Method for removing mercaptan in liquefied petroleum gas through catalysis

A liquefied petroleum gas and catalytic desulfurization technology, which is applied in the petroleum industry, gas fuel, fuel, etc., can solve the problems of thioetherification catalyst and no involvement, and achieve good economic and social benefits, low reaction temperature, high sulfur The effect of alcohol removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

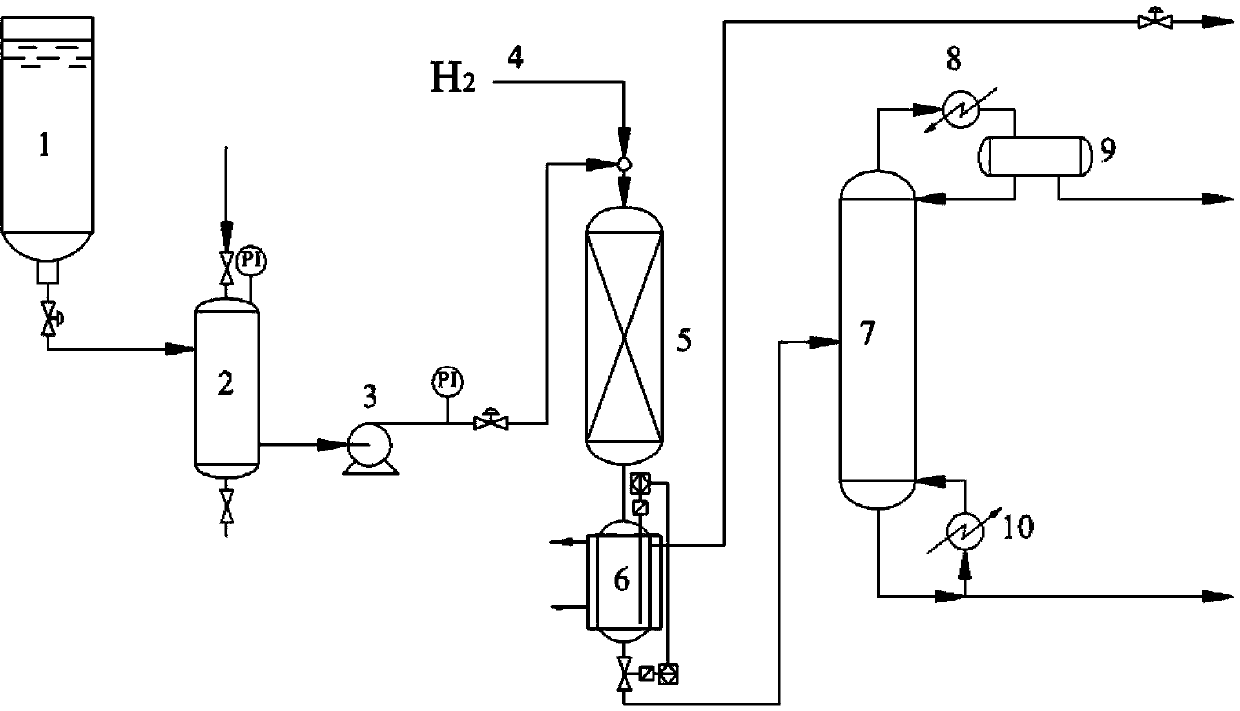

[0037] This embodiment provides a method for catalytic demercaptanization of liquefied petroleum gas, its technological process is as follows figure 1 As shown, the raw material of the liquefied petroleum gas is the liquefied petroleum gas after hydrogen sulfide removal and carbonyl sulfide treatment, and its composition is shown in Table 1.

[0038] Table 1

[0039] composition

content

Propane, %(v / v)

9.3

Propylene, %(v / v)

31.46

n-butane, %(v / v)

5.66

Isobutane, %(v / v)

25.07

1-Butene, %(v / v)

6.57

Isobutylene, %(v / v)

8.71

Cis-2-butene, %(v / v)

5.36

Trans-2-butene, %(v / v)

7.83

1,3-Butadiene, %(v / v)

0.03

Methyl mercaptan, μg / g

276.6

7.4

[0040] The method for catalytic sweetening of liquefied petroleum gas provided in this embodiment comprises the following steps:

[0041] The liquefied petroleum gas raw material ente...

Embodiment 2

[0051] This embodiment provides a method for catalytic demercaptanization of liquefied petroleum gas. Its operation steps are basically the same as in Embodiment 1. The liquefied petroleum gas mixture is carried out the distilling tower operation condition of fractionation treatment is identical with embodiment 1, and thioetherification catalyst still adopts Ni-Mo / SiO 2 -Al 2 o 3 system catalysts, the difference lies in the content of transition metals in the catalysts. Ni-Mo / SiO used in this example 2 -Al 2 o 3 In the system catalyst, based on the total weight of the catalyst, the composition content of the catalyst is: NiO 12.5wt%, MoO 3 8.5wt%, SiO 2 -Al 2 o 3 (including Al 2 o 3 87wt%, SiO 2 13wt%) 79wt%.

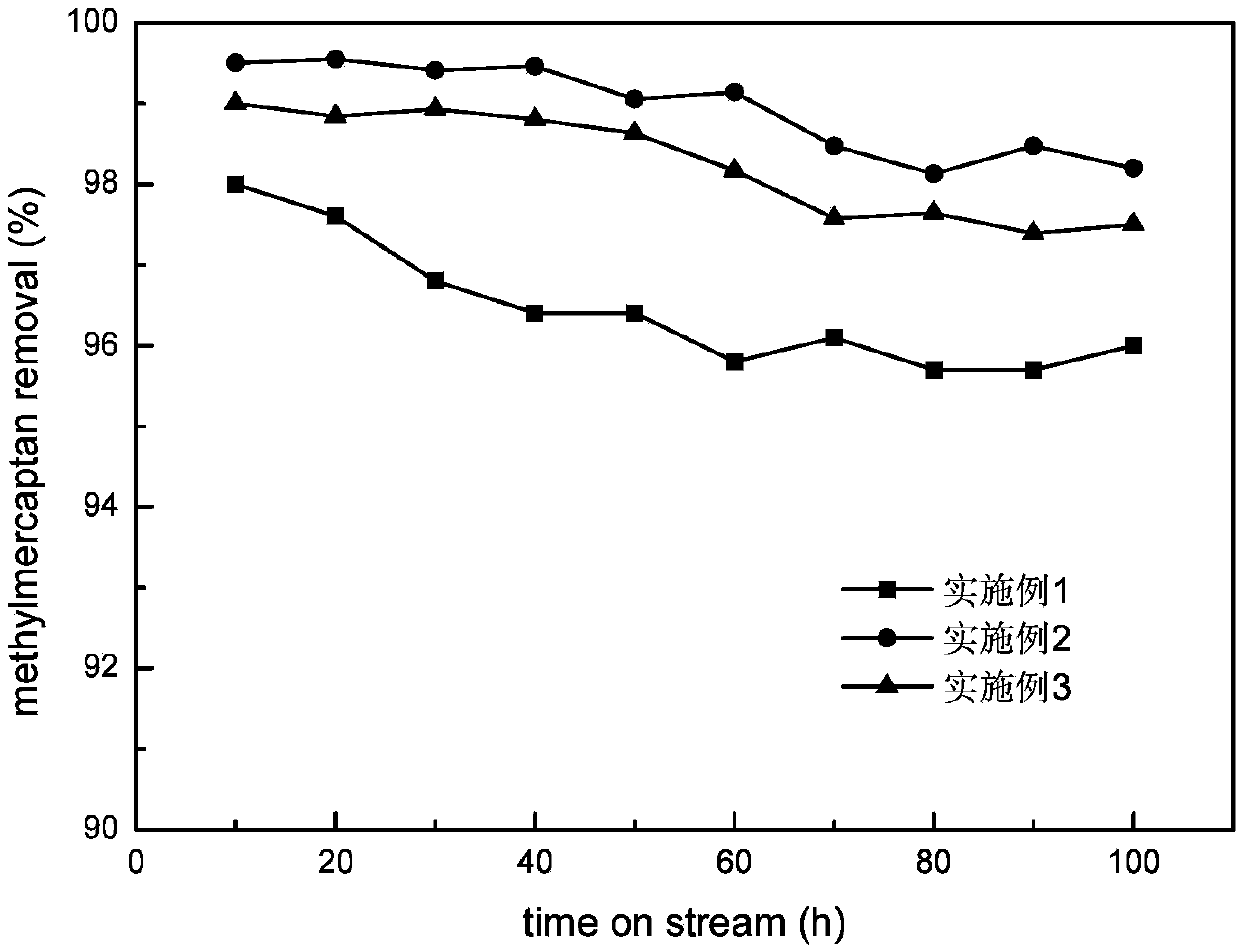

[0052] From figure 2 It can be seen from the figure that after the reaction lasted for 100 hours, the content of methyl mercaptan in the liquefied petroleum gas product after demercaptan removal at the top of the distillation column was measured to be 5.0 μg...

Embodiment 3

[0054] This embodiment provides a method for catalytic demercaptanization of liquefied petroleum gas, the operation steps of which are basically the same as in embodiment 1, and the loading amount of the catalyst used is the same as that of embodiment 1, the difference is that the composition of the liquefied petroleum gas raw material and the formazan The content of mercaptan sulfur is different, and the raw material composition is shown in Table 2; the thioetherification catalyst is Ni-W / SiO 2 -Al 2 o 3 System catalyst, the compound of transition metal nickel and tungsten is loaded on the carrier by the step-by-step impregnation method, based on the total weight of the catalyst, the composition content of the catalyst is: NiO 12wt%, WO 3 8wt%, SiO 2 -Al 2 o 3 Composite oxides (containing Al 2 o 3 87wt%, SiO 2 13wt%) 80wt%; the reaction temperature is 80°C, the reaction pressure is 2.0MPa, and the liquid volume space velocity is 2.5h -1 , the volume ratio of hydrogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com