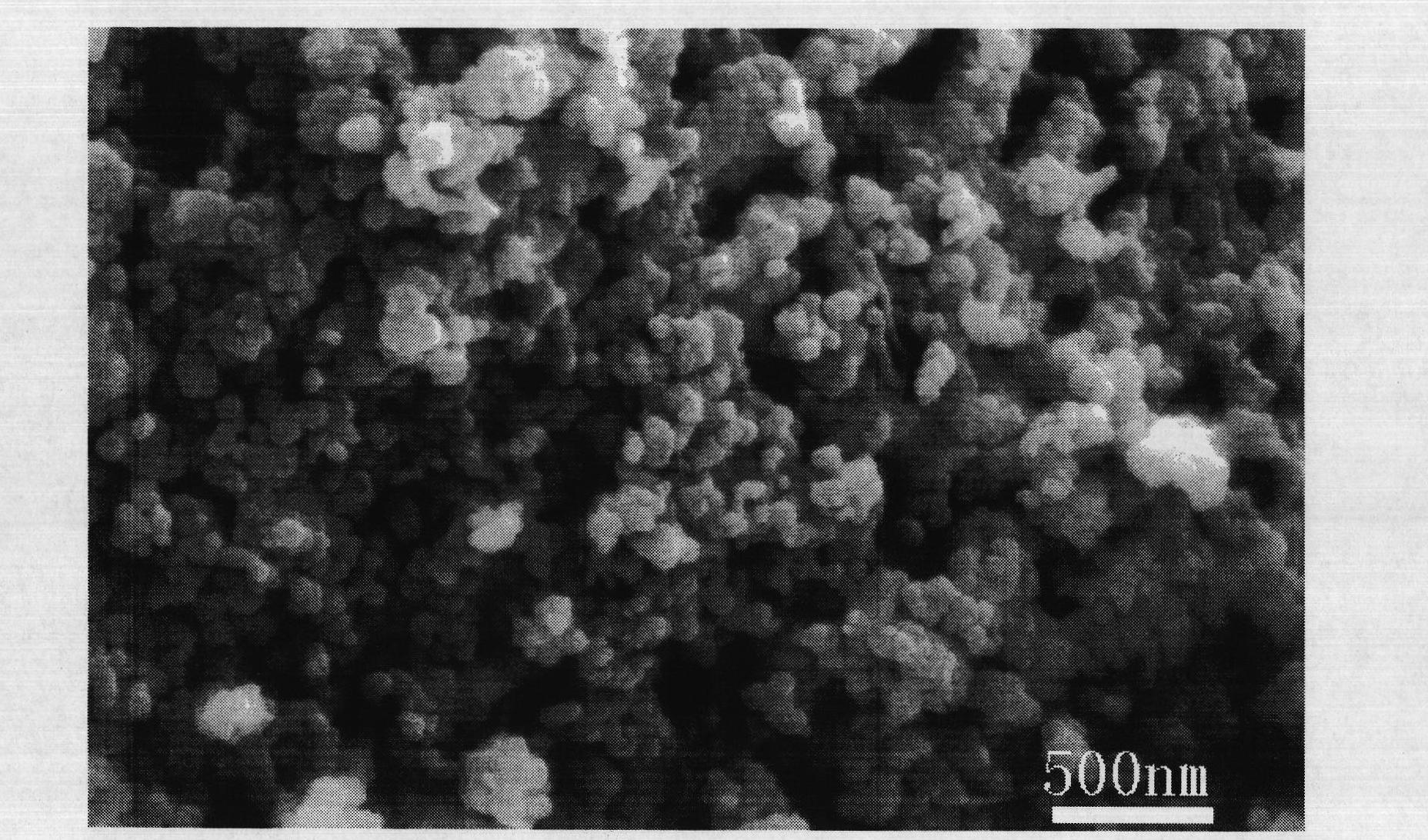

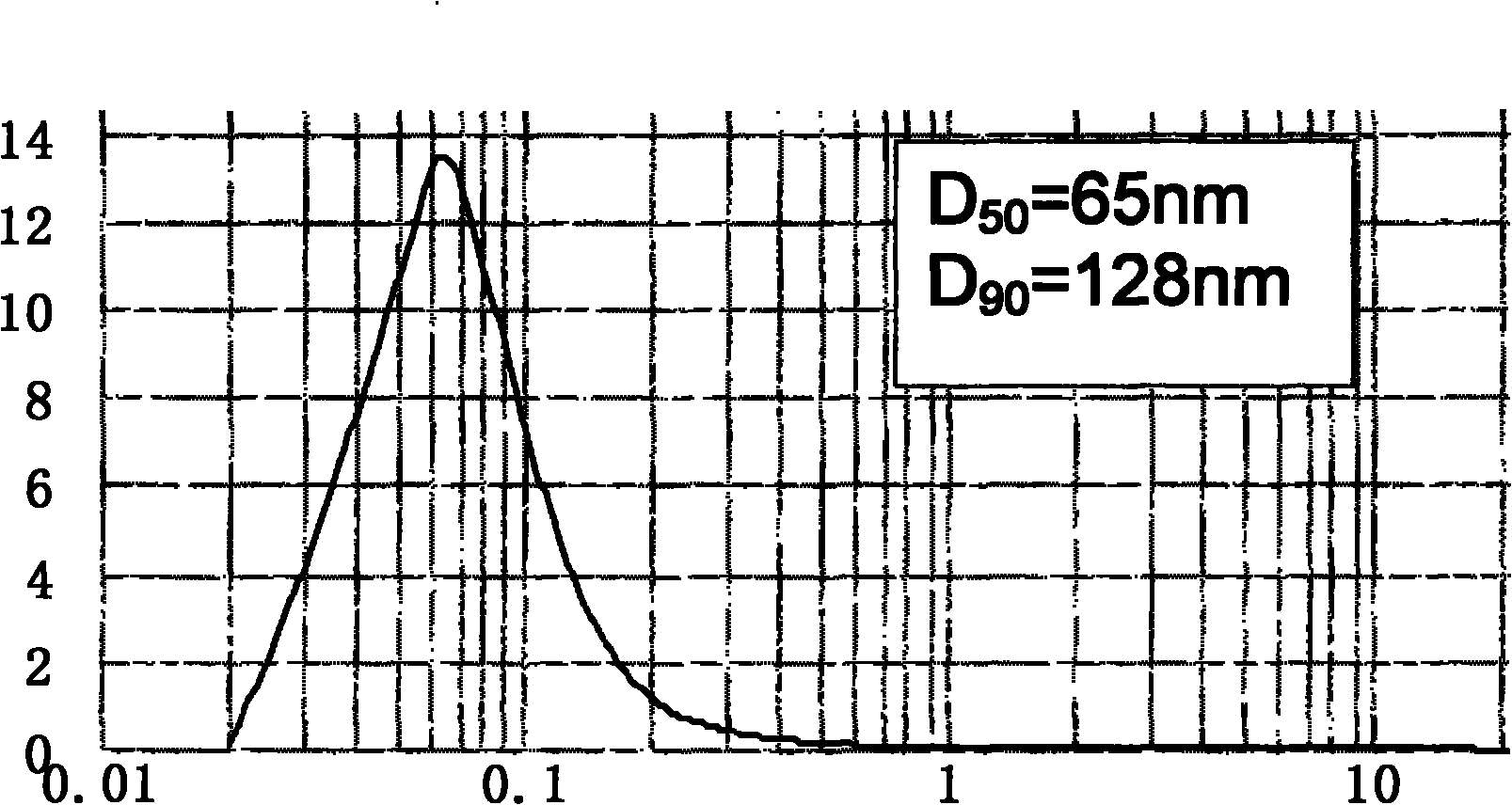

Embodiment 2

[0050] Weigh 2.5Kg of aluminum dihydrogen phosphate with a mass percentage of 30%, pour it into a stirring container, add 22Kg of water, stir evenly, then add 30g of sodium dodecylbenzenesulfonate and 15g of modified paraffin, stir Obtain the liquid phase mixture evenly; Weigh D 50 8Kg of nano-silicon carbide powder of 65nm, D 50 1.5μm zirconia powder 3Kg, D 50 1.5μm chromium oxide powder 0.5Kg, D 50 1Kg of 1μm iron oxide powder, D 50 0.6Kg bentonite powder of 1.2μm, D 50 0.5Kg of silica fume powder with a thickness of 1 μm was added into the container and stirred evenly to obtain a powder radiation material mixture. Fully mix the above-mentioned powder radiation material mixture and the liquid phase mixture together and put them into a vertical sand mill with a ball-to-material ratio of 1:1, sand mill and homogenize for 2 hours, and filter through a 325-400 mesh screen After the treatment, the nano-silicon carbide-based infrared radiation coating is obtained.

[0051] A...

Embodiment 3

[0053] Weigh 1.2Kg of silica sol with a mass percentage of 30%, pour it into a stirring container, add 6Kg of water, stir evenly, then add 200g of sodium polyacrylate and 80g of organic silicon, stir evenly to obtain a liquid phase mixture; weigh D 50 80nm nano silicon carbide powder 6.5Kg, D 50 2μm zirconia powder 1.5Kg, D 50 1.8μm chromium oxide powder 0.6Kg, D 50 0.5Kg of 1μm iron oxide powder, D 50 1Kg of 1.8μm nickel oxide powder, D 50 Bentonite powder 1.2μm 1Kg, D 50 0.3Kg of silica fume powder with a thickness of 1 μm was added into the container and stirred evenly to obtain a powder radiation material mixture. Fully mix the above-mentioned powder radiation material mixture and the liquid phase mixture together and put them into a pin-type sand mill with a ball-to-material ratio of 0.8:1. Sand mill and homogenize for 3 hours, and pass through a 325-400 mesh screen. After filtering, the nano-silicon carbide-based infrared radiation coating is obtained.

[0054] Acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com