Shipping ballast cabin coating composition

A technology for ballast tanks and compositions, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as easy seepage, affecting interlayer adhesion, easy yellowing, etc., to achieve good corrosion resistance, Excellent interlayer adhesion and anti-bleeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

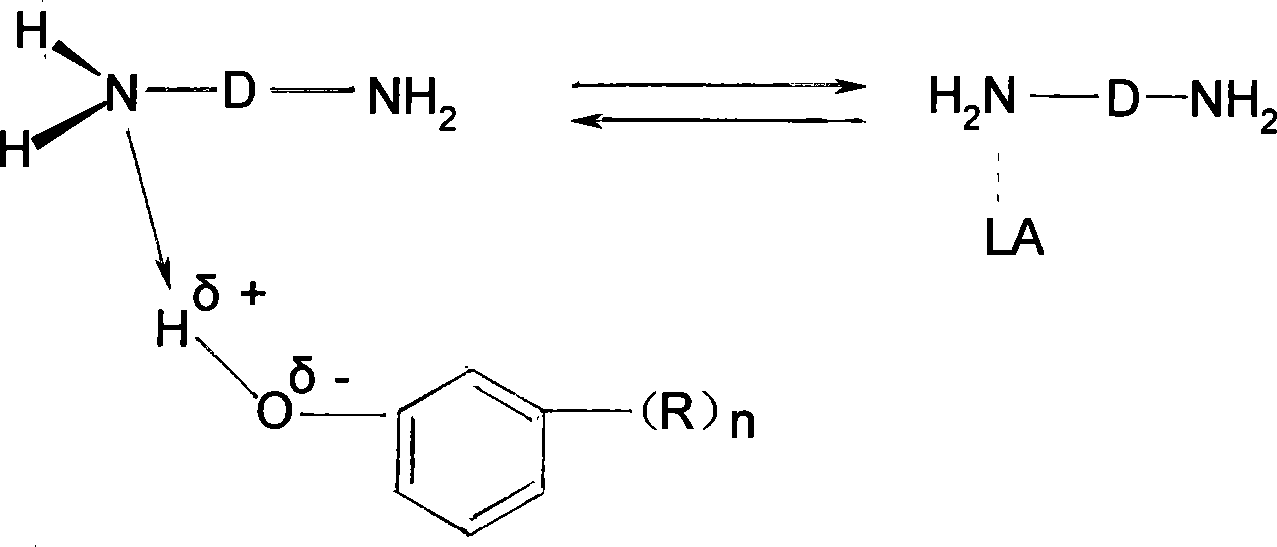

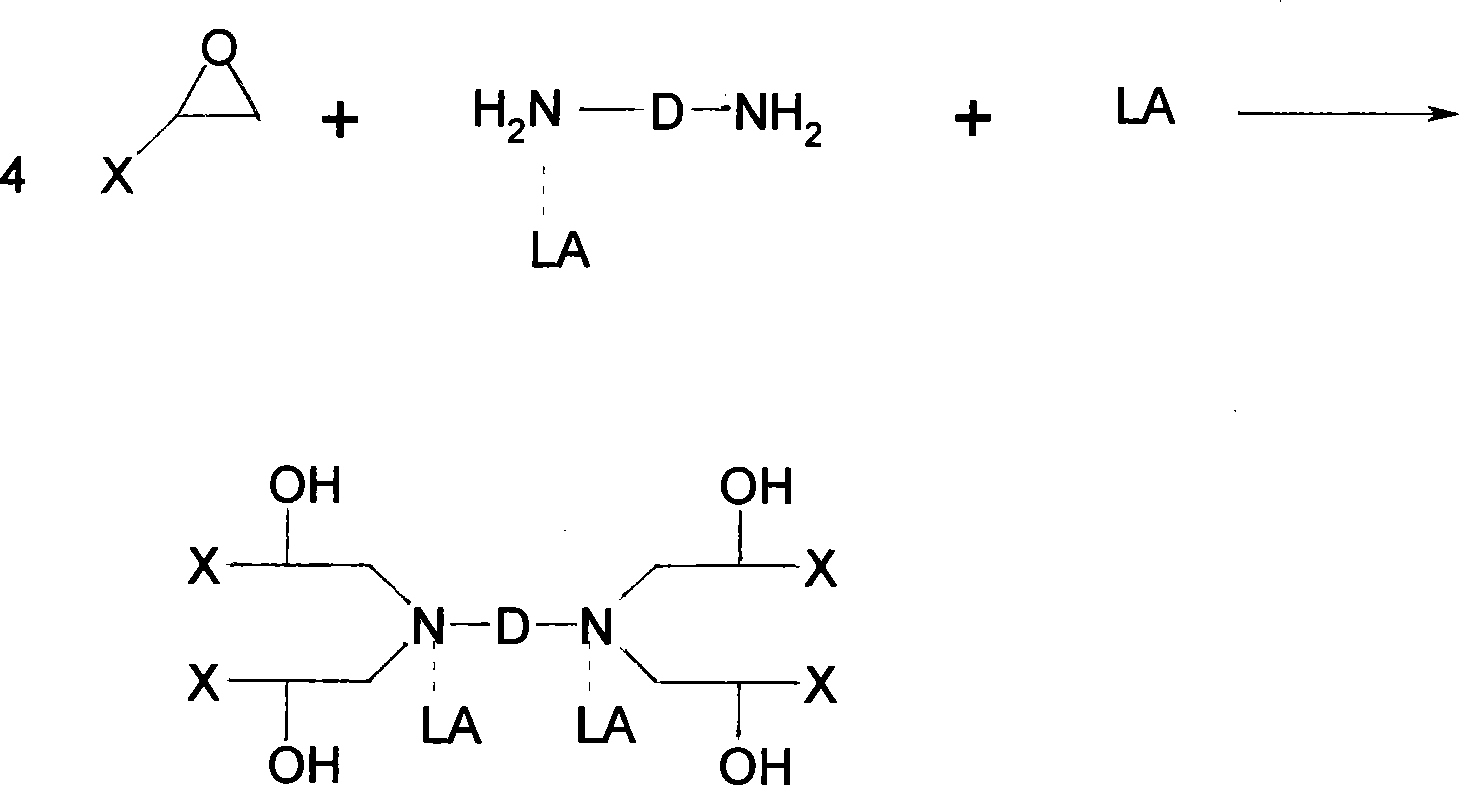

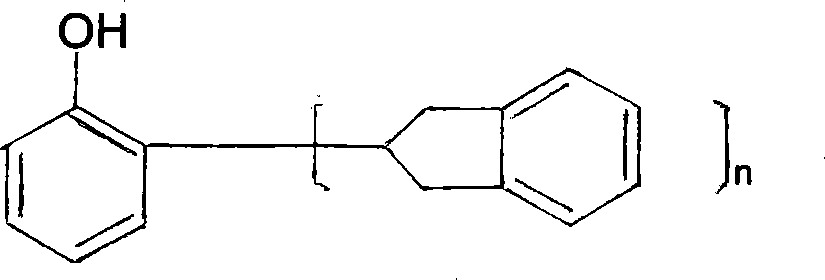

Method used

Image

Examples

Embodiment Construction

[0069] The composition of the present invention is composed of component A and component B. Therefore, it is prepared in two parts during specific preparation, and is placed in two containers. When used, the components A and B are mixed and coated. Protective film available.

[0070] 1. Preparation method:

[0071] Add 25 parts of special liquid petroleum resin, 20 parts of epoxy resin 1, 35 parts of epoxy resin 2, 25 parts of titanium dioxide, 30 parts of talcum powder, 1 part of anti-sagging agent, and 1 part of anti-settling agent in a 1000-liter reactor , 10 parts of xylene solvent, and then stirred at a high speed until the fineness is ≤50um, and then packaged separately to obtain the main ingredient component A.

[0072] Add 20 parts of solid agent 1 and 35 parts of solid agent 2 into a 1000-liter agitator, stir and disperse evenly, filter and package, and obtain component B.

[0073] 2. Coating method:

[0074] The composition of the present invention is composed of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com